AIRMAR

®

TECHNOLOGY CORPORATION

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

■

www.airmar.com

4

Copyright 1999. All rights reserved.

8. Lubricate the O-ring with mineral oil. This will help to seal the

assembly and prevent the mineral oil from leaking. Slide the

O-ring onto the transducer assembly (see Figure 7).

9. After the sealant on the base has cured, pour 71ml (2.4 fl. oz.)

of mineral oil into the base.

10.Lock the transducer assembly into the base by inserting the

keys on the locking ring in the notches in the base. Press down

and rotate clockwise until seated (see Figure 6).

11.Route the cable to the echosounder

being careful

not to tear

the cable jacket when passing it through the bulkhead and other

parts of the boat. To reduce electrical interference, separate the

sensor cable from other electrical wiring and sources of

electrical noise.

Note

: Some transducers are equipped with a short cable, about

1m (3'), and an extension cable. Be sure to locate the mated 3

pin connectors

well above the bilge waterline

. To facilitate

this, use one of the two cable clamps supplied on either side of

the connection.

Installation in a Cored Fiberglass Hull

Installation in a cored hull is difficult. The objective is to bond the

sensor to the

inside surface of the hull’s outer skin

while

preventing any moisture from penetrating the core.

Caution

: There is no way to determine if the outer skin is solid (no

trapped air bubbles in the fiberglass) at the selected location

before cutting the inner skin.

Warning

: Always wear safety goggles and a dust mask.

1. Using a 100mm

or

4" hole saw, cut through the

inner

skin and

the core at the selected location (see Figure 8). The core

material can be very soft. Apply only light pressure to the hole

saw after cutting through the inner skin to avoid accidentally

cutting the outer hull.

2. Remove the plug of core material, so the inner core of the hull is

fully exposed. Sand the

inside surface of the outer skin

using

a miniature disk sander. Slightly undercut the surrounding

coring if possible.

3. Clean and dry both the

inside surface of the outer skin

and

the housing with a weak solvent, such as alcohol, to remove

any dust, grease, or oil.

4. Place the base in the cavity. Fill the gap between the base and

the hull with casting epoxy or resin following the manufacturer’s

directions for its use.

5. After the casting epoxy or resin has cured, proceed with

“Installation”, on page 3.

Replacement Parts

To obtain a replacement base and O-ring, order part number

33-268-01 from your marine dealer or instrument manufacturer.

Transducer Replacement

The information needed to order a replacement sensor is printed

on the cable tag.

Do not

remove this tag. When ordering, specify

the part number, date, and frequency in kHz. For convenient

reference, record this information on the top of page one.

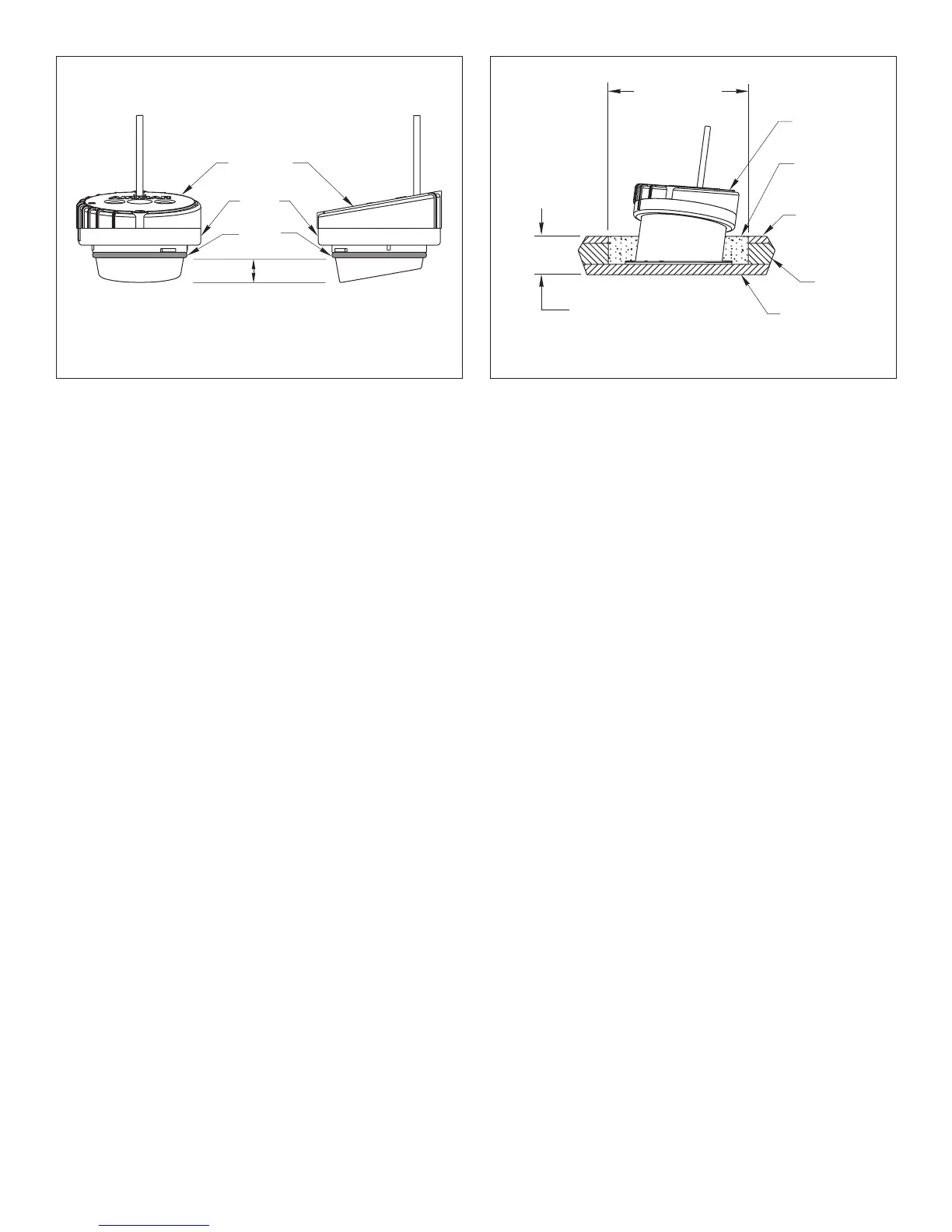

Figure 8. Installation in a cored fiberglass hull

transducer

i

nner skin

core

outer skin

fill with

casting epoxy

or resin

hull thickness

assembly

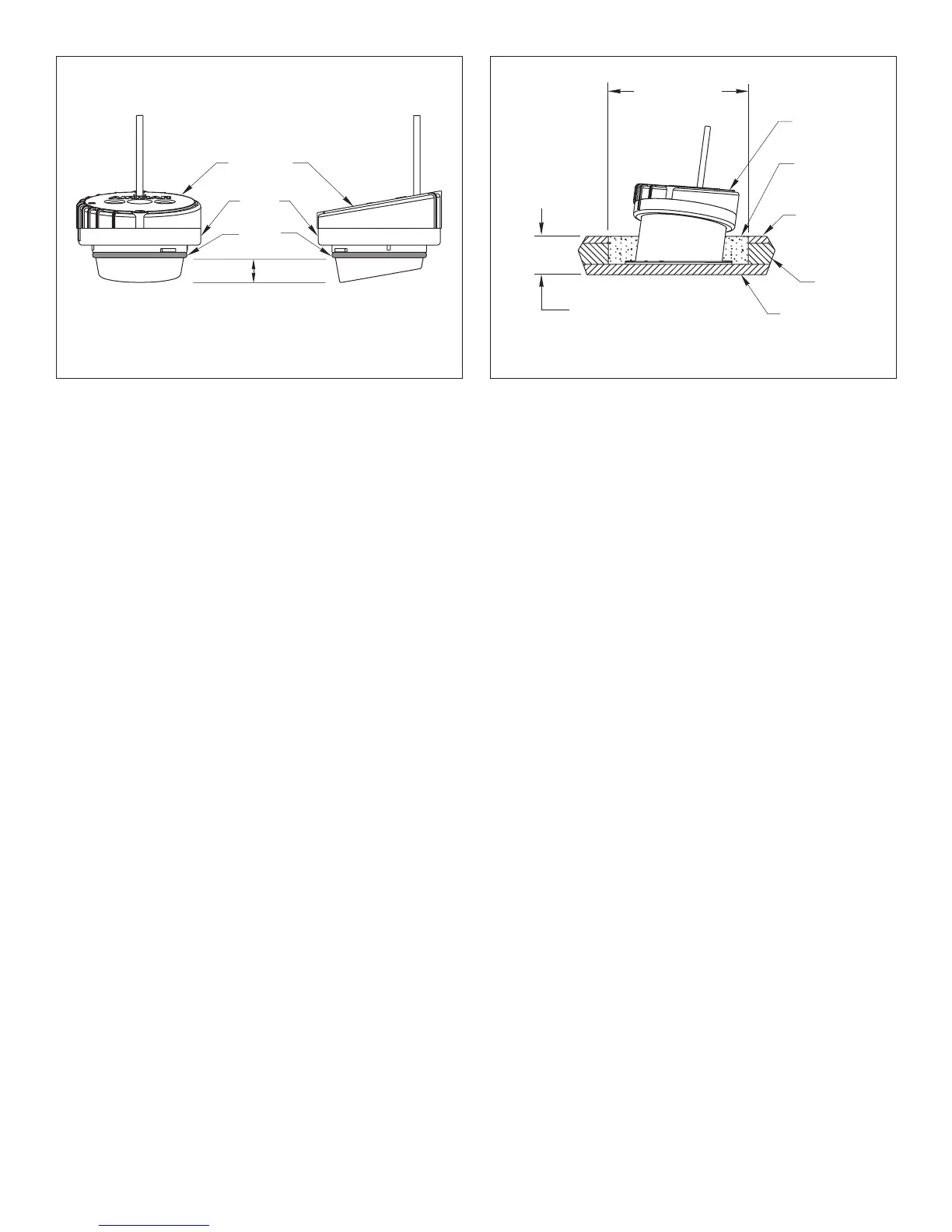

Figure 7. Installing the O-ring

O-ring

transducer

100mm (4")

front view

side view

locking

ring

Note: lubricate the O-ring with

mineral oil before sliding it onto

the transducer assembly

AIRMAR

®

AIRMAR

®

Loading...

Loading...