Mounting Location

• The water flowing across the hull

must

be smooth with a

minimum of bubbles and turbulence (especially at high speeds).

Caution

: DO NOT MOUNT near water intake or discharge

openings or behind strakes, fittings, or hull irregularities.

• The multisensor

must

be continuously immersed in water.

• The transducer beam

must

be unobstructed by the keel or

propeller shaft(s).

• Choose a location away from interference caused by power and

radiation sources such as: the propeller(s) and shaft(s), other

machinery, other echosounders, and other cables. The lower

the noise level, the higher the echosounder gain setting that

can be used.

• Choose a location with a minimum deadrise angle.

• Choose an accessible spot inside the vessel with adequate

headroom for the height of the housing, tightening the nuts, and

removing the insert.

Model

Min. with fairing

B744V 255mm (10")

B744VL 381mm (15")

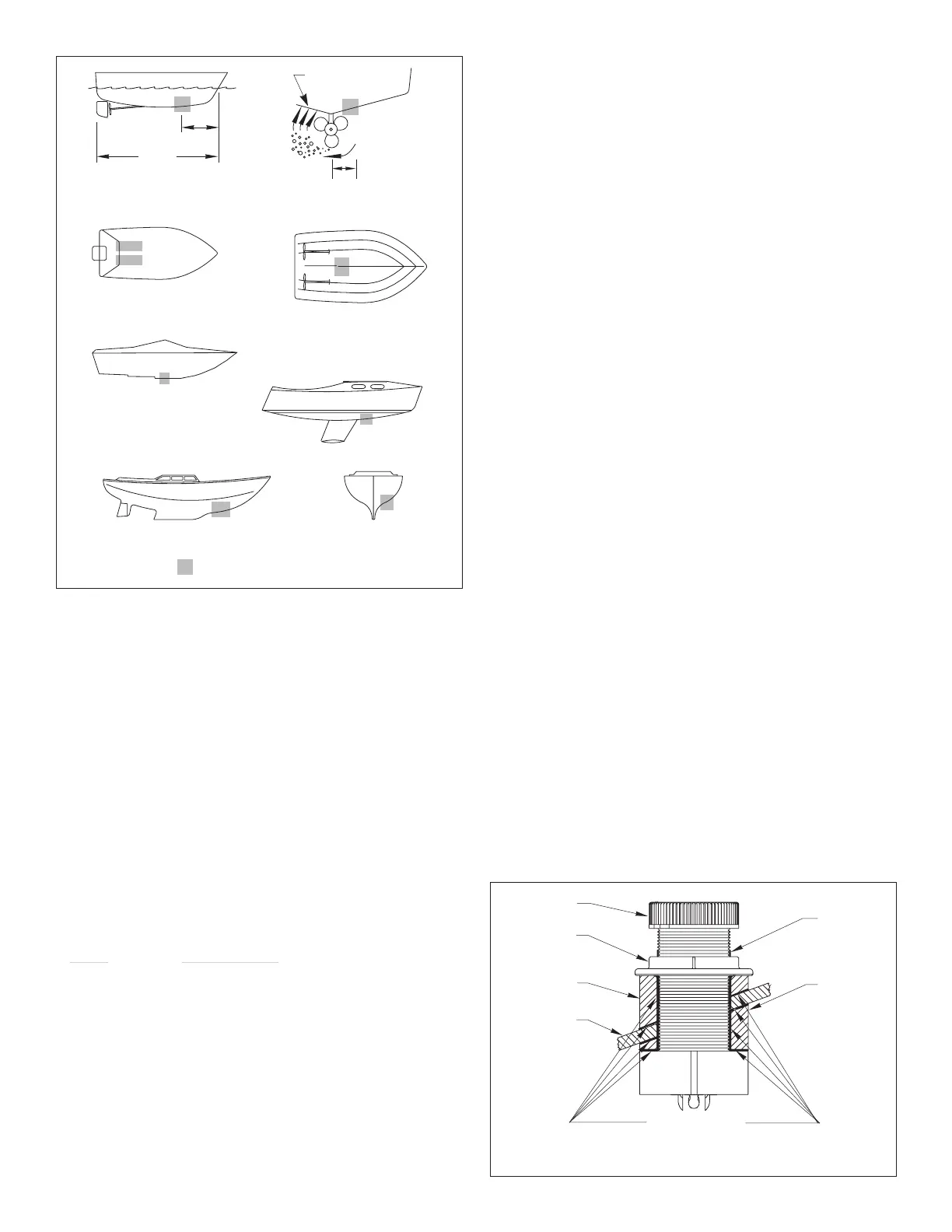

Hull Types

(see Figure 1)

•

Displacement hull powerboat

—Locate 1/3 aft LWL and

150–300mm (6–12") off the centerline. The starboard side of

the hull where the propeller blades are moving downward is

preferred.

•

Planing hull powerboat

—Mount well aft near the centerline and

well inboard of the first set of lifting strake

s to insure that it is in

contact with the water at high speeds. The starboard side of the

hull where the propeller blades are moving downward is preferred.

Outboard and I/O

—Mount forward and to the side of the engine(s).

Inboard

—Mount well ahead of the propeller(s) and shaft(s).

Stepped hull

—Mount just ahead of the first step.

Boats capable of speeds above 25kn

(29MPH)—Review

multisensor location and operating results of similar boats before

proceeding.

•

Fin keel sailboats

—Mount to the side of the centerline and

forward of the fin keel 300–600mm (1–2').

•

Full keel sailboats

—Locate amidships and away from the keel

at the point of minimum deadrise angle.

Installation

The following instructions are for a Standard Fairing ONLY.

WARNING

: The B744V and B744VL

must be installed with a

fairing (High-Performance or Standard). If the multisensor is

installed without a fairing, there is insufficient surface area

around the drilled hole to seal it to the hull. Water may leak

into the hull causing damage to the boat or possibly sinking.

WARNING

:

A High-Performance Fairing

must be installed

following the installation instructions that come with the fairing. The

High-Performance Fairing requires an anti-rotation bolt. Failure to

install the anti-rotation bolt may result in the fairing rotating while

the boat is underway. The effect may be violent movement and loss

of steering. This could result in serious injury or death to

passengers and/or damage to the boat or other property.

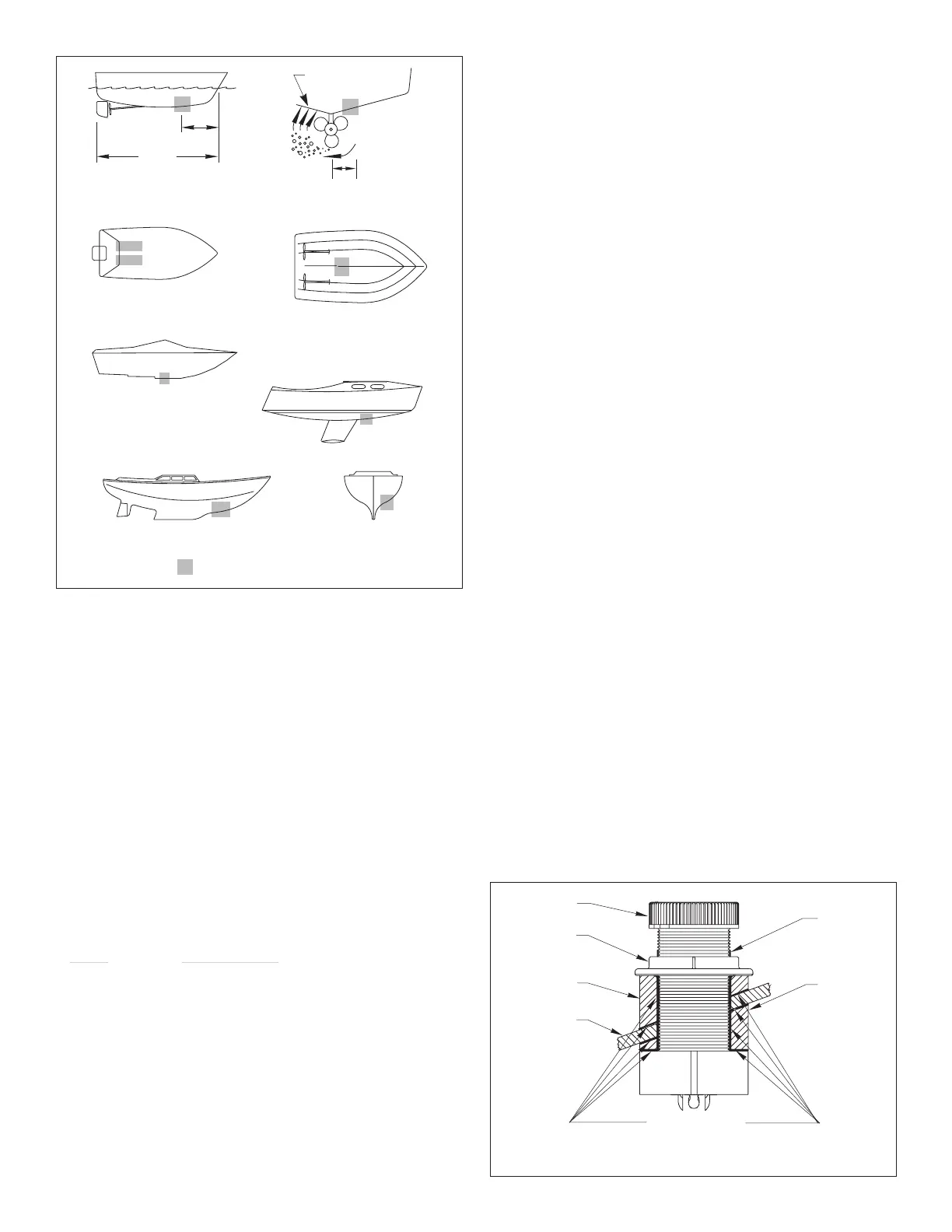

Cored Fiberglass Hull

—Follow separate instructions on page 5

Hole Drilling

Warning

: Always wear safety goggles and a dust mask.

1. Drill a 3mm or 1/8" pilot hole perpendicular to the waterline from

inside the hull (see Figure 2). If there is a rib, strut, or other hull

irregularity near the selected mounting location, drill from the

outside.

2. Using the 51mm

or

2" hole saw, cut a hole from outside the hull.

Be sure to hold the drill plumb

, so the hole will be perpendicular

to the water surface.

3. Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there is

any petroleum residue inside the hull, remove it with either mild

household detergent or a weak solvent (alcohol) before sanding.

2

Figure 1.

Best location for the multisensor

inboard

pressure waves

1/3 aft

full keel sailboat

displacement hull

(6–12")

fin keel sailboat

150–300mm

LWL

(Load Waterline Length)

stepped hull

outboard and I/O

planing hulls

Copyright © 2005 Airmar Technology Corp.

marine sealant

stem

hull nut

backing

hull

Standard

Figure 2. Drilling and bedding

(B744V shown)

cap nut

block

Copyright © 2005 Airmar Technology Corp.

Fairing

Loading...

Loading...