x

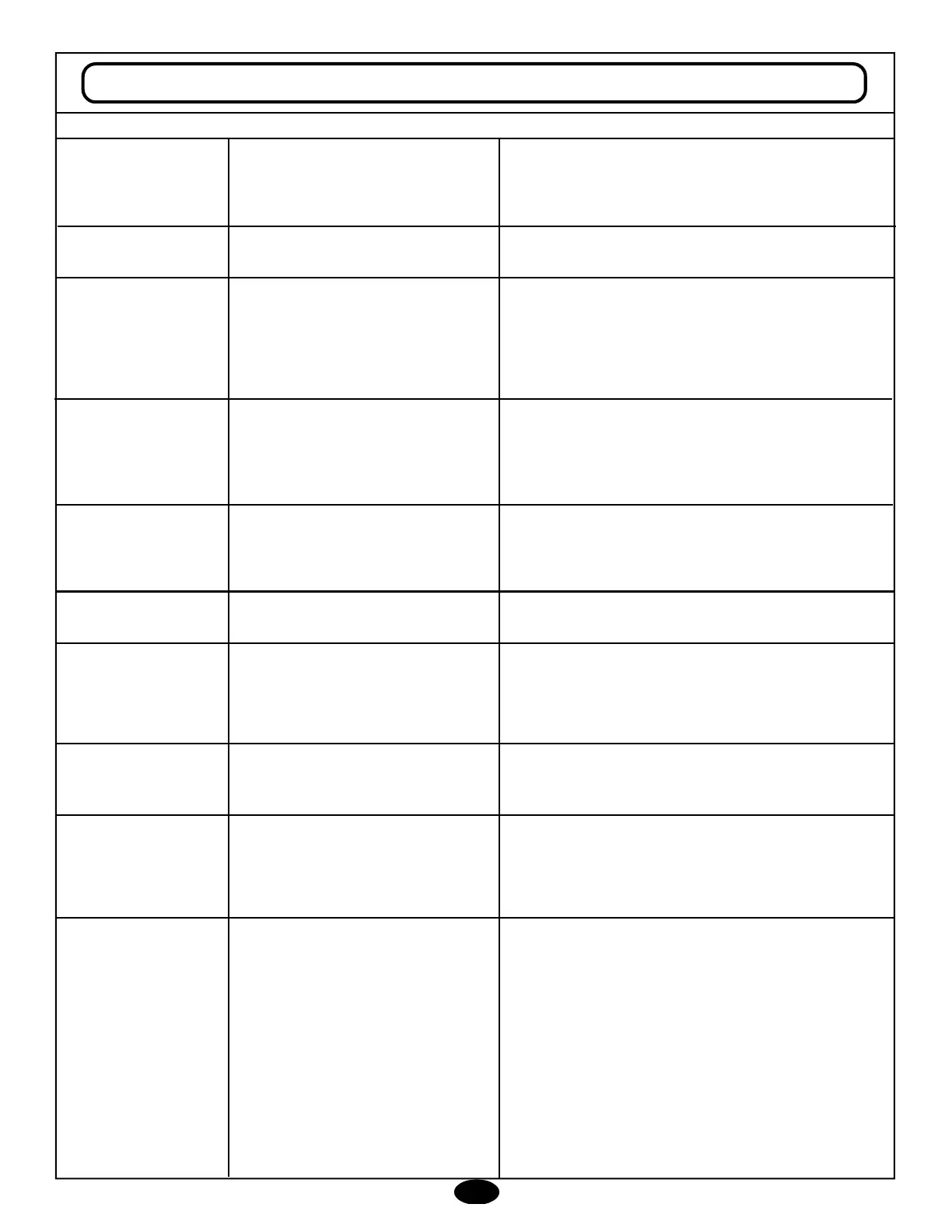

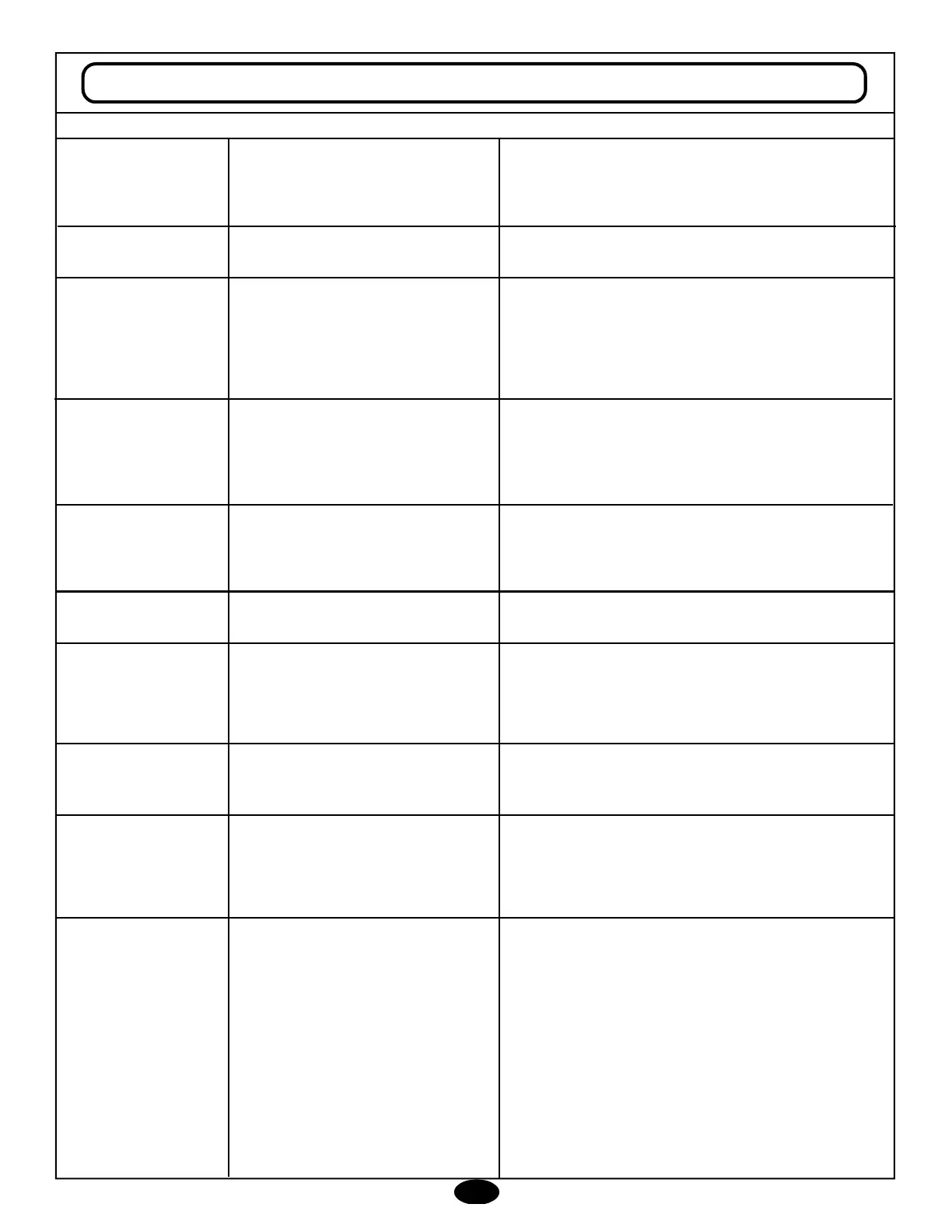

Supersedes 08-27-04 Z08-00195 05-26-06 Z08- 00195

REMEDYPOSSIBLE CAUSE

TROUBLE

1. Oil leaking in the

area of water pump

crankshaft

2. Excessive play on

crankshaft

3. Oil leaking at the

rear portion of the

crankshaft.

4. Water in crankcase

5. Worn bearing

6. Dirty or worn check

valves.

7. Presence of metal

particles during oil

change.

8. Water leakage from

under head.

9. Loud knocking noise

in pump

10.Frequent or

premature failure

of the packing

A. Worn crankshaft seal

B. Bad bearing

C. Grooved shaft

D. Failure of retainer o-ring

A. Defective bearings

B. Excess shims

A. Damaged or improperly installed

oil gauge window gasket.

B. Damaged or improperly installed

rear cover.

C. Oil gauge loosed

D. Rear cover screws loose

A. May be caused by humid air

condensing into water inside the

crankcase.

B. Worn or damaged plunger screw

o-ring.

A. Excessive belt tension.

B. Oil contamination.

A. Normal wear.

B. Debris

A. Failure of internal component.

B. New pump

A. Worn packing

B. Cracked/scored plunger

C. Failure of plunger retainer o-ring

A. Pulley loose on crankshaft

B. Defective bearing

C. Worn connecting rod

D. Worn crankshaft

E. Worn crosshead

A. Scored, damaged, or worn

plunger

B. Overpressure to inlet manifold

C. Abrasive material in the fluid

being pumped

D. Excessive pressure and or

temperature of fluid being

pumped.

E. Over pressure of pumps

F. Running pump dry

A. Remove and replace

B. Remove and replace

C. Remove and replace

D. Remove and replace

A. See “Worn bearing”

B. Set up crankshaft.

A. Replace gasket or o-ring

B. Replace gasket or o-ring

C. Tighten oil gauge

D. Tighten rear cover screws

A. Maintain or step up lubrication schedule

B. Remove and replace. See PLUNGER

SERVICE in PUMP MAINTENANCE

A. See BELT TENSION in MACHINE

MAINTENANCE

B. Check oil type and change intervals per PUMP

SPECIFICATIONS

A. Remove and replace

B. Check for lack of water inlet screens

A. Remove and disassemble to find probable

cause.

B. New pumps have machine fillings and debris

and should be drained and refilled per PUMP

SPECIFICATIONS

A. Install new packing.

B. Remove and replace plunger

C. Remove and replace plunger retainer o-ring

A. Check key and tighten set screw

B. Remove and replace bearing

C. Remove and replace connecting rod

D. Remove and replace crankshaft

E. Remove and replace crosshead

A. Remove and replace plungers

B. Reduce inlet pressure

C. Install proper filtration on pump inlet pumping

D. Check pressures and fluid inlet temperature;

be sure they are within specified range

E. Reduce pressure

F. Do not run pump without water.

PUMP TROUBLESHOOTING

Loading...

Loading...