x

05-26-06 Z08-00062A

Supersedes 08-05-03 Z08-00062A

BURNER NOZZLE REPLACEMENT

1. Using the Fuel Nozzle wrench handle, place outer

part of wrench over nozzle adapter and inner part of

the wrench over the nozzle.

2. Turn the outer handle counter clockwise while holding

the inner handle and remove the nozzle.

3. To reinstall reverse operation and tighten to “squeaky

tight”.

3. Partially close the transformer. Check if the buss

bars contact and are in alignment with transformer

electrodes.

4. Proper adjustment is obtained by gently bending

the buss bars until they spring against, parallel, and

are in full contact with the transformer electrodes.

5. With buss bars aligned, carefully close and fasten

the transformer.

1. Disconnect the fuel line from the burner gun

assembly oil line fitting. Loosen the other end of

the line and swing line out of the way.

2. Remove the retaining nut.

3. Loosen screw and swing transformer away from

burner gun assembly.

4. Carefully remove the burner gun assembly.

A. Check and replace electrode insulators if cracked.

B. Clean burnt buss bars.

C. Clean carbon off electrodes.

D. Clean carbon off oil nozzle. (Use caution not to

scratch face of nozzle or orifice.)

E. Check for a loose oil nozzle.

NOTE: Check with dealer and/or replace nozzle

with proper nozzle.

5. Gently replace burner gun assembly in air tube.

CAUTION: Do not force. Forcing will cause electrode

misalignment

6. Reinstall the retaining nut.

Reinstall the oil line making sure both ends are tight.

7. Partially close transformer. Check if buss bars align

and contact the transformer electrodes. If buss bars

do not contact, see Buss Bar Alignment.

8. Close transformer, reposition retainer and tighten

screw.

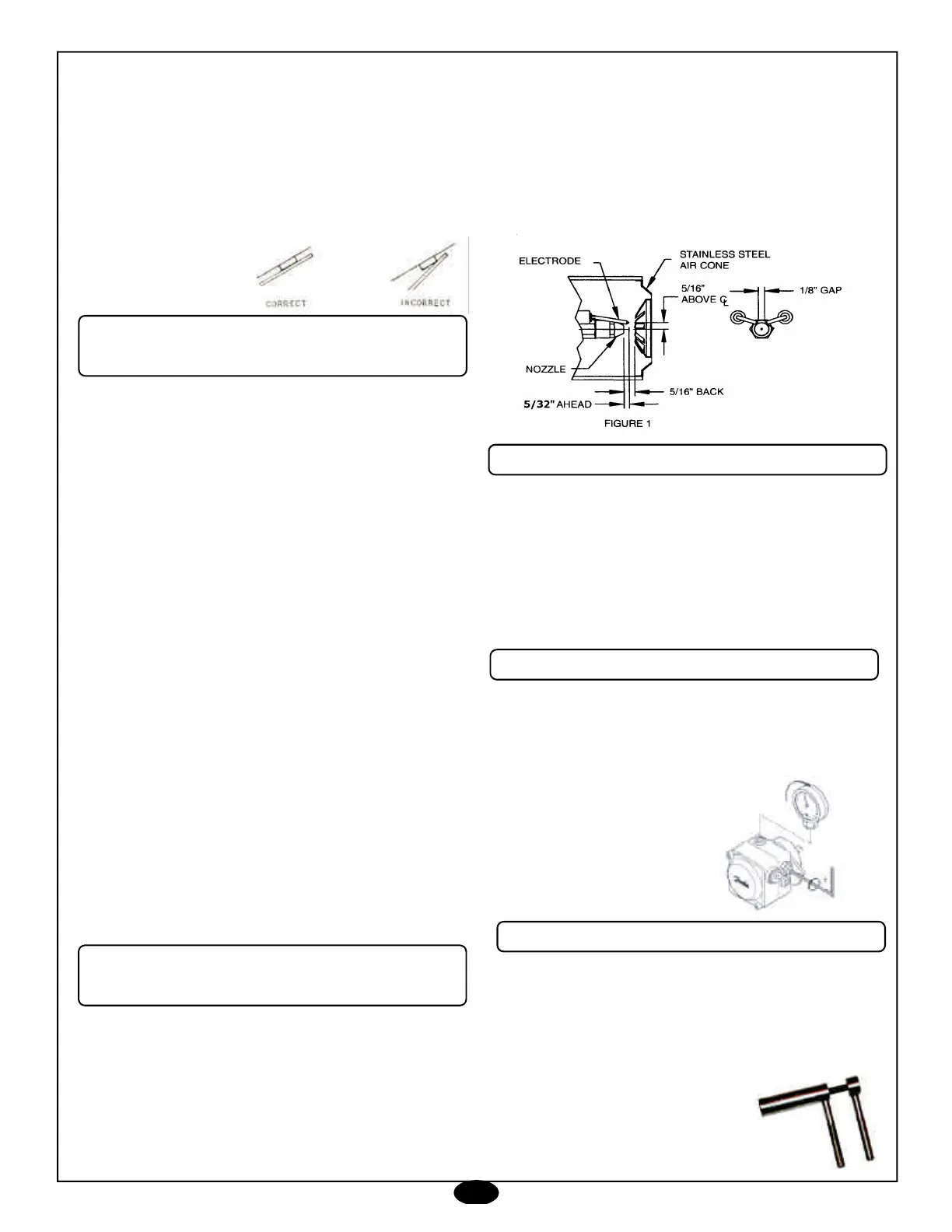

1. Loosen screws holding electrode assemblies.

2. Raise electrode tips 5/32 inches above surface plane

or end of oil nozzle.

3. Place each electrode tip 5/16 inches from center of

spray nozzle hole, maintaining previous

measurement.

BURNER GUN REMOVAL

& INSTALLATION

4. Spread electrode tips to 1/8-inch gap maintaining

previous measurements.

5. When the proper measurements are obtained, gently

tighten screws that hold electrode assembly in place.

CAUTION: Do not over tighten, as this will cause

the electrode insulator to fail.

ASSESSORIES

Z01-00095

1. Remove Plug on top of the fuel pump.

2. Install a 0-200 PSI Pressure Gauge.

3. Insert a 1/8" Allen Wrench and turn clockwise to

increase pressure and

counter clockwise to

decrease.

4. Remove Gauge and

reinstall plug.

FUEL PRESSURE ADJUSTMENT

ZO1-00090 - Allen Wrench 1/8” #8.

Z01- 00095 -Fuel Nozzle Changing Wrench

Z01-00092 -Fuel Pump Wrench (Sundstrand)

Y01-00041-Gauge-0- 200 PSI

Z09-00004 - Bacharach Smoke Tester

ELECTRODE ASSEMBLY

ADJUSTMENT

Loading...

Loading...