Process PI Loop 2-145

may become enabled as soon as the drive goes into run. If analog

input signal loss is detected, the PI loop is disabled.

• PI Hold - The Process PI Controller has the option to hold the

integrator at the current value so if some part of the process is in limit

the integrator will maintain the present value to avoid windup in the

integrator.

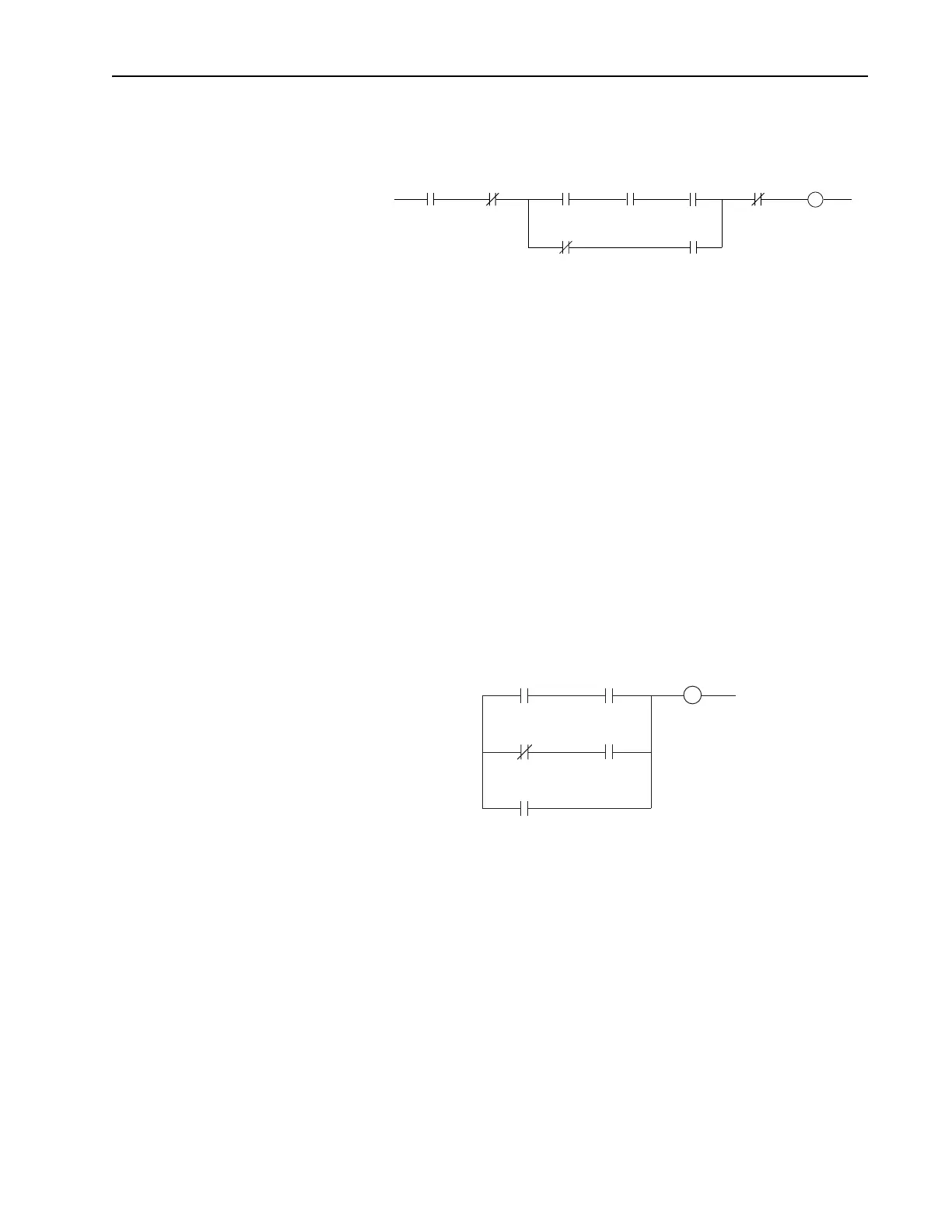

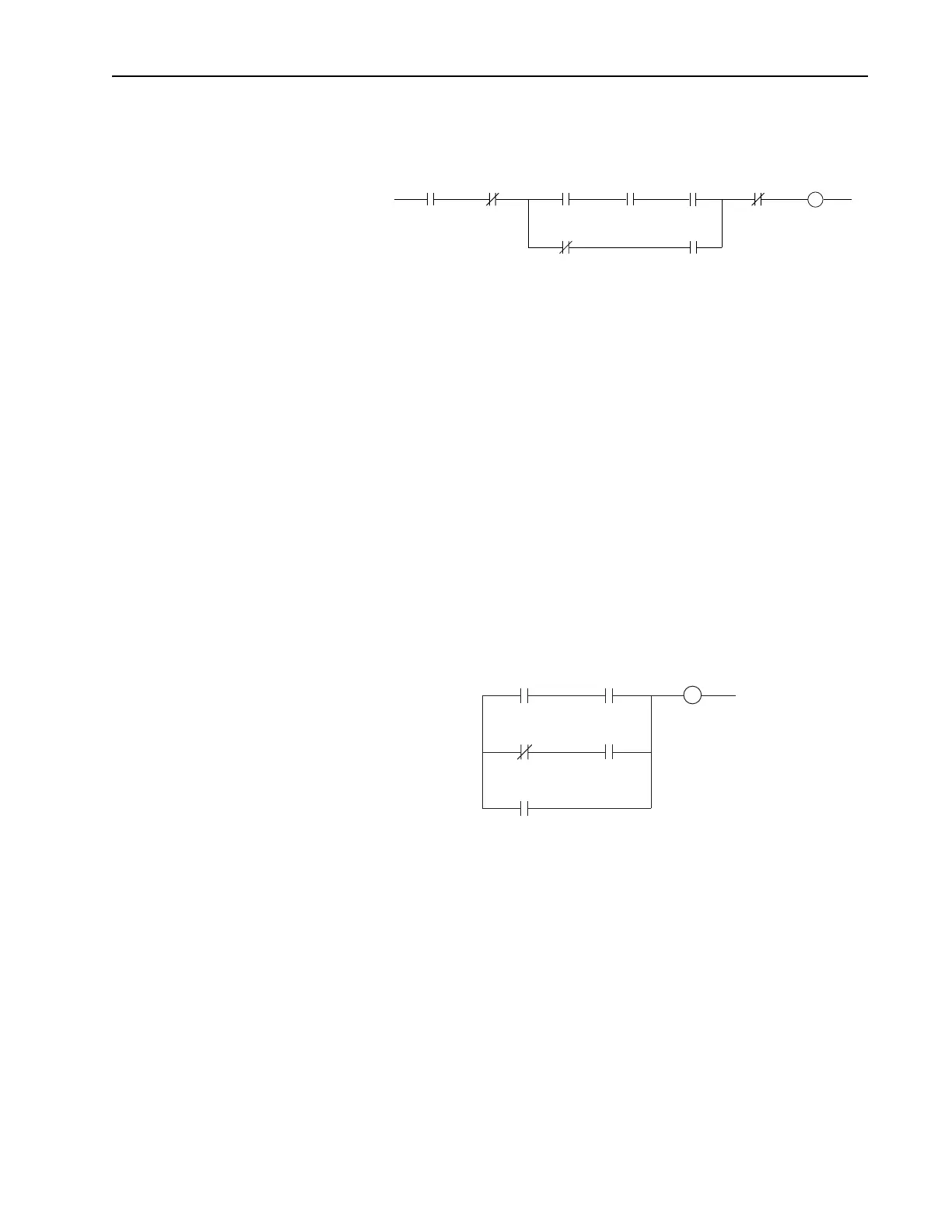

The logic to hold the integrator at the current value is shown in the

following ladder diagram. There are three conditions under which

hold will turn on.

– If a digital input is configured to provide PI Hold and that digital

input is turned on then the PI integrator will stop changing. Note that

when a digital input is configured to provide PI Hold that takes

precedence over the PI Control parameter.

– If a digital input is not configured to provide PI Hold and the PI Hold

bit in the PI Control parameter is turned on then the PI integrator will

stop changing.

– If the current limit or voltage limit is active then the PI is put into

hold.

• PI Reset – This feature holds the output of the integral function at

zero. The term “anti windup” is often applied to similar features. It

may be used for integrator preloading during transfer and can be used

to hold the integrator at zero during “manual mode”. Take the

example of a process whose feedback signal is below the reference

point, creating error. The drive will increase its output frequency in an

attempt to bring the process into control. If, however, the increase in

drive output does not zero the error, additional increases in output will

be commanded. When the drive reaches programmed Maximum

Frequency, it is possible that a significant amount of integral value

has been “built up” (windup). This may cause undesirable and sudden

operation if the system were switched to manual operation and back.

Resetting the integrator eliminates this windup.

Stopping

PI_Status

.Enabled

DigInCfg

.PI_Enable

DigInCfg

.PI_Enable

DigIn

.PI_Enable

PI_Control

.PI_Enable

PI_Control

.PI_Enable

Signal LossRunning

PI_Status

.Hold

DigInCfg

.PI_Hold

DigInCfg

.PI_Hold

DigIn

.PI_Hold

PI_Control

.PI_Hold

Current Lmt

or Volt Lmt

Loading...

Loading...