2-144 Process PI Loop

to operate during the decel ramp until the PI output becomes more

than the master reference. When set to “0,” the drive will disable PI

and perform a normal stop. This bit is active in Trim mode only.

• Anti-Wind Up (PowerFlex 700 Only). When Anti-Windup is set to

“1” the PI loop will automatically prevent the integrator from creating

an excessive error that could cause loop instability. The integrator will

be automatically controlled without the need for PI Reset or PI Hold

inputs.

• Torque Trim. When Torque Trim is set to “1” the output

of the process PI loop will be added to Torque Reference A and B,

instead of being added to the speed reference.

2. [PI Control] is a set of bits to dynamically enable and disable the

operation of the process PI controller. When this parameter is

interactively written to from a network it must be done through a data

link so the values are not written to EEprom.

• PI Enable - The PI loop can be enabled/disabled. The Enabled status

of the PI loop determines when the PI regulator output is part or all of

the commanded speed. The logic evaluated for the PI Enabled status

is shown in the following ladder diagram.

The drive must be in run before the PI Enabled status can turn on. The

PI will remain disabled when the drive is jogged. The PI is disabled

when the drive begins a ramp to stop, except in the PowerFlex 700

when it is in Trim mode and the Stop mode bit in [PI Configuration]

is on.

When a digital input is configured as “PI Enable,” the PI Enable bit of

[PI Control] must be turned on for the PI loop to become enabled.

If a digital input is not configured as “PI Enable” and the PI Enable

bit in [PI Control] is turned on, then the PI loop may become enabled.

If the PI Enable bit of [PI Control] is left continuously, then the PI

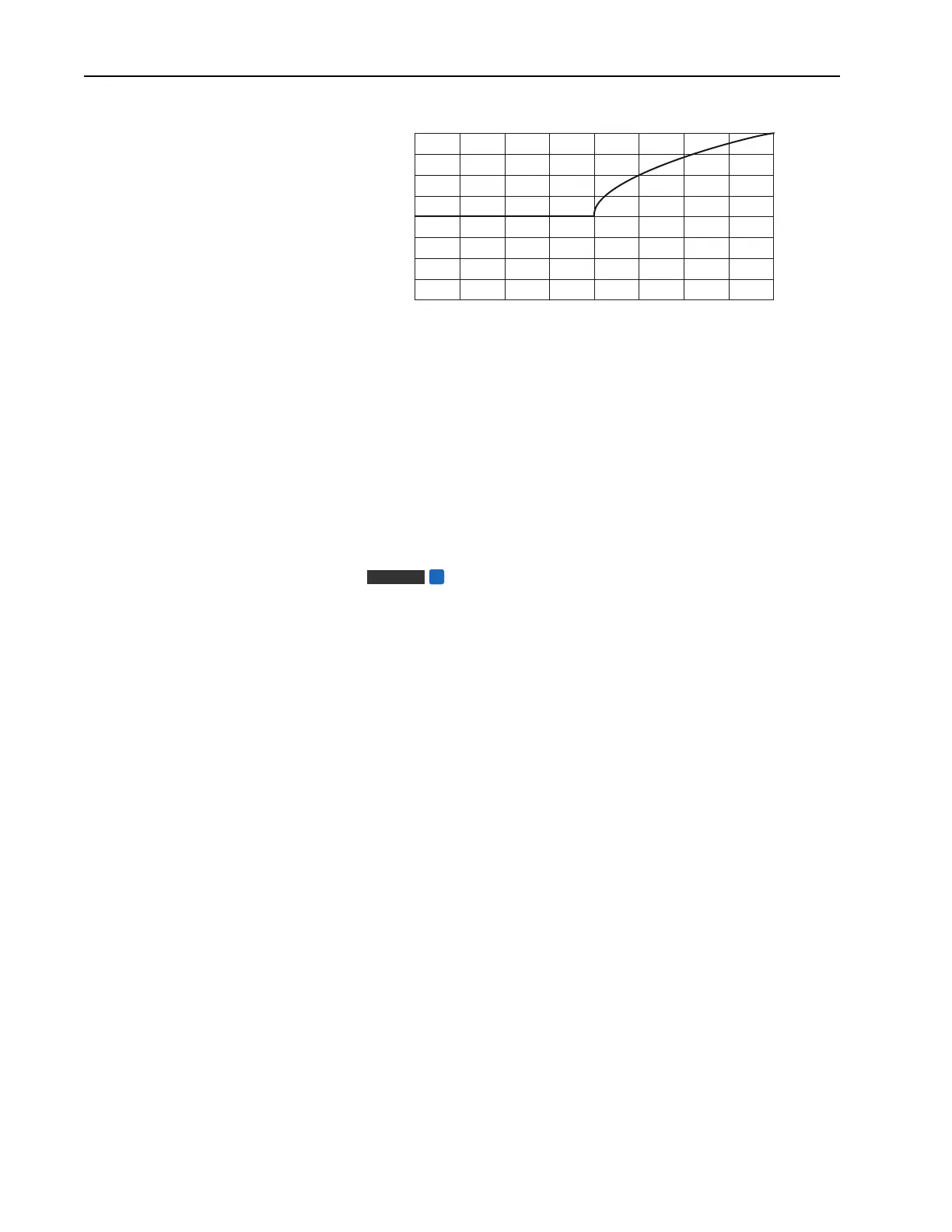

-100.0 -75.0 -50.0 -25.0 0.0 25.0 50.0 75.0 100.0

Normalized Feedback

Normalized SQRT(Feedback)

-100.0

-75.0

-50.0

-25.0

0.0

25.0

50.0

75.0

100.0

Vector

FV

Loading...

Loading...