54 Rockwell Automation Publication 20A-IN009E-EN-P - January 2015

PowerFlex 70 Adjustable Frequency AC Drive

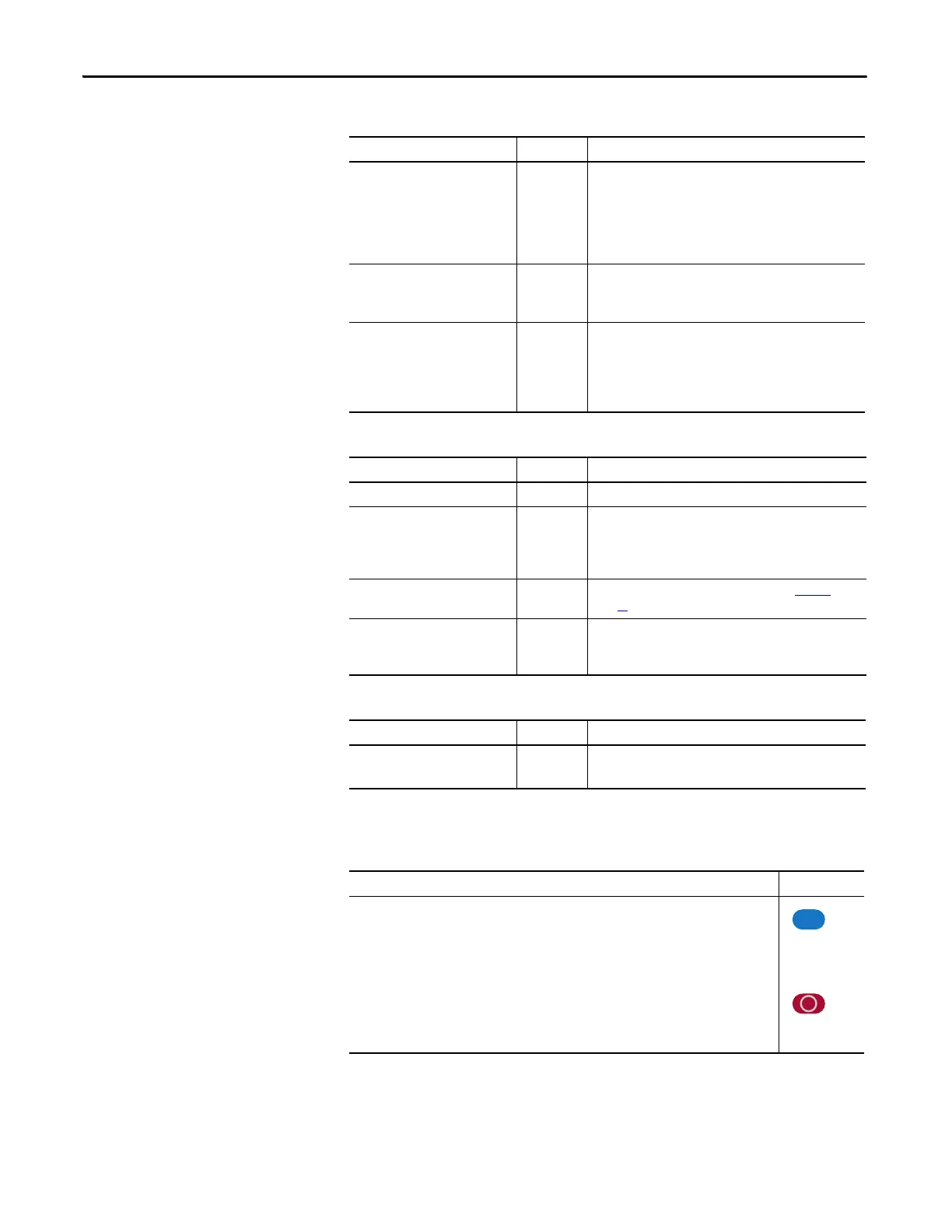

Table 25 - Drive Does Not Respond to Changes in Speed Command

Table 26 - Motor and/or Drive does Not Accelerate to Commanded Speed

Table 27 - Motor Operation is Unstable

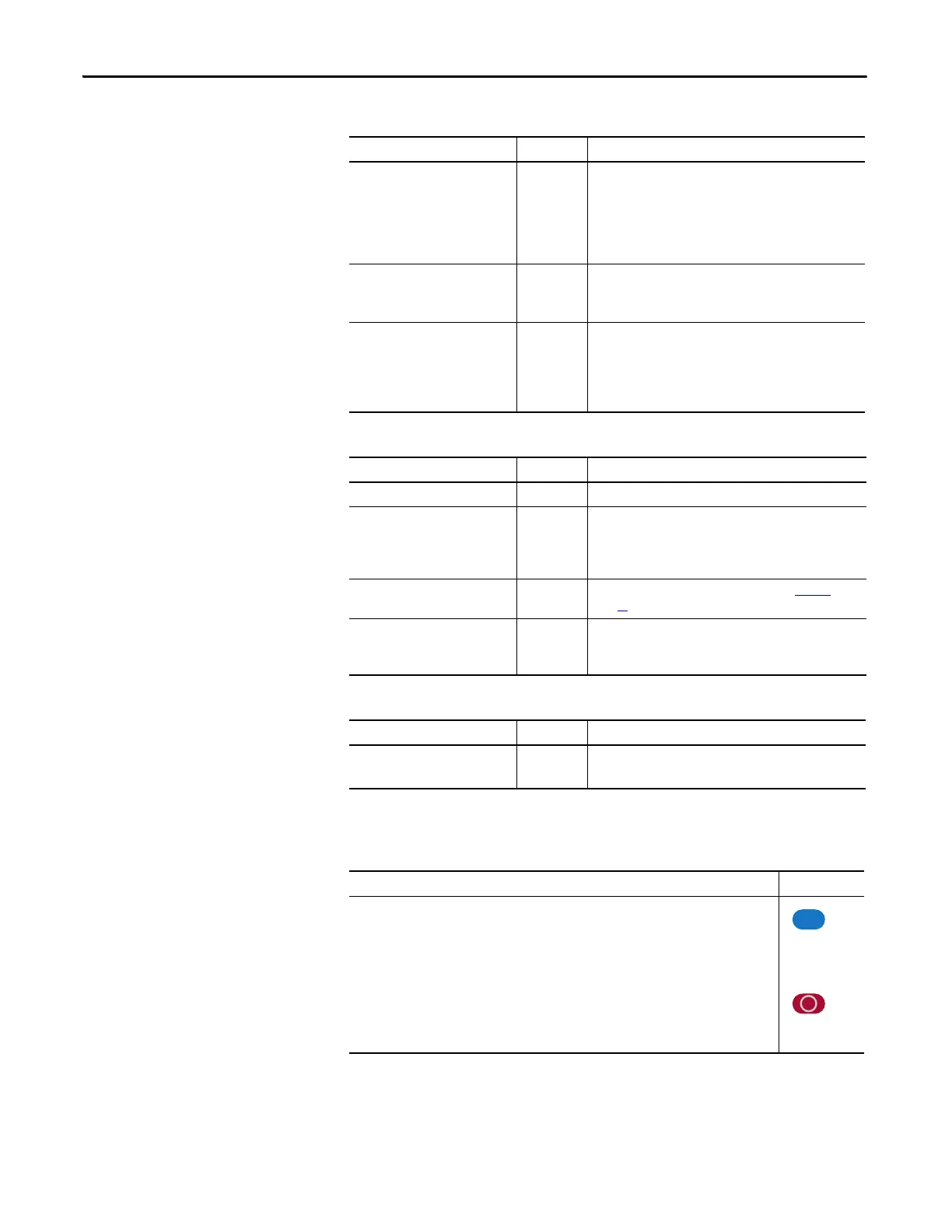

Manually Clearing Faults

Cause Indication Corrective Action

No value is coming from the source

of the command.

LCD HIM

Status Line

indicates “At

Speed” and

output is 0

Hz.

1. If the source is an analog input, check wiring and use a

meter to check for presence of signal.

2. Check [Commanded Freq] for correct source.

Incorrect reference source has been

programmed.

None 1. Check [Speed Ref Source] for the source of the speed

reference.

2. Reprogram [Speed Ref A Sel] for correct source.

Incorrect reference source is being

selected via remote device or digital

inputs.

None 1. Check [Drive Status 1], bits 12 and 13 for unexpected

source selections.

2. Check [Dig In Status] to see if inputs are selecting an

alternate source.

3. Reprogram digital inputs to correct “Speed Sel x” option.

Cause Indication Corrective Action

Acceleration time is excessive. None Reprogram [Accel Time x].

Excess load or short acceleration

times force the drive into current

limit, slowing or stopping

acceleration.

None Check [Drive Status 2], bit 10 to see if the drive is in Current

Limit.

Remove excess load or reprogram [Accel Time x].

Speed command source or value is

not as expected.

None Check for the proper Speed Command by using Table 25

on

page 54

.

Programming is preventing the

drive output from exceeding

limiting values.

None Check [Maximum Speed] and [Maximum Freq] to assure that

speed is not limited by programming.

Cause Indication Corrective Action

Motor data was incorrectly entered

or Autotune was not performed.

None 1. Correctly enter motor nameplate data.

2. Perform “Static” or “Rotate” Autotune procedure.

Step Key(s)

1. Press Esc to acknowledge the fault.

The fault information is removed so that you can use the Human Interface Module (HIM).

2. Address the condition that caused the fault.

The cause must be corrected before the fault can be cleared.

3. After corrective action has been taken, clear the fault by one of these methods:

• Press Stop.

• Cycle drive power.

• Set parameter 240 [Fault Clear] to “1”.

• “Clear Faults” on the Human Interface Module (HIM) Diagnostic menu.

Loading...

Loading...