Rockwell Automation Publication 20A-IN009E-EN-P - January 2015 35

PowerFlex 70 Adjustable Frequency AC Drive

Step 4: I/O Wiring

Important points to remember about I/O wiring:

• Use copper wire. Wire gauge requirements and recommendations are

based on 75 °C (167 °F). Do not reduce wire gauge when you are using

higher temperature wire.

• Wire with an insulation rating of 600V or greater.

• Control and signal wires must be separated from power wires by at least

0.3 m (1 ft).

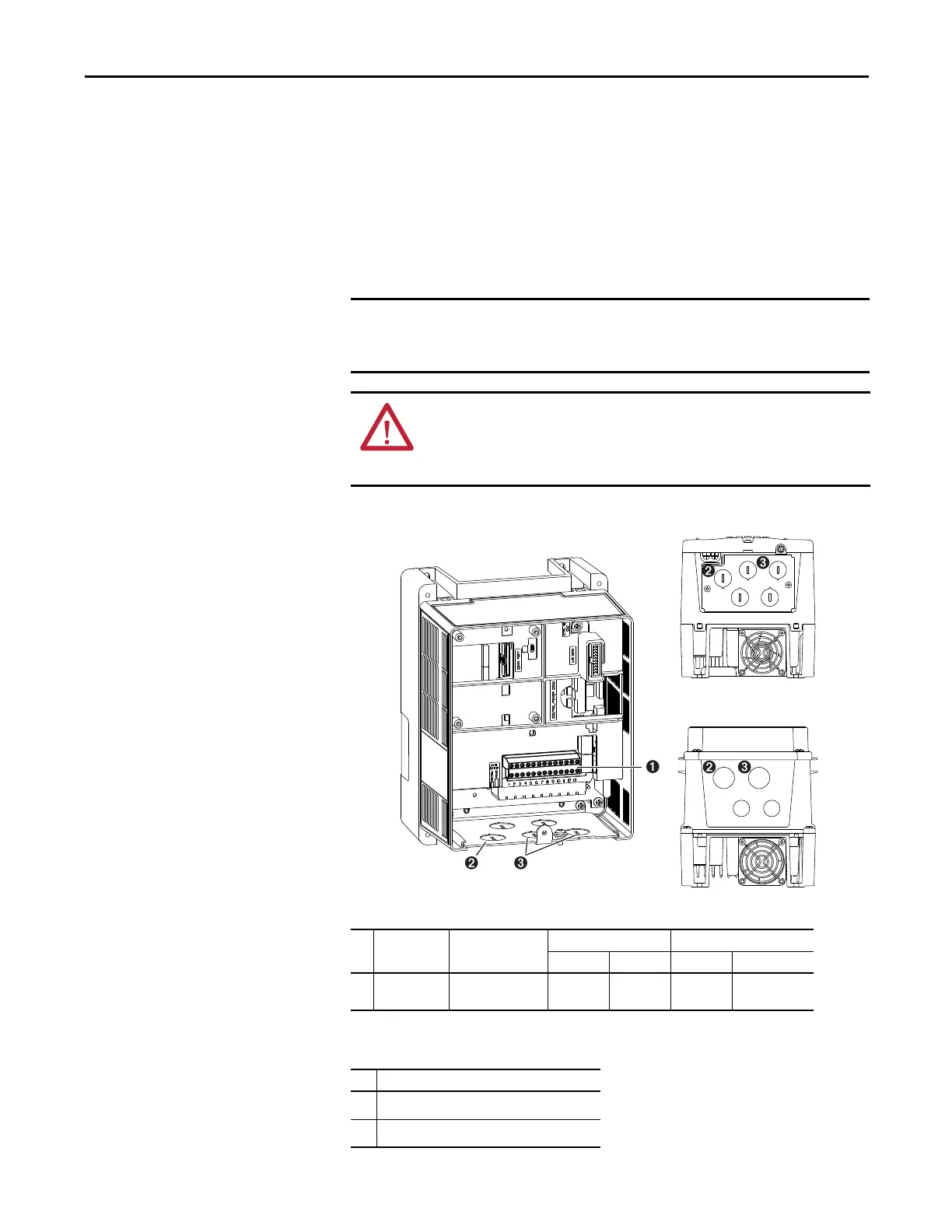

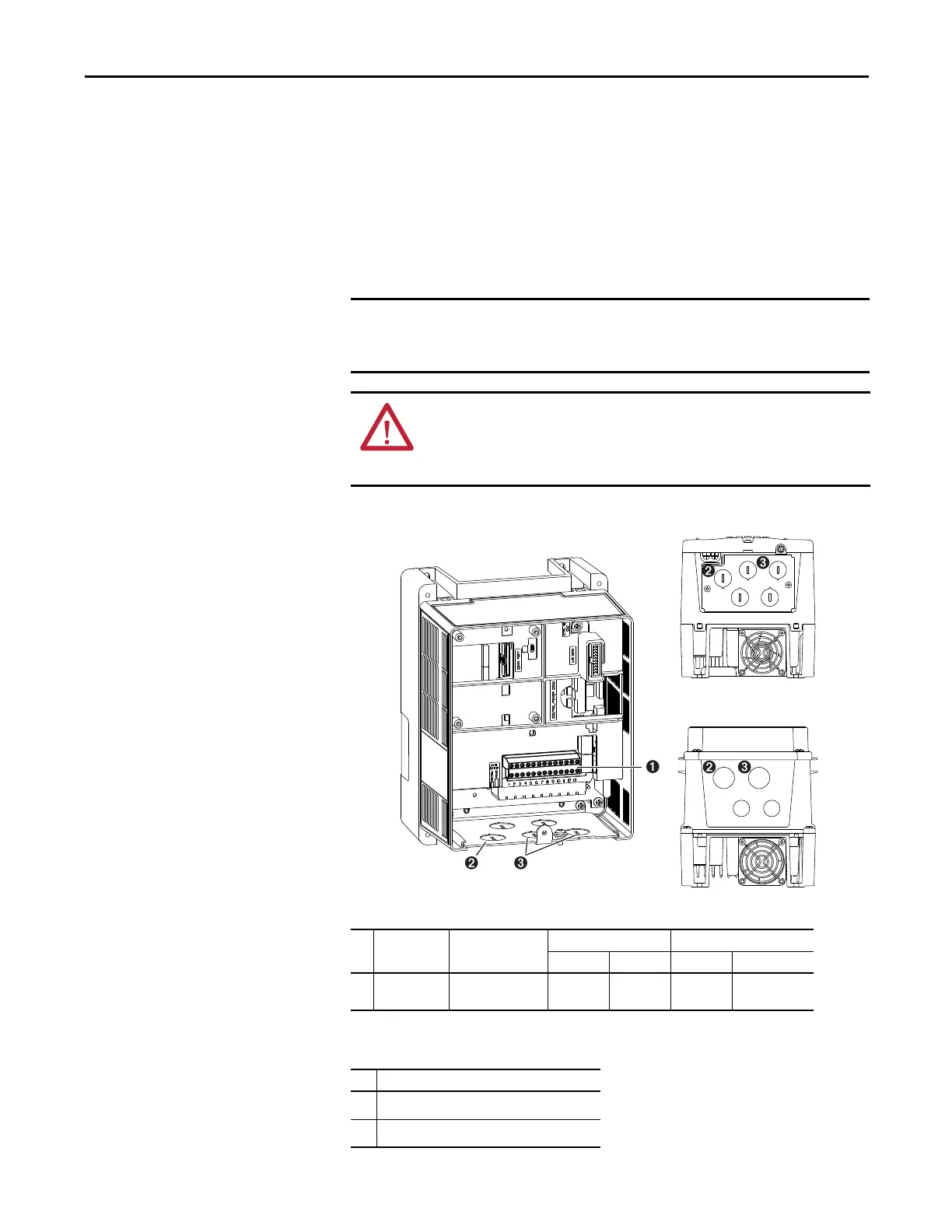

Figure 13 - Typical I/O Terminal Block Location (B Frame Shown)

Table 15 - I/O Terminal Block Specifications

Table 16 - Wire Routing Recommendations

I/O terminals that are labeled “(–)” Digital In Common or “Common” are not

connected to earth ground and are designed to greatly reduce common mode

interference. Grounding these terminals can cause signal noise.

ATTENTION: Hazard of personal injury or equipment damage exists when

using bipolar input sources. Noise and drift in sensitive input circuits can cause

unpredictable changes in motor speed and direction. Use speed command

parameters to help reduce input source sensitivity.

No. Name Description

Wire Size Range

(1)

(1) Maximum / minimum that the terminal block can accept - these are not recommendations.

Torque

Max Min Max Recommended

➊

I/O terminal

block

Signal and control

connections

1.5 mm

2

(16 AWG)

0.05 mm

2

(30 AWG)

0.55 N•m

(4.9 lb•in)

0.5 N•m

(4.4 lb•in)

No. Description

➋

Suggested entry for communication wiring.

➌

Suggested entry for I/O and control wiring.

Loading...

Loading...