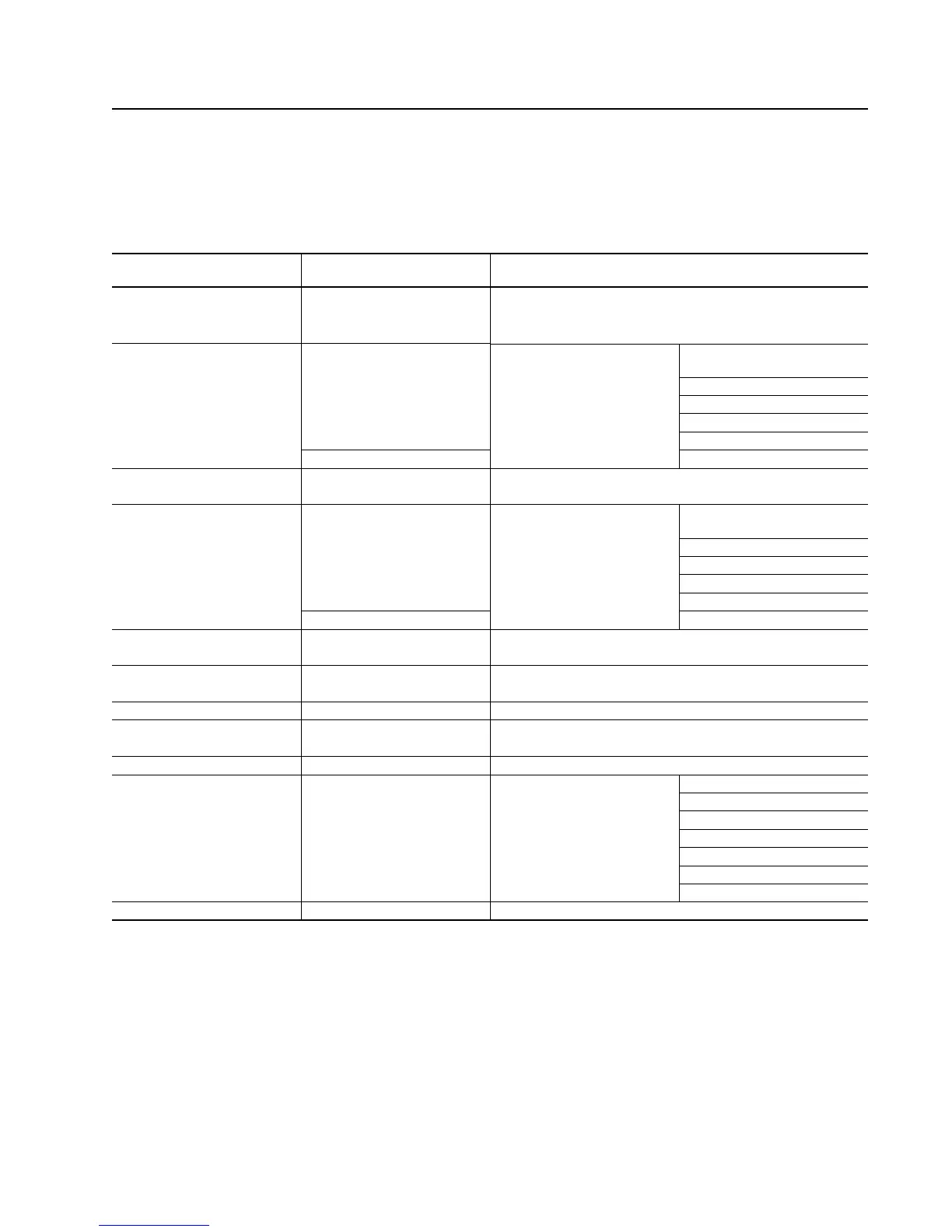

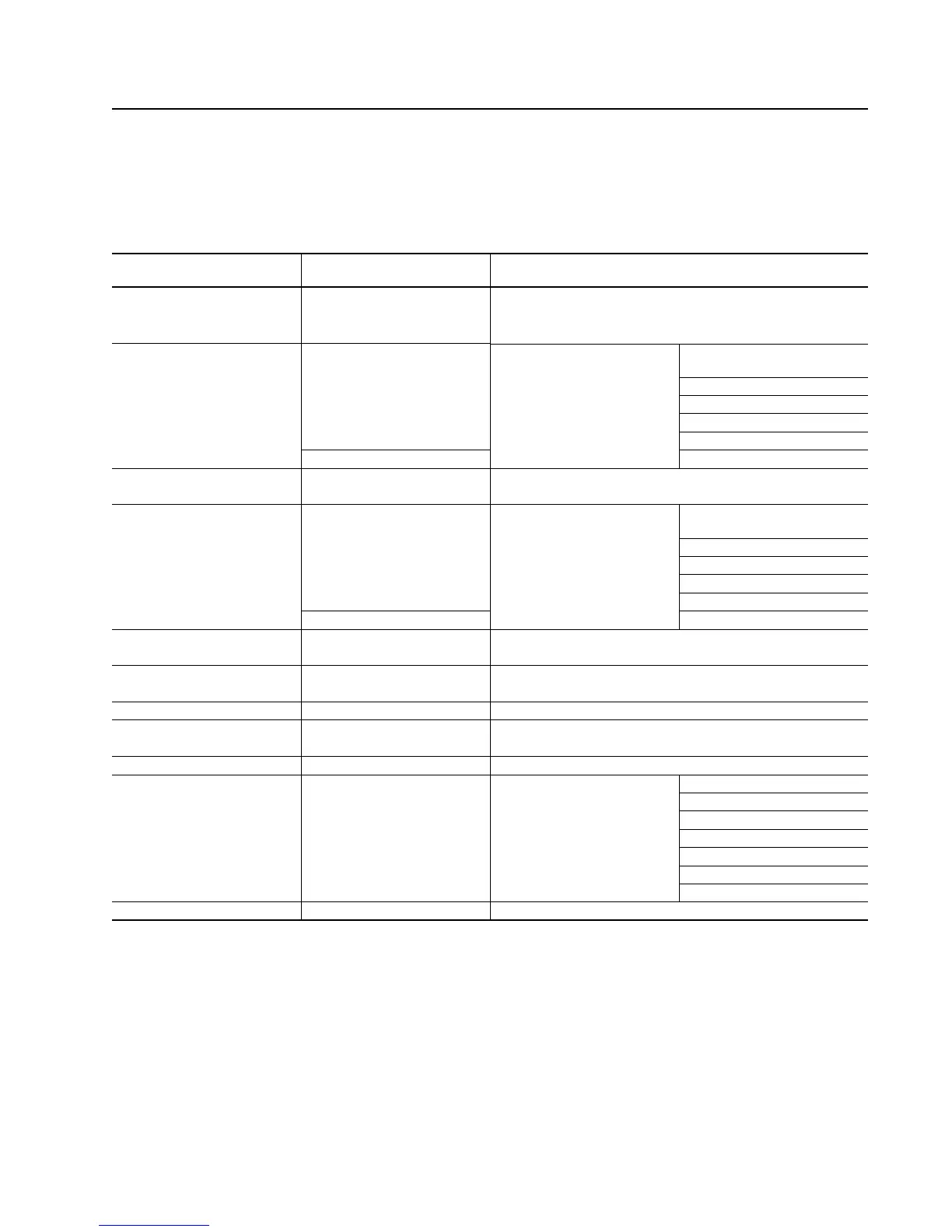

Chapter 3

Motor Control Center Vertical Sections

Features and Modifications

Table 3.A Motor Control Center Vertical Section Features and Modifications

1 All 1336 D and E-frame drive units and common DC bus F-frame drive units and PowerFlex frames 4 - 9 have 20" deep sections as standard. Common AC bus F-frame drive units and all

G-frame and H-frame drive units have 25"bump-back sections as standard.

2 If you are using a Bulletin 2364 front-end common-DC-bus supply unit in your lineup, verify that the front-end depth is compatible with the Bulletin 2362 sections that you are selecting.

3 If ANY one section is at least 20" deep, then ALL sections in that lineup must be at least 20" deep.

4 You must specify a power bus and a ground bus for each section.

5 3000A-rated horizontal power bus requires a 1/4" x 2" horizontal ground bus (PE) selection. Zero potential bus (TE) remains at 1/4" x 1" regardless of horizontal ground bus (PE) size selection.

Splice kits with 1/4" x 2" PE contain three 1/4" x 1" bus splices (Qty 2 for PE + Qty 1 for TE); splice kits with 1/4" x 1" PE contain two.

6 One kit required per shipping split on flush-front lineups. (Control bus splice kits are only required if lineup has control bus.)

7 Common AC bus F-frame drive units and all G-frame and H-frame drive units require base channels.

8 If you are using a Bulletin 2364 front-end unit in your lineup, lookup the base channel requirements of the front-end being utilized.

9 If ANY one section has base channels, then ALL sections in that lineup must have this optional base channel factory-installed. Base channels add 1.5" to the overall section height.

10 PowerFlex® frame 10 requires a 25” deep flush back section.

Section Features and

Modifications App. Notes Description

Section 1, 2, 3, 10 15” Deep

Depth 20” Deep

25” Deep (flush back)

Horizontal

Power Bus

4 Tin-plated copper busbar Bus

Rating

800A

1200A (AC only)

1600A

2000A

4, 5 3000A

Horizontal Power 42kAIC (rms Symmetrical)

Bus Bracing 65kAIC (rms Symmetrical)

Horizontal

Power Bus

Splice Kit

6 Splice bars and assembly

hardware.

Bus

Rating

800A

1200A

1600A

2000A

5, 6 3000A

Horizontal (PE / TE) 4, 5 1/4” x 1” PE and 1/4” x 1” TE tin-plated copper bus

Ground Bus 1/4” x 2” PE and 1/4” x 1” TE tin-plated copper bus

Horizontal Ground 5, 6 For 1/4” x 1” PE and 1/4” x 1” TE tin-plated copper bus

Bus Splice Kit For 1/4” x 2” PE and 1/4” x 1” TE tin-plated copper bus

Horizontal Control Bus Tin-plated copper 115V AC control bus rated at 90A

Horizontal Control Bus 6 For tin-plated copper 115V AC control bus rated at 90A

Splice Kit

Pull Box 12” High x 15” Deep, 20” Deep OR 25” Deep

Blank Unit Doors Covers unused unit space (includes

unit support pan)

0.5 SF

1.0 SF

1.5 SF

2.0 SF

2.5 SF

3.5 SF

4.5 SF

Base Channels 7, 8, 9 Two 1.5” x 3” mounting channels (One front, one rear)

Loading...

Loading...