508433-01Issue 2345Page 20 of 70

Switch 5 -- Cooling Mode Blower-O Delay -- The unit

is shipped from the factory with the dip switch positioned

OFF for a 45 second delay. Table 6 provides the cooling

mode o delay settings.

Blower O Delay

(seconds)

Switch 5

45 (Factory) O

2 On

Table 6. Blower O Cooling Mode Delay Switch

Settings

Switches 6 and 7 -- Continuous Fan Mode -- Continuous

fan speed can be controlled by changing DIP switch

positions. Table 7 provides DIP switch settings for

continuous fan mode.

Continuous Fan

Mode

Switch 6 Switch 7

Low Heat Speed

(Factory)

O O

Low Cool Speed O On

High Heat Speed On O

High Cool Speed On On

Table 7. Continuous Fan Mode Settings

Onboard Links

W914 Dehum

Onboard link W914, is a clippable connection between

terminals R and DS on the integrated control. W914 must

be cut when the furnace is installed with a thermostat which

features humidity control. If the link is not cut, terminal “DS”

will remain energized not allowing the blower to reduce to

low cool speed upon a call for dehumidication.

W951 Heat Pump (R to O)

Onboard link W951 is a clippable connection between

terminals R and O on the integrated control. W951 must

be cut when the furnace is installed in applications which

include a heat pump unit and a thermostat which features

dual fuel use. If the link is left intact, terminal “O” will remain

energized eliminating the HEAT MODE in the heat pump.

W915 2 Stage Compr (Y1 to Y2)

Onboard link W915 is a clippable connection between

terminals Y1 and Y2 on the integrated control. W915 must

be cut if two-stage cooling will be used. If the Y1 to Y2

link is not cut the outdoor unit will operate in second-stage

cooling only.

If any onboard link is cut by mistake, install a jumper

across the corresponding terminals on the low voltage

terminal strip. Do not replace control.

IMPORTANT

Blower Compartment

Each blower is statically and dynamically balanced as

an assembly before installation in the unit.

IMPORTANT

A97UH2E units are equipped with a constant torque ECM

motor. It has a DC motor coupled to an electronic control

module both contained in the same motor housing. The

motor is programmed to provide constant torque at each of

the ve selectable speed taps. Each tap requires 24 volts

to energize.

Input Voltage Requirements

The circuit is designed to be operated with AC voltage. To

enable a tap requires 12 to 33VAC. Expected current draw

will be less than 20mA.

Troubleshooting the Motor

Troubleshooting the motor is an easy process. Follow

steps below.

1. Shut o power to unit.

2. Remove input plugs P48 and P49 from motor. See

Figure 10 for troubleshooting procedure.

If correct voltage is present in tests 1 and 2 and motor is

not operating properly, replace motor. The motor is not eld

repairable.

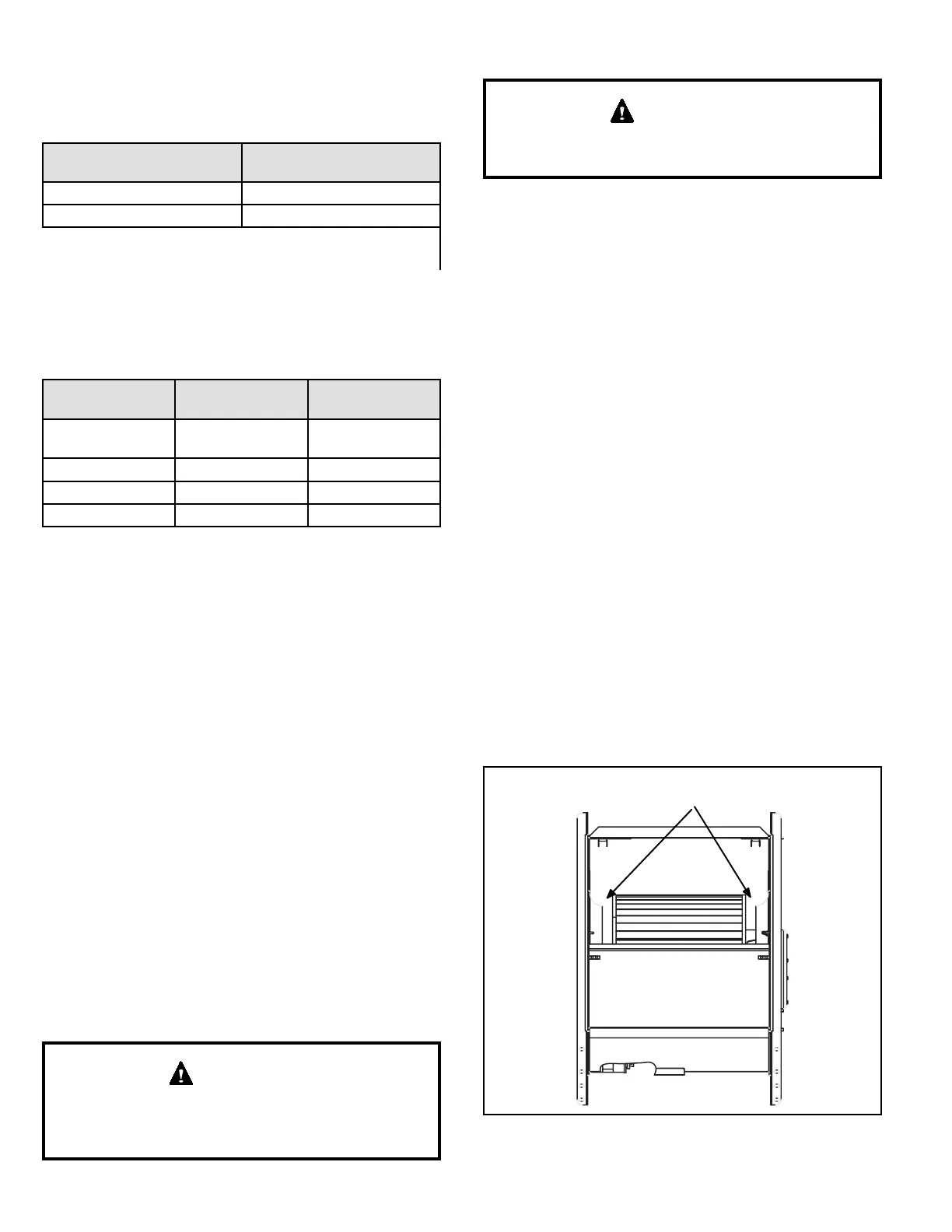

If replacing the indoor blower motor or blower wheel is

necessary, placement is critical. The blower wheel must

be centered in the blower housing as shown in Figure 6.

When replacing the indoor blower motor the set screw

must be aligned and tightened with the motor shaft as

shown in Figure 7.

Figure 6. Blower Wheel Replacement

Center Blower Wheel

in Blower Housing

Loading...

Loading...