5

OPERATIONINEXPLOSION‐PROOFAREASANDFORFLAMMABLELIQUIDS(REG.‐NO.PTB:03ATEXD004)

For flammable liquids as well as for applications in explosion‐proof areas, only pumps

with housingsandfittings in conductiveplastic materialsmaybe used.AODDpumps of

theE‐Serieswiththehousingcodes

F(PEconductive)andU(PTFEconductive)meetthis

requirement. The pump has to be grounded. A connection to ground the pump is

included in the center housing [4]. All other housing parts are connected to the center

housing;thereforeitisnotnecessarytogroundsingleparts.

ALMATECE‐Series

pumpsmadeofelectricallyconductivePE/PTFEaresuitabletobeused

in explosion areas of the category 2 and 3, atmosphere G/D, which are liable to the

94/9/EG. Conductive diaphragms (liquid side) are applicable without restrictions for

transferringliquidsofanyexplosion‐group.

When using non‐conductive diaphragm materials,the

following exemplary protection measures haveto be

respected:

‐Thepumpisalwaysusedforthetransferofexclusivelyfluidswhichareconductiveorsolubleinwateror

‐Dry‐runningisavoidedbyactionstepswithinthefacilityand/oritscontrolor

‐ The system is inertisated in case of dry

running by nitrogen, water, carbon dioxide etc. when the fluid

transferends.

Piping systems and product connections have to be grounded separately. To avoid ignition hazards the

formation of dust deposits on the pumps must be prevented. In explosion proof areas repair working only

aftercarefulinspectionofthepracticability

andonlywithappropriatetools.FortheATEXmarkingaccording

to94/9/EGpleaseseetheattachedconformitydeclarationandtheaccordingpumplabel.

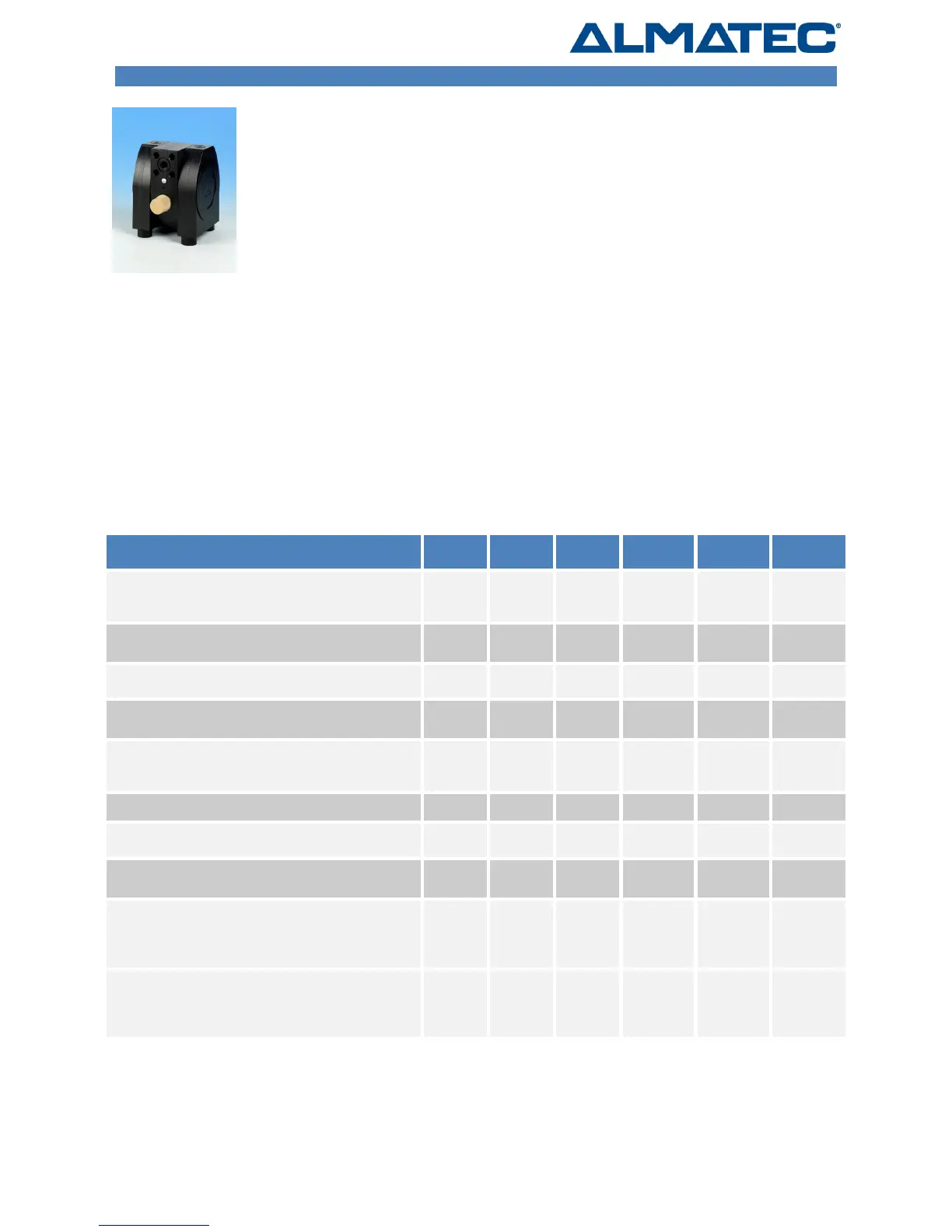

TECHNICALDATA E08 E10 E15 E25 E40 E50

Dimensions,mm(in.): length

width

height

88(3.5)

128(5.0)

129(5.1)

110(4.3)

147(5.8)

169(6.7)

166(6.5)

189(7.4)

240(9.4)

220(8.7)

255(10.0)

320(12.6)

304(12.0)

353(13.9)

432(17.0)

399(15.7)

430(16.9)

552(21.7)

NominalportsizeNPT

AirconnectionBSP

1/4“

R1/8

3/8“

R1/8

1/2“

R1/4

1“

R1/4

11/2“

R1/2

2“

R1/2

Weight,kg(lb):PE

PTFE

‐

2(4)

‐

5(11)

7(15)

12(26)

15(33)

29(64)

34(75)

69(152)

66(146)

131(289)

Max.particlesizeofsolids mm(in.)

forpumpswithballvalves

2(0.08) 3(0.12) 4(0.16) 6(0.24) 9(0.35) 11(0.43)

Suctionliftdry,mWC(ft): cylindervalves

ballvalves

Suctionliftwet,mWC(ft)

1(3.3)

0,4(1.3)

9(29.5)

2(6.6)

1(3.3)

9(29.5)

3(9.8)

2(6.6)

9,5(31.2)

4(13.1)

3(9.8)

9,5(31.2)

5(16.4)

4(13.1)

9,5(31.2)

5(16.4)

4(13.1)

9,5(31.2)

Max.drivingandoperatingpressure,bar(psig) 7(100) 7(100) 7(100) 7(100) 7(100) 7(100)

Max.operatingtemperature,°C(F): PE

PTFE*

‐

100(212)

‐

100(212

70(158)

120(248)

70(158)

120(248)

70(158)

120(248)

70(158)

120(248)

Theoreticaldisplacementvolume

persinglestroke(l)

0,0075 0,0215 0,1 0,34 0,98 2,6

SoundpowerlevelL

WA

[dB(A)]:**

drivingpressure3bar

drivingpressure5bar

drivingpressure7bar

77,5‐84,0

80,0‐86,5

80,2‐87,0

79,5‐81,0

79,5‐85,0

79,5‐86,0

77,0‐89,0

75,0‐94,0

74,0‐96,0

74,0‐84,2

68,6‐87,8

70,0‐91,0

82,2‐86,6

72,2‐95,5

68,5‐94,4

66,6‐84,9

73,5‐91,5

67,3‐96,0

SoundpressurelevelL

pf

,1m[dB(A)]:***

drivingpressure3bar

drivingpressure5bar

drivingpressure7bar

64,1‐70,3

66,2‐73,1

66,8‐73,8

65,9‐67,5

65,7‐70,8

65,7‐72,1

63,2‐74,9

60,9‐80,1

60,3‐82,0

61,7‐71,9

56,3‐75,5

57,7‐78,8

69,5‐73,9

59,5‐82,8

55,8‐81,7

53,4‐71,7

60,3‐78,3

54,1‐82,8

* PTFEpumpswithNBRequipment80°C(176°F)

** determinedinsoundpowerlevelmeasurementsaccordingtoENISO3744respectivelyENISO9614inlaboratoryandpractise

conditions

*** soundpressurelevelsasaveragelocation‐independentvaluescalculatednorm‐conformousfromthelocationofthesound

powerlevelslistedabove

ThesetechnicaldatarefertoALMATECE‐Seriespumpswithoutoptionalequipment.

Loading...

Loading...