The following example uses this configuration:

i) Controller is set up to use a thermistor type sensor (10Kohms @ 25°C) on the 0 to 100K

range (

[`)00] to [9(99]) by following the instruction in Section 4.0 under “Sensor

Programming & Configuration”

ii) The controller being used is a 150 Watt which has a +15V power supply and a Maximum

Current specified at 10 Amperes.

Knowing the controller’s set up information above will allow one to quickly determine

what the controller is doing at any given time by simply analyzing the front panel while

at the Home Page

1

.

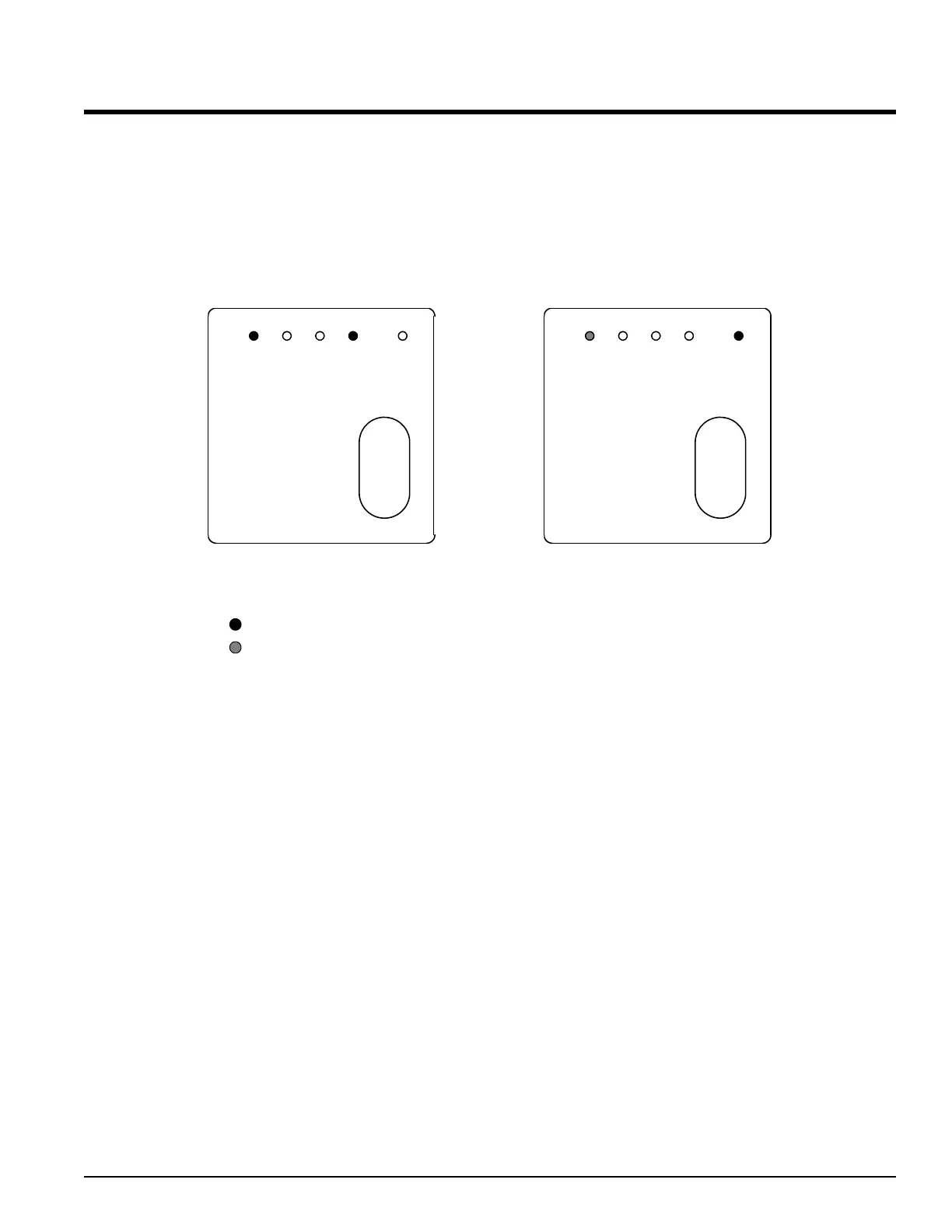

Above are two front panel drawings. Examining the drawing on the left, one can

quickly see that Output 1 is on because the light is on. The Output 1 light always

corresponds to Cooling, therefore the controller should be outputting positive current to

the thermoelectric cooler (TEC).

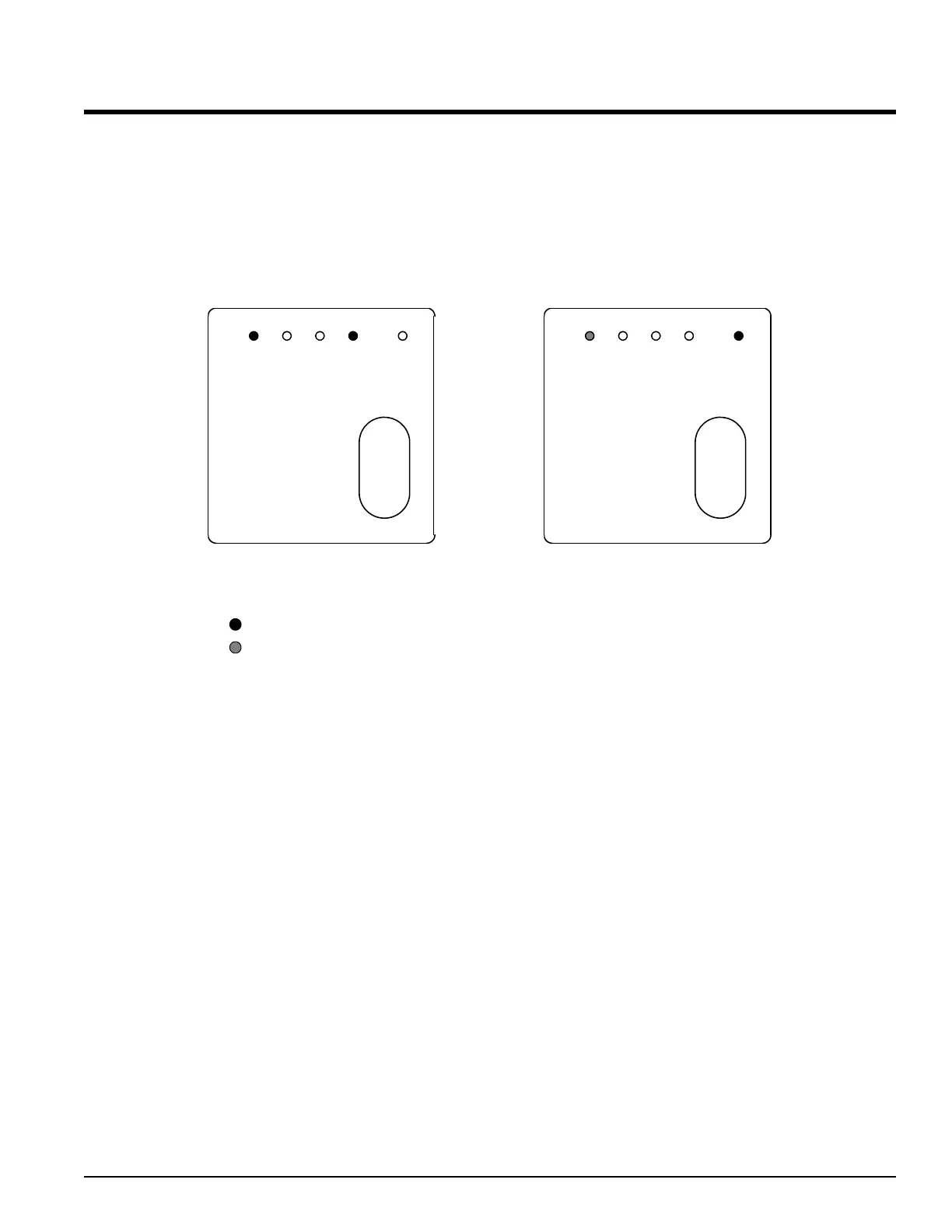

The drawing on the right indicates that the controller is in manual mode since the %

light is ON. Notice how the lower display is at -50%. This indicates the power level

and the polarity. The reason for this is that thermistors are negative temperature

coefficient devices and the negative sign would indicate “Cooling” while a positive

number would indicate “Heating”. All positive temperature coefficient devices will

indicate a positive % output for “Cooling” and a negative % output for “Heating”.

ALPHA OMEGA INSTRUMENTS CORP. Instruction Manual

Series 800/850 Thermoelectric Cooler Controller Page 66

¿

[3)59]

[4%00}

1234

Home

‰¯ˆ

%

¿

[2@87]

[-5)0}

1234

Home

‰¯ˆ

%

ON STEADY = 100% CURRENT

50% DUTY CYCLE = 50% CURRENT

LIGHT'S DUTY CYCLE = PERCENT CURRENT OUTPUT

LEGEND:

1

To get to the Home Page at any time simply press the infinity key (ˆ).

Loading...

Loading...