37

1

Instructions for the installer

Follow this procedure to adjust the other modules as well.

If the measured ow rate is too low, make sure the supply and draining

systems (the supply and draining pipes) are not obstructed.

If they are not obstructed, make sure the burner and/or exchanger

are not dirty.

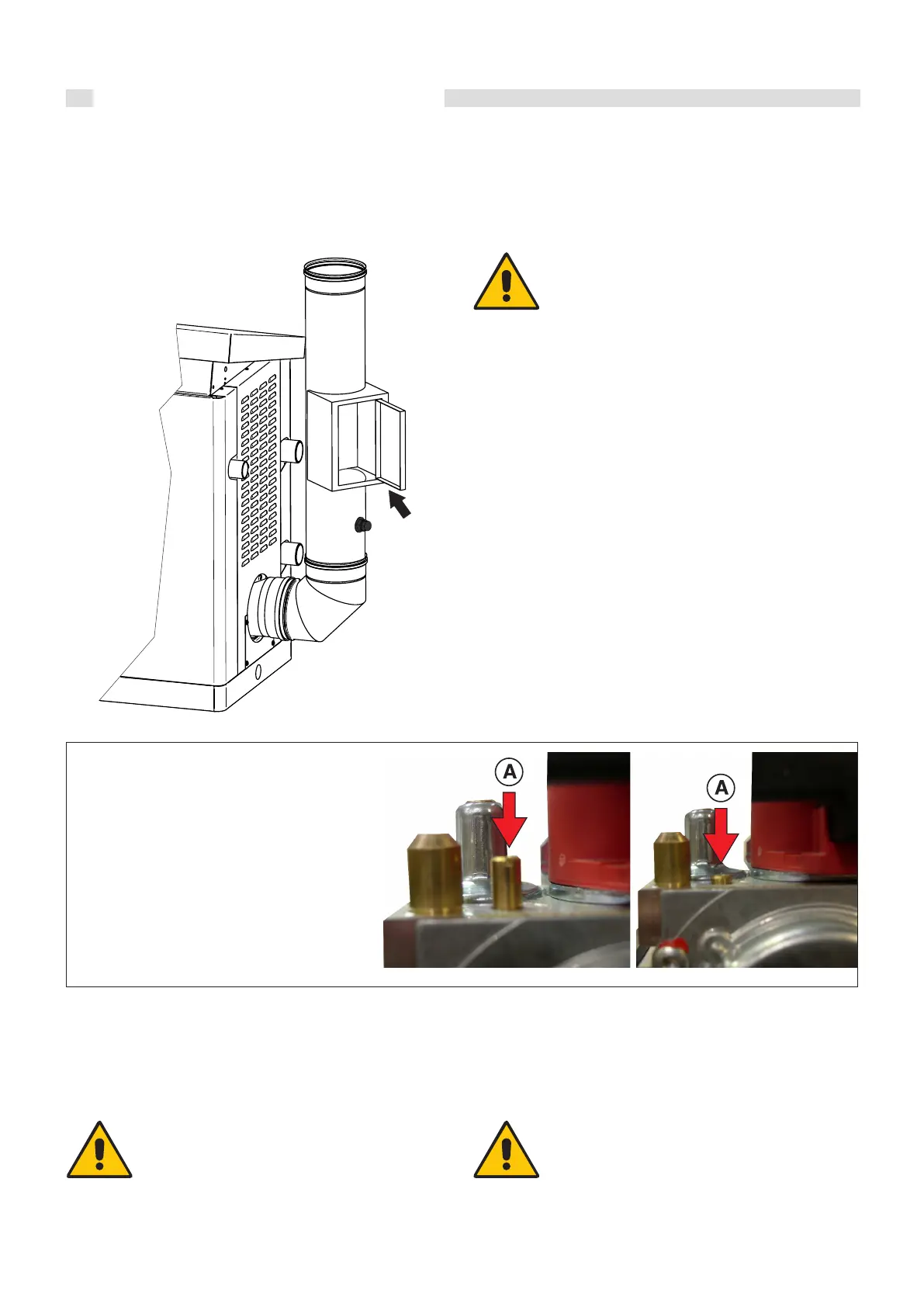

When replacing the gas valve or

having diculty with ignition:

Screw general adjusting screw "A" on clockwise until

it stops, then unscrew by 7 revolutions.

Check boiler ignition. If it does not start up unscrew

screw "A" by one more revolution, then try to start it

up again. If the boiler does not start up again, follow

the operations described above until the boiler does

start up again.

At this point adjust the burner as previously

illustrated.

ATTENTION

Calibrate the VGs (Gas Valves) in the heating control

unit referring to the procedures below.

Calibration of the VGs

must be carried out with the ue pressure = 0 Pa;

for this reason:

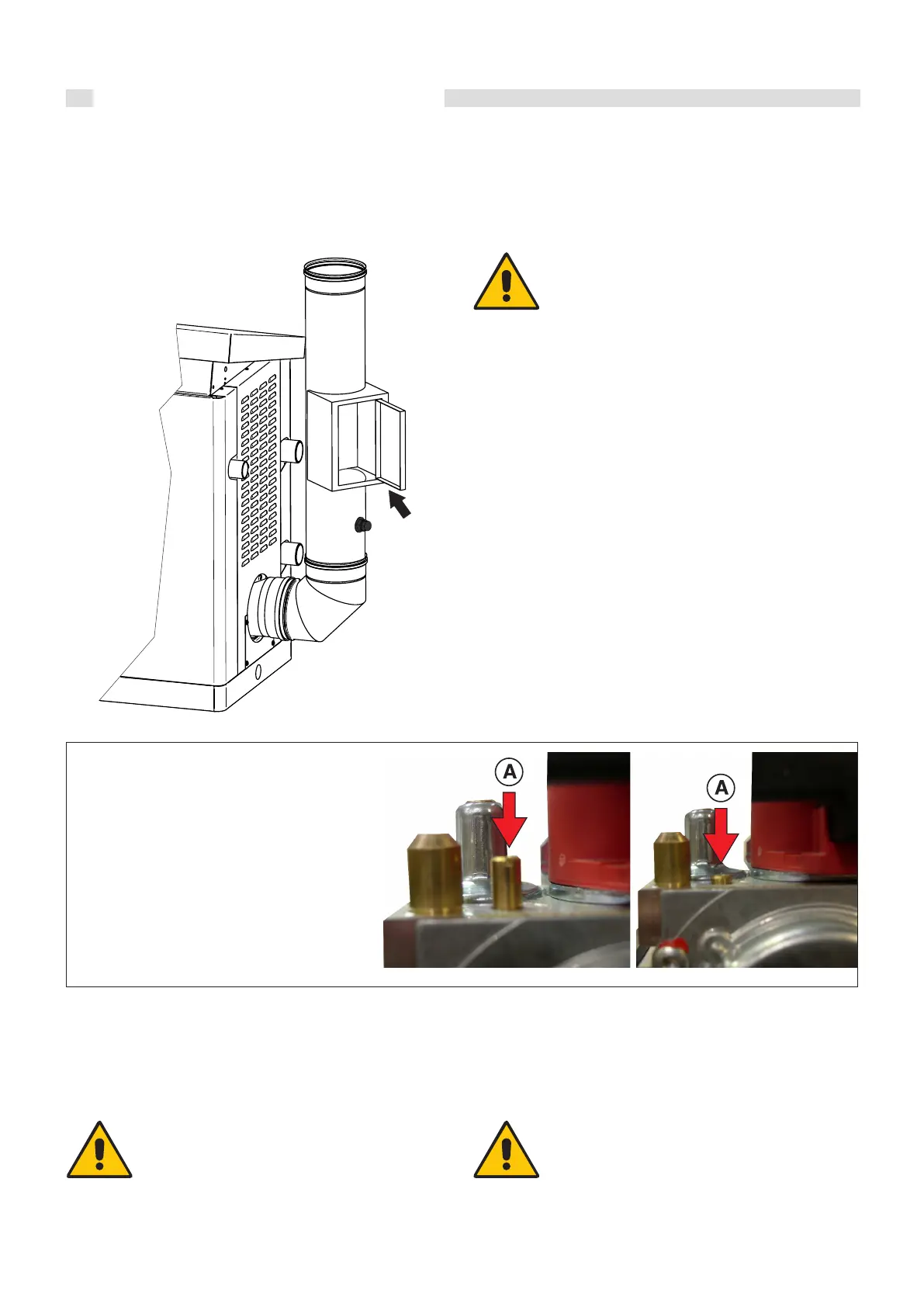

- open the inspection door of ue pipe 1;

aer calibration, close the inspection door.

3) Completing basic calibration

-

Check CO

2

values at the minimum and maximum ow rate

.

-

Touch up if necessary

.

For smooth operation, calibrate the CO

2

values taking

care to observe the values in the table.

- Close the cap (2 - 3) for the ue inspection point back up (1)

NOTE: Do not force the adjusting screw limit switch

limits.

Loading...

Loading...