103448-07 - 1/16 127

CAUTION / ATTENTION

Electrical Shock Hazard. Label all wires prior to

disconnection when servicing controls. Wiring

errors can cause improper and dangerous

operation. Verify proper operation after

servicing.

Au moment de l´entretien des commandes,

étiquetez tous les ls avant de les débrancher.

Les erreurs de câblage peuvent nuire au bon

fonctionnement et être dangereuses.

S´assurer que l´appareil fonctionne

adéquatement une fois k´entretien terminé.

acid or alkali products is prohibited. Do not use any

cleaning agents or solvents. If insulation disc has signs

of damage, it must be replaced.

8. Inspect the condensate trap to verify it is open

and free from debris. Inspect condensate line integrity

between boiler and condensate neutralizer (if used),

condensate neutralizer and the drain. Clean/repair if

needed.

If the condensate neutralizer is used, check pH before

and after the neutralizer to determine neutralizing

effectiveness. Replace limestone chips and clean out

the neutralizer if needed.

9. Inspect the ue temperature sensor cap to verify

that it is free from leakage and deterioration. Replace

if needed.

10. Inspect vent connections and vent connector to

heat exchanger seals to verify that they are free from

leakage and deterioration. Repair as needed. Follow all

instructions in Section IV “Venting” when reassembling

vent system.

11. Check for vent and air intake terminal for

obstructions and clean as necessary. Check rodent

screens in vent and air intake terminations to verify

they are clean and free of debris.

WARNING

Failure to properly secure the burner/blower/gas

valve assembly to the heat exchanger could lead

to property damage, personal injury or loss of

life.

12. Reinstall the burner/blower/gas valve assembly

and secure with M6X1 hex ange nuts. Tighten the

hex nuts in star pattern with wrench to 5Nm (44 lbf.

In) torque.

13. Reconnect any wiring which has been disconnected.

14. Verify that the system pH is between 7.5 and 9.5.

15. Inspect the heating system and correct any other

deciencies prior to restarting the boiler.

16. Follow Section IX “System Start-up” before leaving

installation.

17. Perform the combustion test outlined in Section

IX “System Start-up”.

D. Recommended Heating System Water

Treatment Products:

1. System Cleaning and Conditioning:

a. The following heating system water treatment

products are recommended for an initial existing

heating system sludge removal, initial boiler

cleaning from copper dust, ux residue and any

boiler debris and for preventive treatment as

corrosion/scale inhibitors:

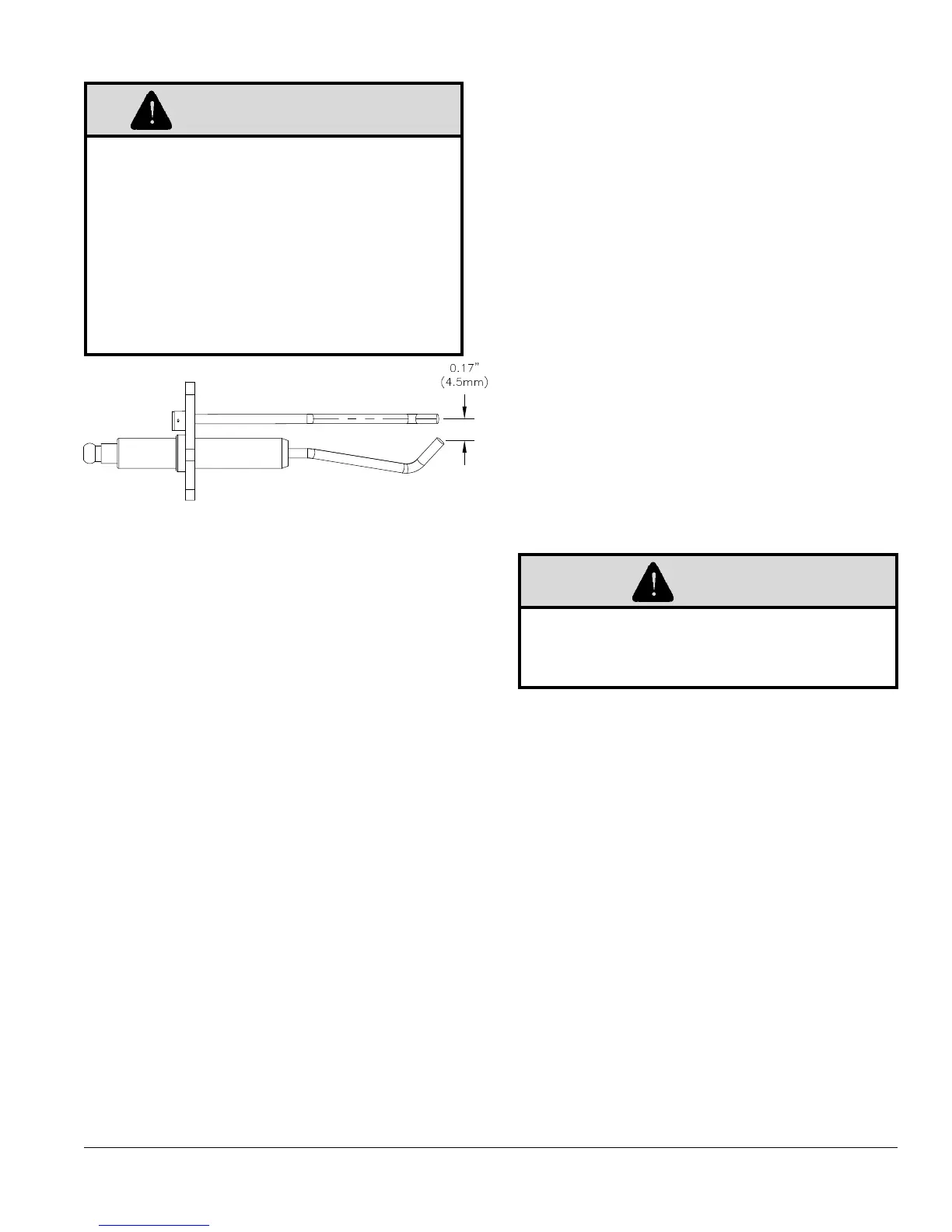

Figure 46: Igniter Electrode Gap

3. Remove the igniter assembly and ame sensor

and inspect them for oxide deposits. Clean the oxide

deposits from the igniter electrodes and ame sensor

rod with steel wool. Do not use sandpaper for the

cleaning. Inspect the ceramic insulators for cracks

and replace the igniter assembly and/or ame sensor

if necessary. Check the igniter electrode spacing gap.

Refer to Figure 46 “Igniter Electrode Gap” for details.

4. To gain access to boiler burner and combustion

chamber, rst disconnect and remove gas inlet piping

from gas valve. Then, remove six M6X1 hex ange

nuts and take out the burner/blower/gas valve assembly

from the boiler. To prevent stud breakage, apply a

generous amount of good quality penetrating oil to

nuts and let it soak in prior to attempting nut removal.

5. Inspect the assembly for lint and dust presence.

If signicant lint and dust accumulations are found,

disassemble the blower/gas valve assembly to expose

the swirl plate and blower inlet. For parts identication,

refer to Section XIII “Repair Parts”. Vacuum these

parts as required, being careful not to damage the vanes

on the swirl plate.

6. Vacuum any dust or lint from the burner if present.

If the burner shows any visual deterioration or corrosion

signs, replace it immediately. Inspect the burner gasket

and replace if necessary.

7. Inspect the heat exchanger combustion

chamber, clean and vacuum any debris found on

the surfaces. If required, brush the coils of the heat

exchanger using a non-abrasive, non-metal bristle

brush. Any cleaning of the combustion chamber with

XI. Service and Maintenance (continued)

Loading...

Loading...