103448-07 - 1/16 75

C. Refer to Figures 27 and 28 for details on the

internal boiler wiring.

Line Voltage (120 VAC) Connections - see Figure 27.

1. The line voltage connections are located in the

junction box on the left side of the vestibule. The

terminal block TB-1 in conjunction with terminal

screw identication label is attached to the junction

box combination cover/inside high voltage bracket.

2. The conductor insulation colors are:

a. Black – L1 line voltage “Hot”

b. White – L2 line voltage “Neutral” for boiler and

circulators

c. Red – Line voltage “Hot” for “Heating”

circulator, “System” circulator and “DHW”

circulator

d. Green – Ground connection

Low Voltage (24 VAC) Connections - see Figure 27.

3. The terminal block TB-2 in conjunction with

terminal screw identication label is attached to

the junction box front and located inside Sage2.2

Control compartment on the left side.

4. The connections are (listed identication

label top to bottom):

• 1 – “Heating Thermostat”

• 2 – “Heating Thermostat”

• 3 – “DHW Temperature Switch”

• 4 – “DHW Temperature Switch”

• 5 – “Outdoor Sensor”

• 6 – “Outdoor Sensor”

• 7 – “Header Sensor”

• 8 – “Header Sensor”

• 9 – “Remote Firing Rate -”

• 10 – “Remote Firing Rate +”

• 11 – “External Limit”

• 12 – “External Limit”

5. If the outdoor sensor is connected to

terminals 5 and 6 “Outdoor Sensor”, the boiler

will adjust the target space heating set point supply

water temperature downwards as the outdoor air

temperature increases. If used, this sensor should

be located on the outside of the structure in an area

where it will sense the average air temperature

around the house. Avoid placing this sensor in areas

where it may be covered with ice or snow. Locations

where the sensor will pick up direct radiation from

the sun should also be avoided. Avoid placing the

sensor near potential sources of electrical noise

such as transformers, power lines, and uorescent

lighting. Wire the sensor to the boiler using 22

gauge or larger wire. As with the sensor, the sensor

wiring should be routed away from sources of

VIII. Electrical (continued)

electrical noise. Where it is impossible to avoid such

noise sources, wire the sensor using a 2 conductor,

UL Type CM, AWM Style 2092, 300 Volt 60°C

shielded cable. Connect one end of the shielding on

this cable to ground.

NOTICE

When making low voltage connections, make

sure that no external power source is present

in the thermostat or limit circuits. If such a

power source is present, it could destroy the

boiler’s microprocessor control (Sage2.2). One

example of an external power source that could

be inadvertently connected to the low voltage

connections is a transformer in old thermostat

wiring.

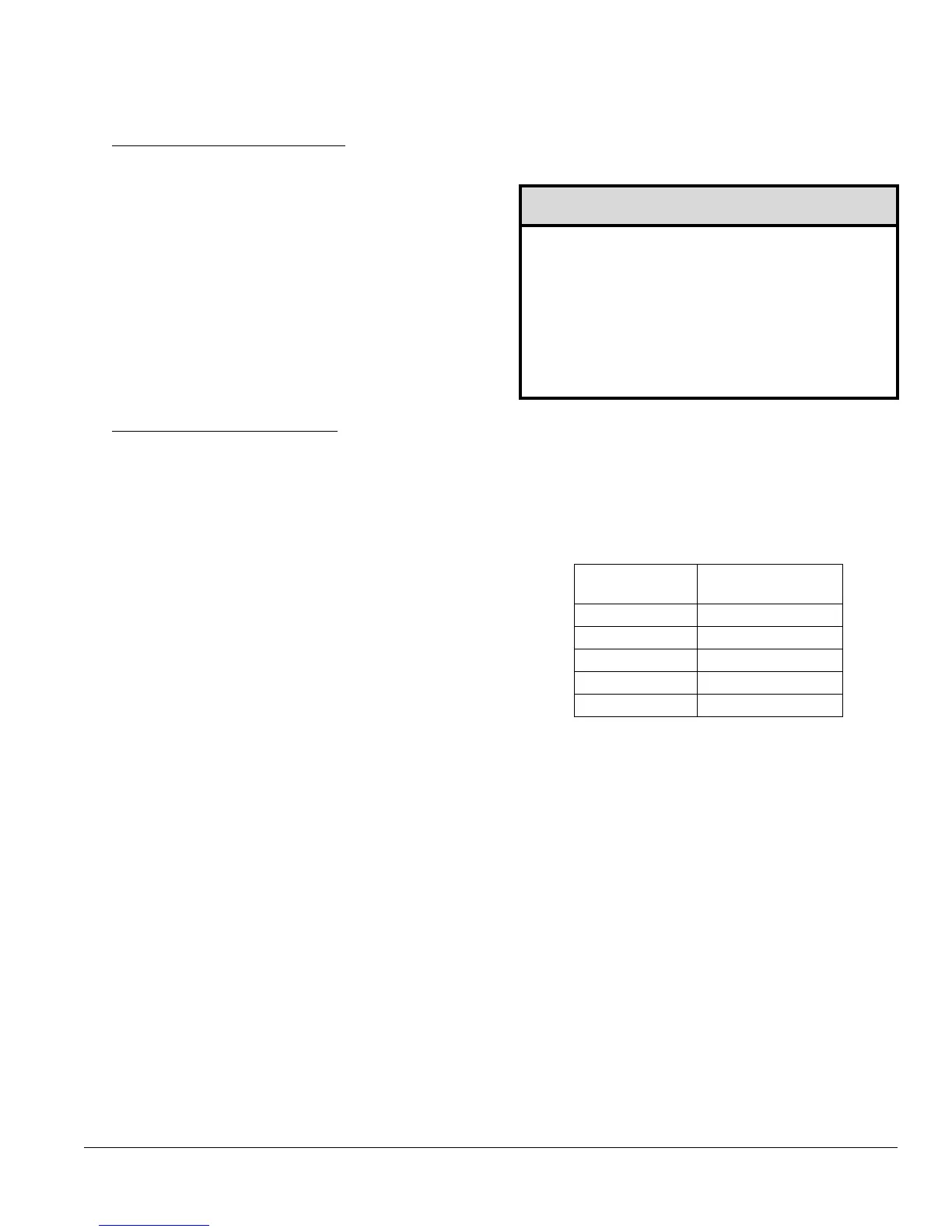

D. Power Requirements

Nominal boiler current draw is provided in Table

21. These values are for planning purposes only

and represent only the boiler’s power consumption.

To obtain total system power consumption add any

selected circulator and component current draws.

Model Number

Nominal Current

(amps)

ALP080B <2

ALP105B <2

ALP150B <2

ALP210B <3

ALP285B <5

Table 21: Boiler Current Draw

E. Multiple Boiler Wiring

Install over-current protection in accordance with

authority having jurisdiction or, in the absence of

such requirements, follow the National Electric Code,

NFPA 70, and/or Canadian Electrical Code Part 1,

CSA C22.1. Do not provide over-current protection

greater than 15 amperes. If it becomes necessary to

provide greater amperes (because of the number of

boilers provided) use separate circuits and over-current

protection for additional boilers.

F. External Multiple Boiler Control System

As an alternate to the Sage2.2 Control internal sequencer,

the Sage2.2 Control also accepts an input from an

external sequencer. Follow multiple boiler control system

manufacturer (Honeywell, Tekmar, etc.) instructions to

properly apply a multiple boiler control system. The

Tekmar Model 264 and Model 265 based control wiring

diagrams (Figures 31A and 31B) are provided as examples

of typical multiple boiler control systems.

Loading...

Loading...