62 103448-07- 1/16

VI. Water Piping and Trim D. Special Situation Installation Requirements (continued)

2. Piping with a Chiller - If the boiler is used in

conjunction with a chiller, pipe the boiler and chiller

in parallel. Use isolation valves to prevent chilled

water from entering the boiler.

3. Boiler Piping with Air Handlers - Where the

boiler is connected to air handlers through which

refrigerated air passes, use ow control valves in the

boiler piping or other automatic means to prevent

gravity circulation during the cooling cycle.

E. Multiple Boiler Installation Water Piping –

(See Table 15 and Figures 24A, 24B, 25A and 25B)

Table 15: Multiple Boiler Water Manifold Sizing

Boiler Model

Number of Boilers

2 3 4 5 6 7 8

Recommended Minimum Common Water

Manifold Size (NPT)

ALP080B 1¼” 1½” 1½” 2” 2” 2” 2½”

ALP105B 1¼” 1½” 2” 2” 2½” 2½” 2½”

ALP150B 1½” 2” 2½” 3” 3” 3” 3”

ALP210B 2” 2½” 2½” 3” 3½” 3½” 3½”

ALP285B 2” 3” 3” 3½” 4” 4” 5”

D. Special Situation Installation Requirements

Observe the following guidelines when making the

actual installation of the boiler piping for special

situations:

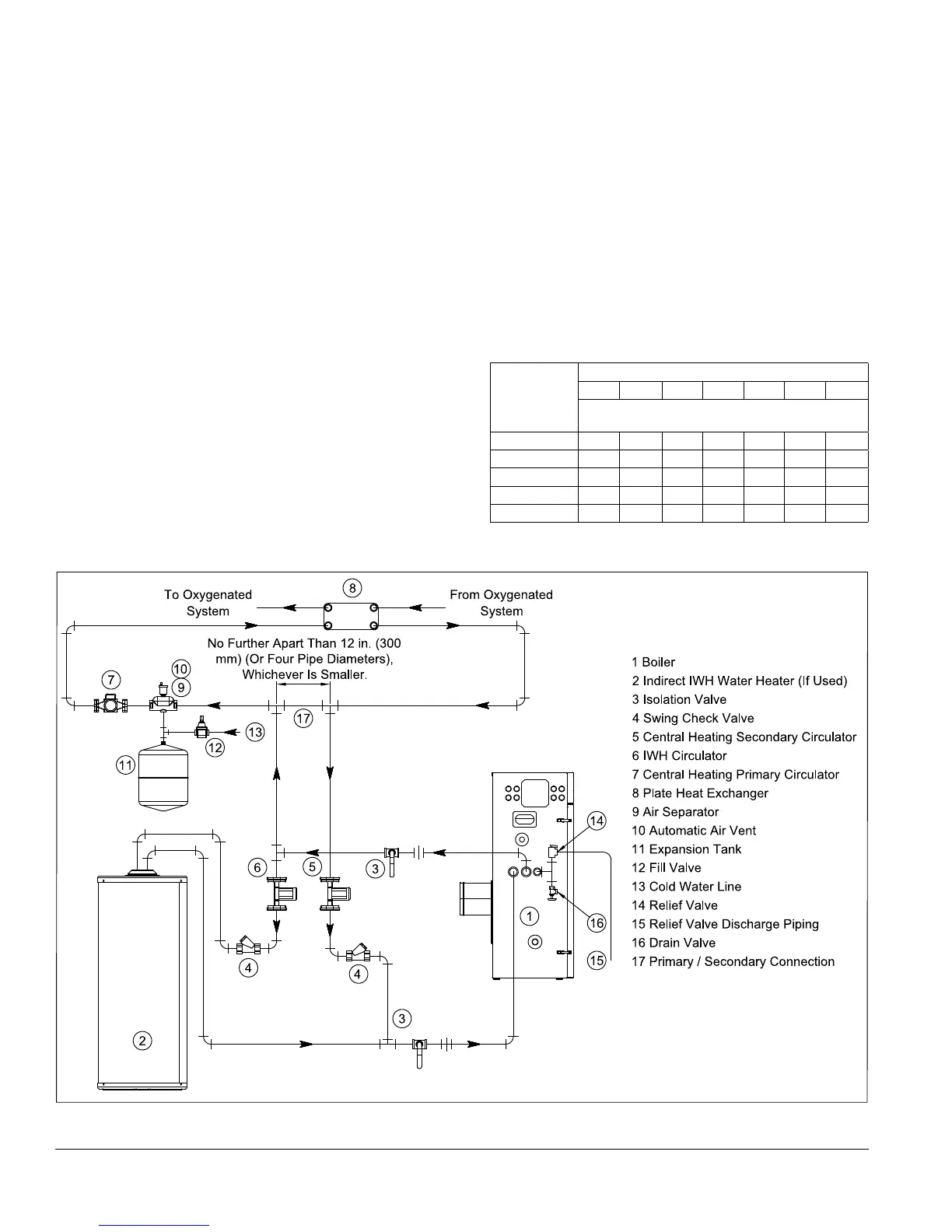

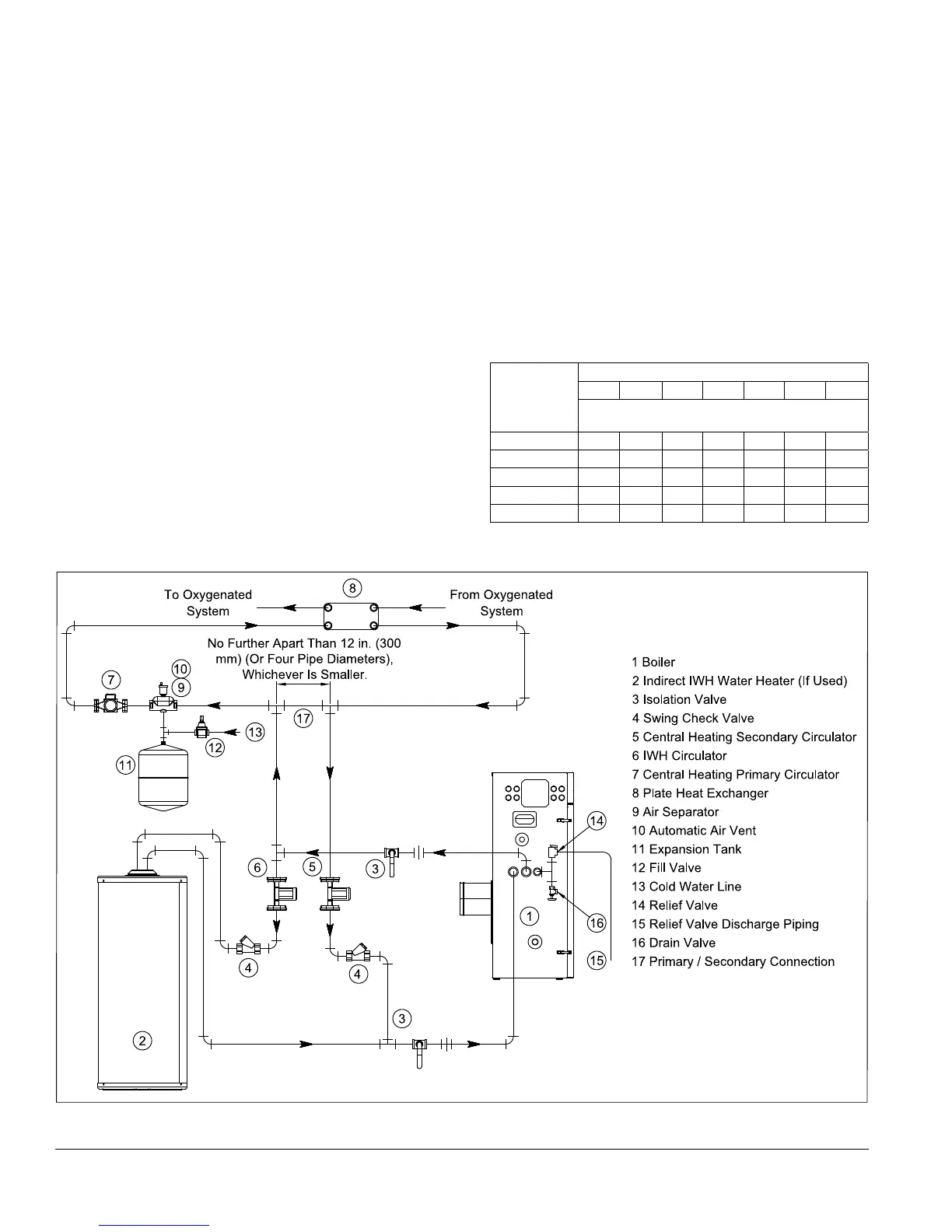

1. Systems containing high level of dissolved

oxygen – Many hydronic systems contain enough

dissolved oxygen to cause severe corrosion damage

to Alpine boiler heat exchanger. Some examples

include but not limited to:

• Radiant systems employing tubing without

oxygen barrier

• Systems with routine additions of fresh water

• Systems open to atmosphere

If the boiler is used in such a system, it must be

separated from oxygenated water being heated with

a heat exchanger as shown in Figure 23. Consult

the heat exchanger manufacturer for proper heat

exchanger sizing as well as ow and temperature

requirements. All components on the oxygenated

side of the heat exchanger, such as the pump

and expansion tank, must be designed for use in

oxygenated water.

Figure 23: Isolation of the Boiler From Oxygenated Water with A Plate Heat Exchanger

Loading...

Loading...