14

Replace adjustment cap. Wait a minimum of 10 minutes

between adjustments to allow time for the TXV and pres-

sures to stabilize.

All package units with xed orice devices are charged

using the superheat method at the compressor suction line.

To increase super heat, remove charge and to decrease

super heat, add charge. After superheat is adjusted, it is

recommended to check unit subcooling at the condenser

coil liquid line. See FIGURE 13: DESIGN SUPERHEAT

AND SUBCOOL table for targets on each model.

Single Stage Cooling Application: Refer to the Design Su-

perheat & Subcooling table

Two-Stage Cooling Application: Run unit on Low Stage

cooling and refer to Design Superheat & Subcooling table.

1. Purge gauge lines. Connect service gauge manifold

to access ttings. Run system at least 10 minutes to

allow pressure to stabilize.

2. Temporarily install thermometer on liquid (small) line

near liquid line access tting with adequate contact

and insulate for best possible reading.

3. Check subcooling and superheat. System should

have a subcooling and superheat within the range

listed on the Design Superheat and Subcooling

table.

a. If subcooling and superheat are low, adjust TXV

superheat, then check subcooling.

To adjust superheat, turn the valve stem

clockwise to increase and counterclockwise to

decrease.

b. If subcooling is low and superheat is high, add

charge to raise subcooling then check superheat.

c. If subcooling and superheat are high, adjust TXV

valve superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust

TXV valve superheat and remove charge to lower

the subcooling.

Do NOT adjust the charge based

on suction pressure unless there is a gross

undercharge.

4. Disconnect manifold set, installation is complete.

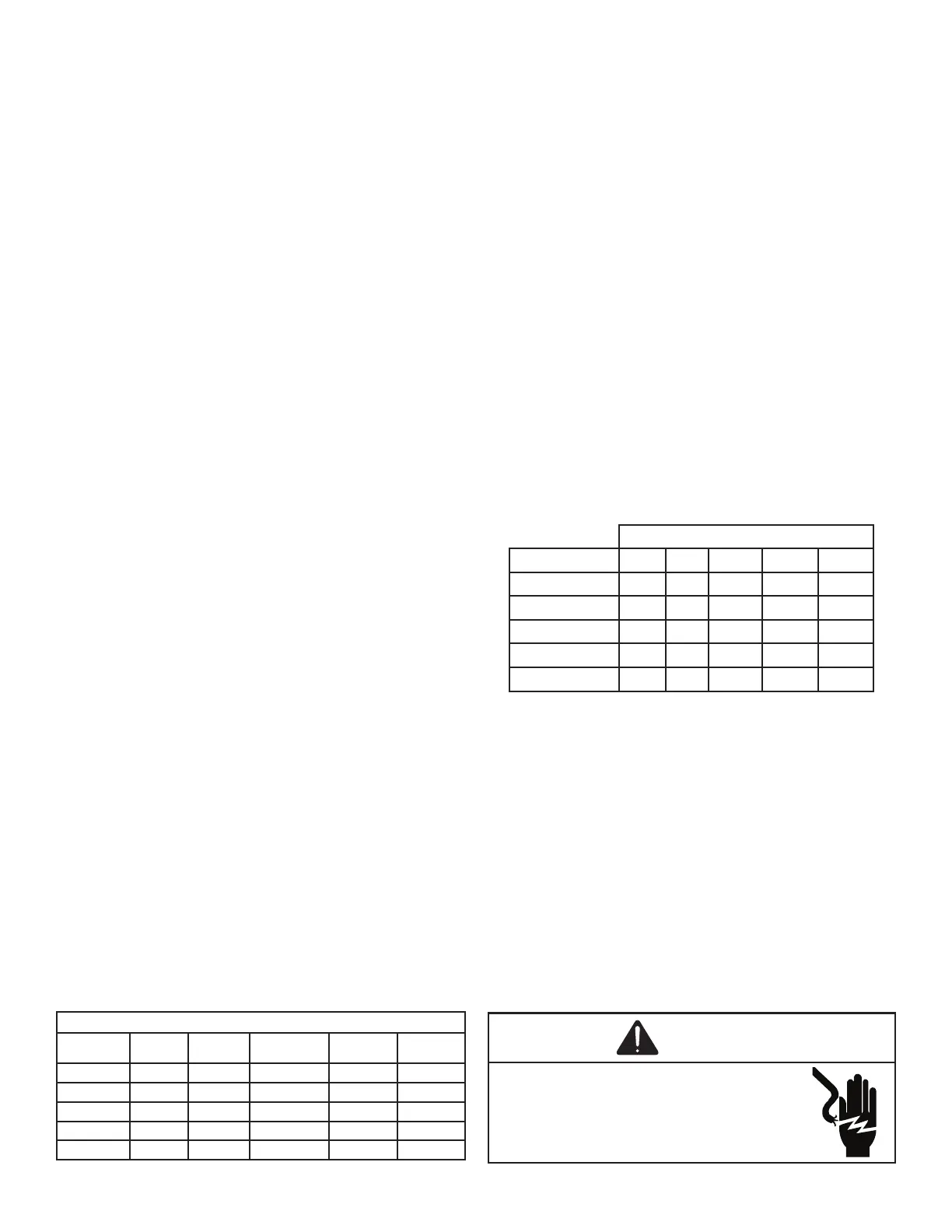

Model

Superheat

±2°F

Subcooling

±1°F

Expansion

Device

Cooling

Stage

Outdoor

ambient (°F)

APHM52441 10 6 TXV Low 82

APHM53041 5 9 TXV Low 82

APHM53641 11 7 TXV Low 82

APHM54241 8 7 TXV Low 82

APHM54841 8 9 TXV Low 82

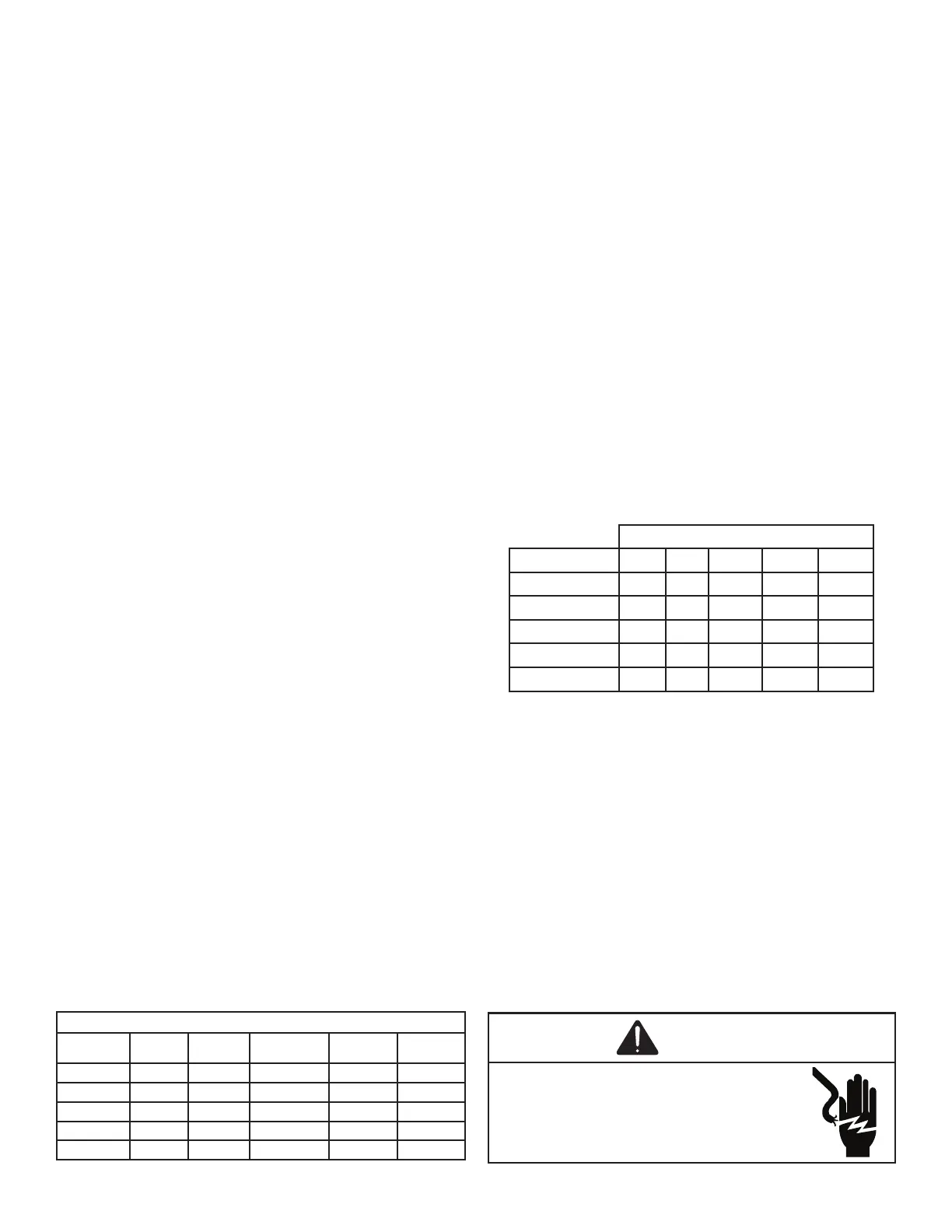

Refer to the specication manual for heater kit match up

and Heater Kit Electrical Data.

This series of electric cooling and heat pump package

equipment is designed to accept a eld installed electric

heat kit. The unit is equipped to easily install the

HKR/HKP Series Electric Heat Kit. Full Installation

Instructions are included in this kit. Please use this

document for guidance in eld equipping the package

unit with electric heat. Choose the heat kit that ts the

application for the specic installation. Permanently mark

the unit’s nameplate with the model being installed. High

and low voltage connections are detailed in the heat kit

instructions. Indoor Blower motor speed tap selection may

need to be modied to accommodate normal continuous

operation to prevent a nuisance trip. See below FIGURE

14: ELECTRIC HEAT kW.

8

APHM52441 X X X

APHM53041 X X X X

APHM53641 X X X X

APHM54241 X X X X

APHM54841 X X X X X

The Self-Contained Package Air Conditioner and Heat

Pump should operate for many years without excessive

service calls if the unit is installed properly. However,

it is recommended that the homeowner inspect the unit

before a seasonal start up. The coils should be free of

debris so adequate airow is achieved. The return and

supply registers should be free of any obstructions. The

lters should be cleaned or replaced. These few steps

will help to keep the product up time to a maximum. The

Troubleshooting Chart (see Appendix) should help in

identifying problems if the unit does not operate properly.

WARNING

Loading...

Loading...