7

Ducting work should be fabricated by the installing

contractor in accordance with local codes. Industry

manuals may be used as a guide when sizing and

designing the duct system-such as NESCA (National

Environmental Systems Contractors Association, 1501

Wilson., Arlington, Virginia 22209).

The unit should be placed as close as possible to the

space to be air-conditioned allowing clearance dimensions

as indicated. Ducts should run as directly as possible

to supply and return outlets. Use of non-ammable

weatherproof exible connectors on both supply and return

connections at the unit to reduce noise transmission is

recommended.

It is preferable to install the unit on the roof of the structure

if the registers or diusers are in the wall or ceiling. A slab

installation is recommended when the registers are low on

the wall or in the oor.

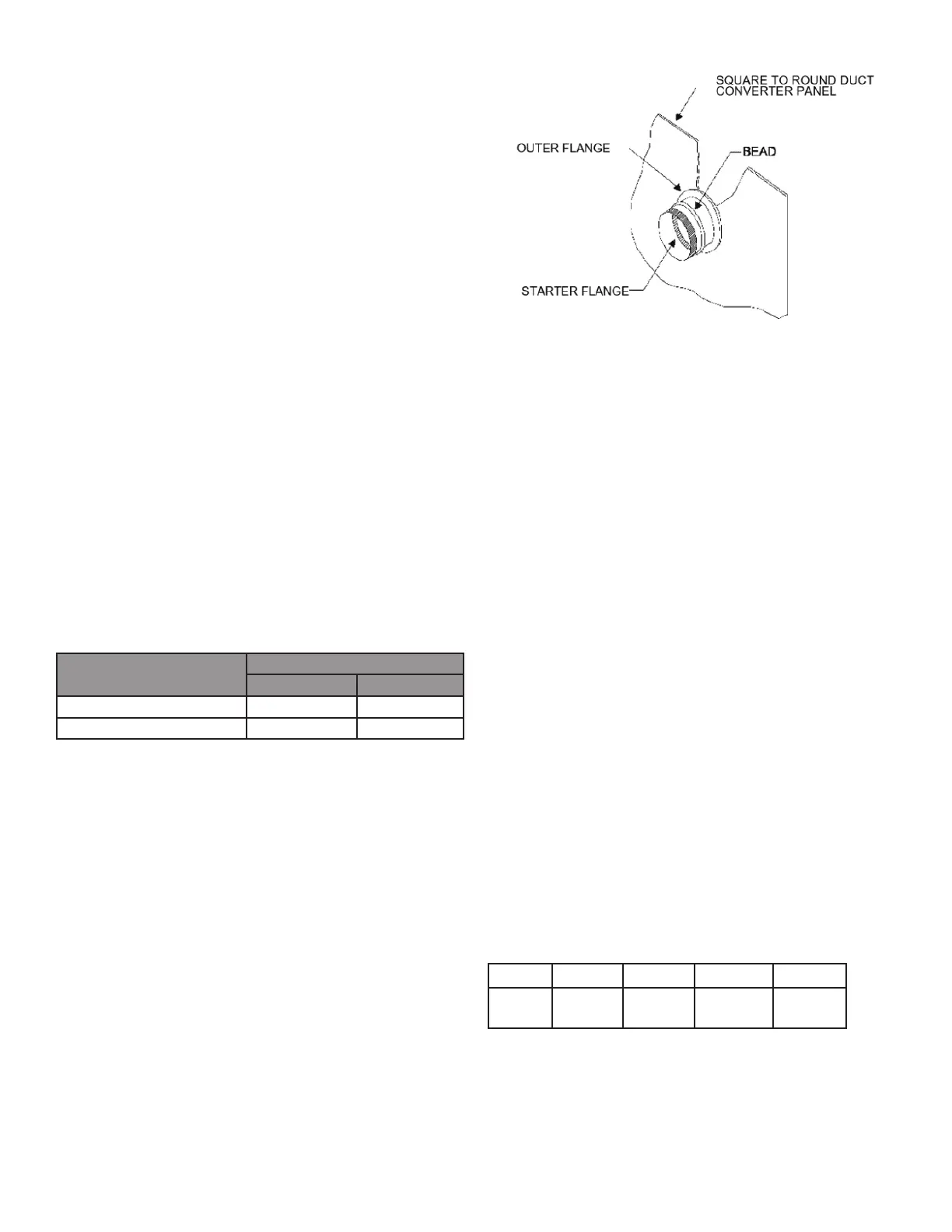

The return and supply ttings are to be attached at

the unit to a suitable square to round duct converter.

Your distributor has a factory designed square to round

converter transition. The model #’s of these kits are as

follows in the table below. (See Specication Sheets for

Dimension details).

The SQRPG101, SQRPG102, and SQRPG103 t up to

the Return and Supply Downow vents having dimensions:

Return (22 ¾” x 12 ¼”) and Supply (22 ¼” x 14 ¾”). The

SQRPGH101, SQRPGH102, and SQRPGH103 t up to

the Horizontal Return and Supply downow vents having

dimensions: Medium Chassis (16 ½” x 16 ½”) and Large

Chassis (18 ½” x 18 ½”). The Medium Chassis kits

transition to a 16” Diameter and the Large Chassis kits

transition to an 18” Diameter

(equivalent diameter, opening is oval) on the return. The

collars are to be slipped into the openings, and the anges

bent around the converter. The square to round converter

is attached to the anges of the square duct openings.

The exible duct is then clamped on to the collars. Once

the duct is axed to the unit, seal the collars and anges

with a proper waterproof sealant. SEE FIGURE 6:

MANUFACTURED HOME MODIFICATION KIT.

It is strongly encouraged to use appropriately sized ducts

based upon the CFM for your application (unit’s CFM). If

duct sizing through industry manuals or air duct calculators

requires larger ducts than converter openings, run larger

duct size up to unit converter openings and reduce with a

reducer duct tting or transition right at the unit.

A suitable plenum or square duct must be constructed. The

duct cross-sectional area should be determined by industry

duct sizing manuals or air duct calculators.

On ductwork exposed to outside air conditions of

temperature and humidity, use an insulation with a good

K factor, and a vapor barrier. Industry practices should be

followed. Balancing dampers are recommended for each

branch duct in the supply system. Ductwork should be

properly supported from the unit.

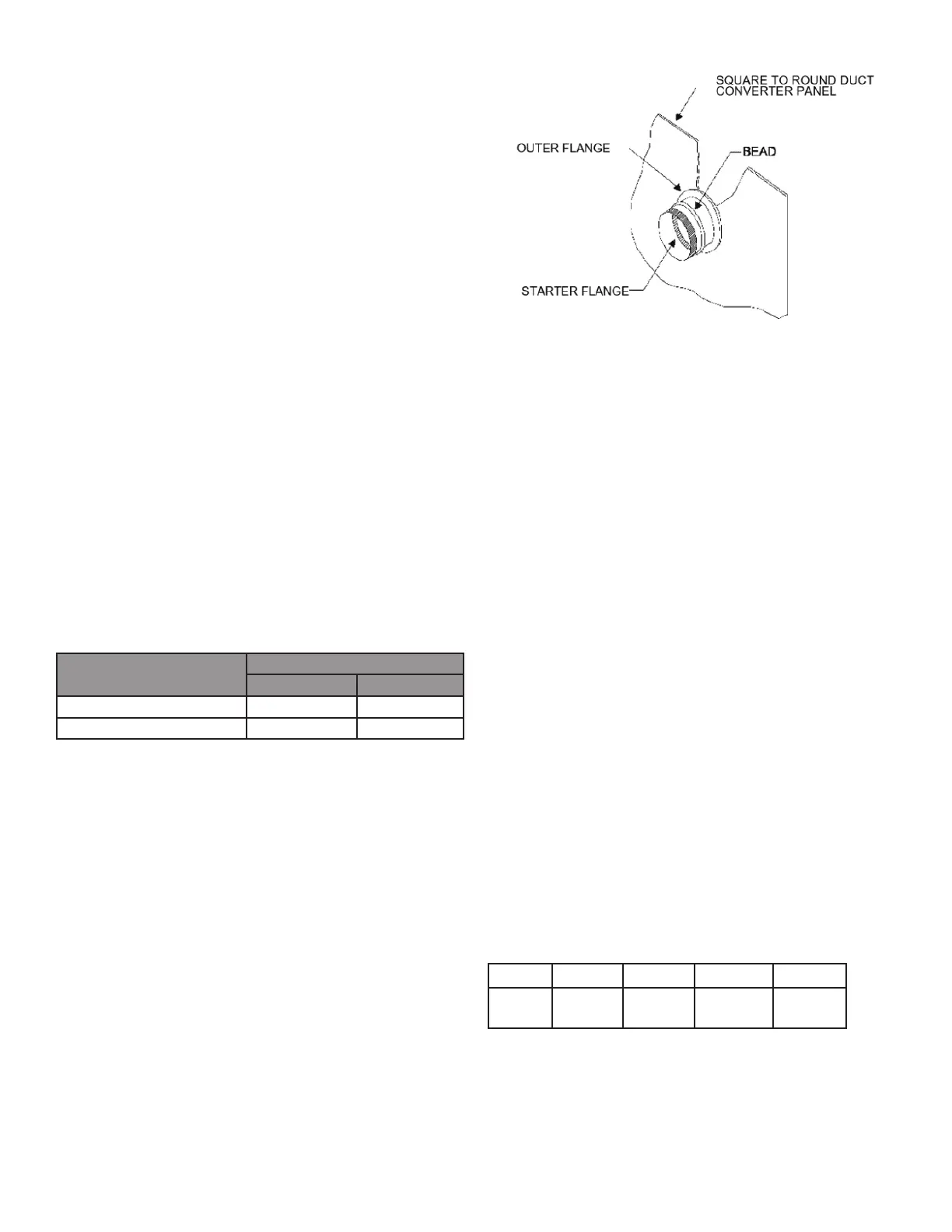

Filters are not provided with unit and must be supplied

and externally installed in the return duct system by the

installer. A eld-installed lter grille is recommended for

easy and convenient access to the lters for periodic

inspection and cleaning. When installing lters, ensure

the air ow arrows on the lter are pointing toward the

circulator blower. For unit lter size information, see table

below for recommended lter size.

UNIT

Min.

Filter

Size

(1)20X20X1

(1)20X25X1 (1)25X25X1 (2)20X20X1

Loading...

Loading...