SYSTEM OPERATION

21

determined based upon the BTU/ft

3

content of the derated

gas and the altitude. Refer to the National Fuel Gas Code,

NFPA 54/ANSI Z223.1, and information provided by the gas

supplier to determine the proper orice size.

A dierent pressure switch may be required at high altitude

regardless of the BTU/ft

3

content of the fuel used. Refer to the

product Specication Sheet or Technical Manual for a tabular

listing of appropriate altitude ranges and corresponding

manufacturer’s pressure switch kits.

WARNING

P

SSILE PRPER DAMAGE PERSNAL INJR R DEA MA CCR I

E CRREC CNVERSIN KIS ARE N INSALLED

E APPRPRIAE KIS

MS E APPLIED INSRE SAE AND PRPER RNACE PERAIN

A

LL

CNVERSINS MS E PERRMED A QALIIED INSALLER R SERVICE

AGENC

This unit is configured for natural gas. The appropriate

manufacturer’s propane gas conversion kit, must be applied

for propane gas installations.

**ES9* models using a White-Rodgers 36J22 single stage

valve use LPM-07 LP Conversion Kit.

GAS VALVE

This unit is equipped with a 24 volt gas valve controlled

during furnace operation by the integrated control module.

As shipped, the valve is congured for natural gas. The valve

is eld convertible for use with propane gas by using the

appropriate propane gas conversion kit. Taps for measuring

the gas supply pressure and manifold pressure are provided

on the valve.

The gas valve has a manual ON/OFF control located on

the valve itself. This control may be set only to the “ON” or

“OFF” position. Refer to the Lighting Instructions Label or the

“Putting the Furnace Into Operation” section of this manual or

the installation instructions for use of this control during start

up and shut down periods.

AVID PSSILE NSAISACR PERAIN R EQIPMEN DAMAGE

DE NDERIRING EQIPMEN SE E PRPER SIE

NARAL/PRPANE GAS PIPING NEEDED WEN RNNING PIPE RM E

MEER/ANK E RNACE

The gas piping supplying the furnace must be properly sized

based on the gas ow required, specic gravity of the gas,

and length of the run. The gas line installation must comply

with local codes, or in their absence, with the latest edition of

the National Fuel Gas Code, NFPA 54/ANSI Z223.1.

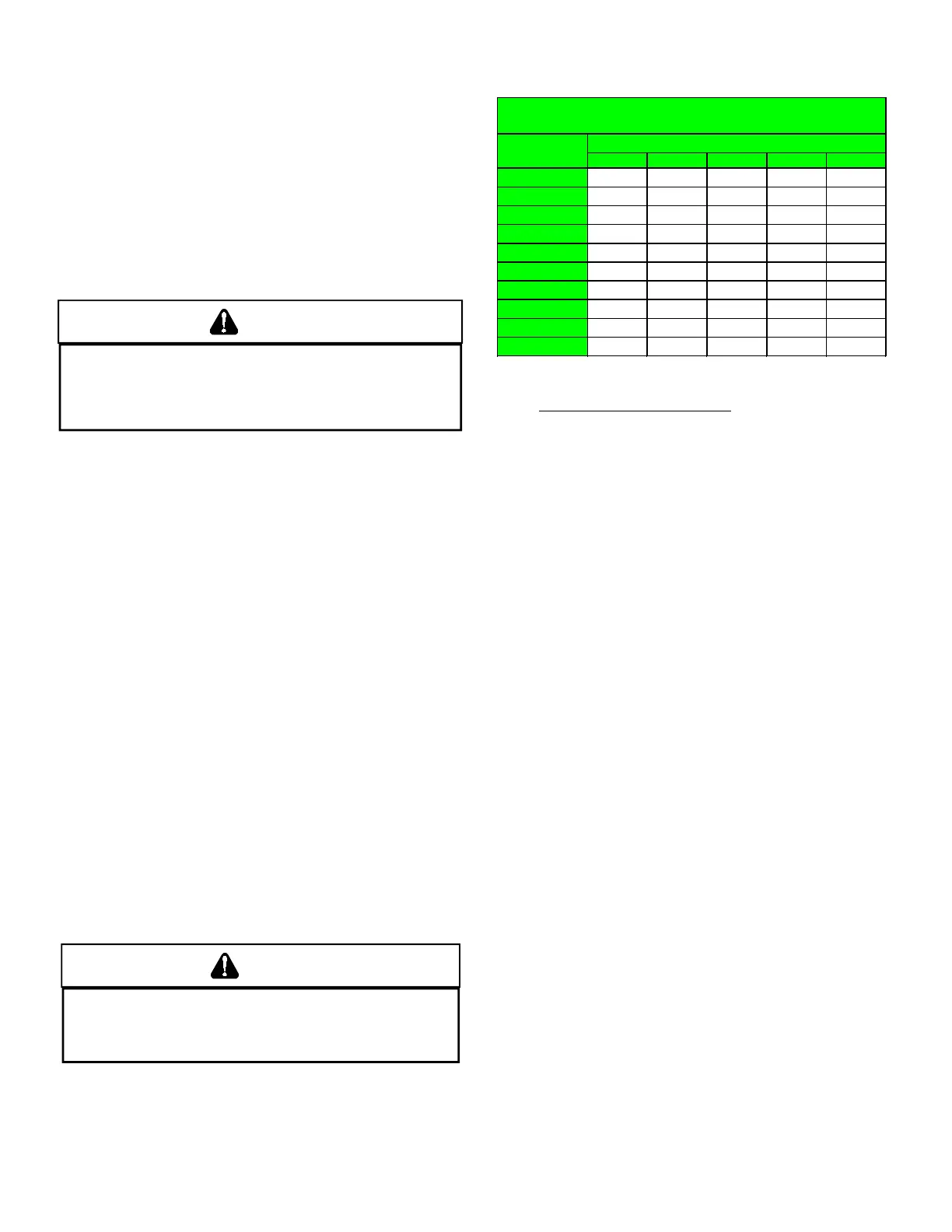

Length of

Nominal Black Pipe Size

Pipe in Feet 1/2" 3/4" 1" 1 1/4" 1 1/2"

132 278 520 1050 1600

92 190 350 730 1100

73 152 285 590 980

63 130 245 500 760

56 115 215 440 670

50 105 195 400 610

46 96 180 370 560

43 90 170 350 530

40 84 160 320 490

38 79 150 305 460

CFH =

(Pressure 0.5 psig or less and pressure drop of 0.3" W.C.; Based on 0.60

Specific Gravity Gas)

BTUH Furnace Input

Heating Value of Gas (BTU/Cubic Foot)

To connect the furnace to the building’s gas piping, the installer

must supply a ground joint union, drip leg, manual shuto

valve, and line and ttings to connect to gas valve. In some

cases, the installer may also need to supply a transition piece

from 1/2” pipe to a larger pipe size.

The following stipulations apply when connecting gas piping.

Refer to the following gures for typical gas line connections

to the furnace.

1. Use black iron or steel pipe and ttings for the building

piping.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of the

fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum of

three inches long.

5. Install a 1/8” NPT pipe plug tting, accessible for test

gage connection, immediately upstream of the gas

supply connection to the furnace.

6. Use two pipe wrenches when making connection to

the gas valve to keep it from turning. The orientation of

the gas valve on the manifold must be maintained as

shipped from the factory.

7. Install a manual shuto valve between the gas meter

and unit within six feet of the unit. If a union is installed,

the union must be downstream of the manual shuto

valve, between the shuto valve and the furnace.

8. Tighten all joints securely.

Loading...

Loading...