SYSTEM OPERATION

22

Before placing unit in operation, leak test the unit and gas

connections.

WARNING

AVID E PSSILI EXPLSIN R IRE NEVER SE A MAC

R PEN LAME ES R LEAKS

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or

other approved testing methods.

Never exceed specied pressures for testing. Higher

pressure may damage the gas valve and cause subsequent

overring, resulting in heat exchanger failure. Disconnect

this unit and shuto valve from the gas supply piping system

before pressure testing the supply piping system with

pressures in excess of 1/2 psig (3.48 kPa). Isolate this unit

from the gas supply piping system by closing its external

manual gas shuto valve before pressure testing supply

piping system with test pressures equal to or less than 1/2

psig (3.48 kPa).

WARNING

P

RPANE GAS IS EAVIER AN AIR AND AN LEAKING GAS CAN SELE IN

AN LW AREAS R CNINED SPACES

PREVEN PRPER DAMAGE

PERSNAL INJR R DEA DE IRE R EXPLSIN CASED A

PRPANE GAS LEAK INSALL A GAS DEECIN WARNING DEVICE

A gas detecting warning system is the only reliable way to

detect a propane gas leak. Iron oxide (rust) can reduce the

level of odorant in propane gas. Do not rely on your sense of

smell. Contact a local propane gas supplier about installing

a gas detecting warning system. If the presence of gas is

suspected, follow the instructions on this page.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters, NBFU

Manual 58.

For satisfactory operation, propane gas pressure must be

10 inch WC at the furnace manifold with all gas appli ances

in operation. Maintaining proper gas pressure depends on

three main factors:

1. Vaporization rate, depending on temperature of the liquid,

and “wetted surface” area of the con tainer or containers.

2. Proper pressure regulation. (Two-stage regulation is

recommended for both cost and eciency).

3. Pressure drop in lines between regulators, and between

second stage regulator and the appliance. Pipe size

will depend on length of pipe run and total load of all

appliances.

Complete information regarding tank sizing for vaporiza-

tion, recommended regulator settings, and pipe sizing is

available from most regulator manufacturers and propane

gas suppliers.

Use pipe dope approved for use with L.P. gas.

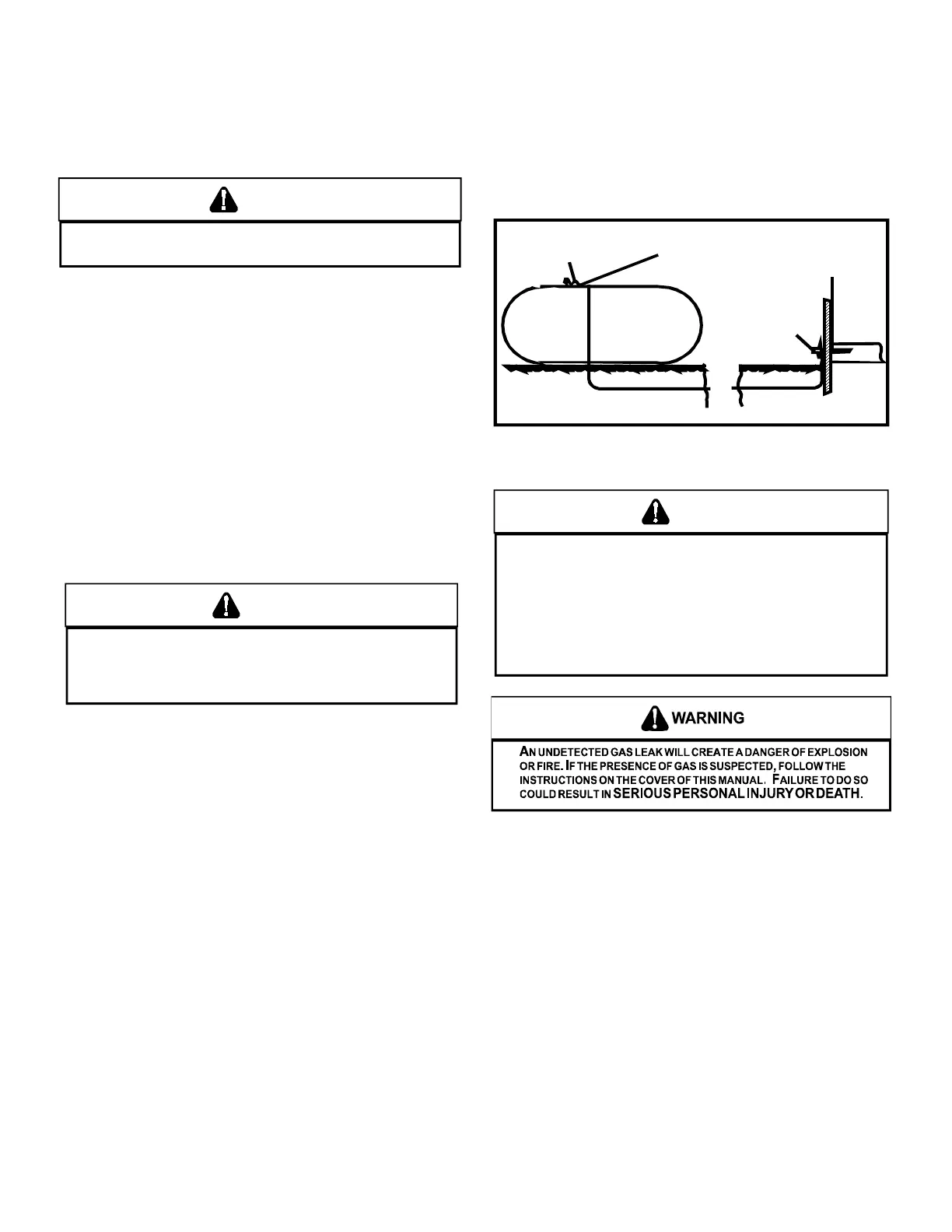

Refer to the following illustration for typical propane gas

installations and piping.

WARNING

I

E GAS RNACE IS INSALLED IN A ASEMEN AN EXCAVAED

ARE

A

R A CN

INED

SPACE

I

IS SRNGL

RECMMEN

DED

CNAC A PRPANE SPPLIER INSALL A GAS DEECING

WARNING DEVICE IN CASE

A GAS LEAK

•

S

IN

CE PRPANE GAS IS EA

VIER AN AIR AN LEAK

ING GAS CAN

SELE IN AN LW AREAS R CNINED SPACES

•

P

RPANE GAS DRAN MA ADE MAKING E GAS NDEECALE

EXCEP WI A WARNING DEVICE

Loading...

Loading...