6.1 General notes

Careful maintenance:

ð increased service life

ð increased function security

ð reduced downtimes

ð increased reliability

ð reduced repair costs

•

Observe the safety regulations!

•

Maintenance works should only be carried out when the

engine is shut off.

•

The engine and machine should be cleaned thorougly be

-

fore carrying out maintenance work.

•

Park the machine on a flat surface and secure it against

rolling away and slipping.

•

Ensure that operating materials and replaced parts are

disposed of safely and in an environmentally - friendly

way.

•

Before commencing work on any electrical equipment,

disconnect the battery and cover it with insulating mate

-

rials.

•

Do not exchange «PLUS» and «MINUS» poles on the bat

-

tery.

•

It is essential that short-circuits be prevented in cables

carrying current.

•

Before welding works on the machine put-off all connec

-

tions and battery cables.

•

Burn-out lightbulbs in indicator lamps should be re

-

placed immediately.

•

When cleaning the machine with a high-pressure water

jet, do not spray the electrical components directly.

•

After washing the components, blow-dry them with com

-

pressed air in order to prevent surface leakage current

and corrosion.

6. Maintenance

43

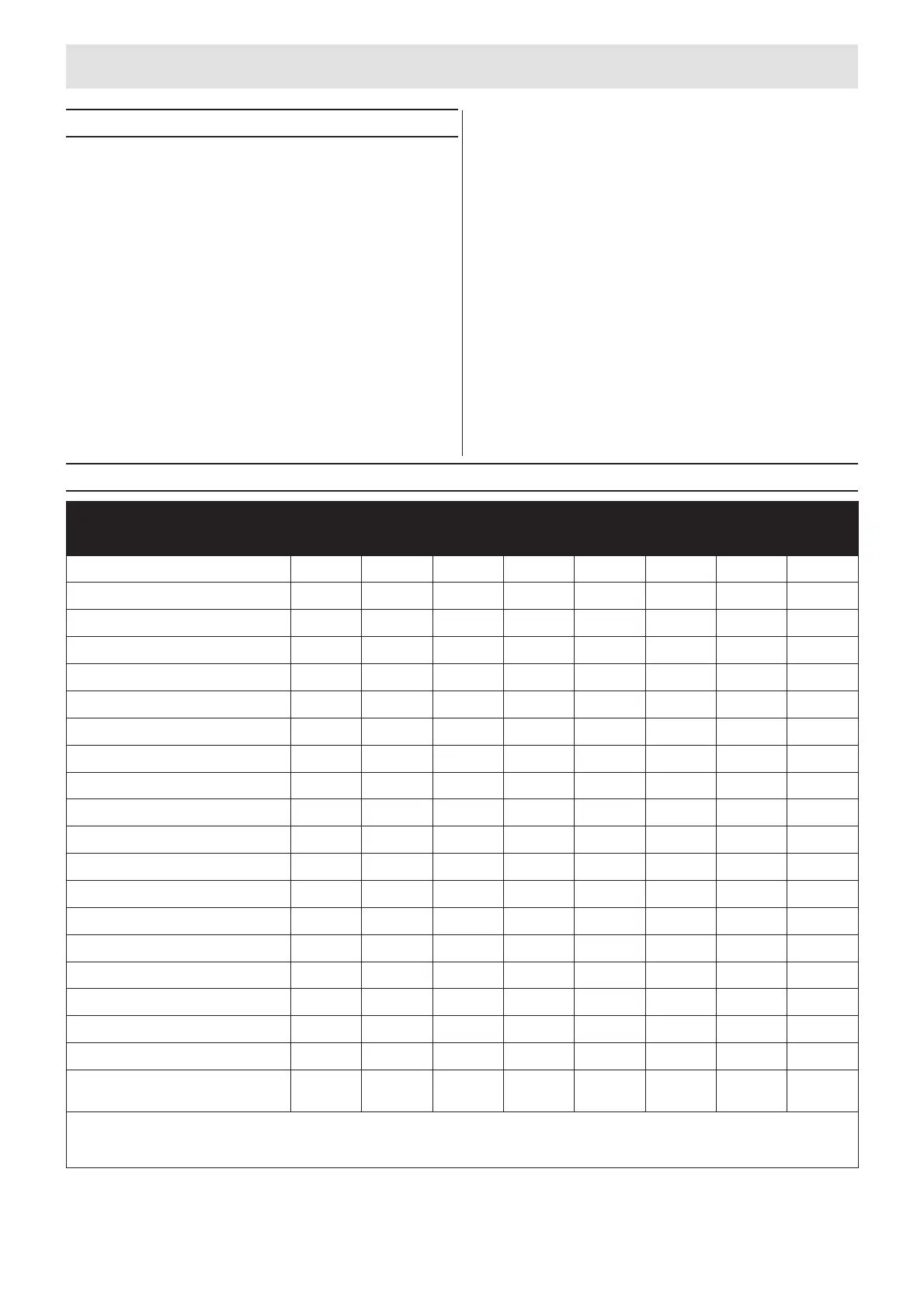

6.2 Maintenance schedule

Intervals

daily 20 h 50 h 100 h 250 h 500 h 1000 h

if neces

-

sary

Works

Clean machine

l

Check engine oil level

1)

l

Change engine oil

1)

l

3)

l

Change engine oil filter

1)

l

3)

l

Check air filter

1)

l

Change air filter element

1)

ll

Check suction air intake

1)

l

Drain water (Fuel tank)

1)

l

Change fuel filter

1)

l

Check valve clearance

1)

l

3)

l

Exciter: Check oil level

l

Exciter: Change oil

2)

l

3)

l

Check hydraulic oil level

l

Change hydraulic oil

2)

l

3)

l

Change return filter element

2)

l

3)

l

Change ventilation filter

2)

l

3)

l

Clean suction filter

2)

l

3)

l

Check hydraulic hose lines

l

Check rubber buffers

l

Check screwed connections for tight

-

ness

l

3)

l

1)

See engine operating manual

2)

minimum once a year

3)

for the first time

Loading...

Loading...