Ampcontrol Pty Ltd – ABN 28 000 915 542

OCS USER MANUAL

MAG-182 Version 5 – FEB/2020

Uncontrolled Copy - Refer to Ampcontrol Website for Latest Version

APPROVED FOR EXTERNAL DISTRIBUTION

– PROPERTY OF AMPCONTROL PTY LTD

– NOT TO BE REPRODUCED IN PART

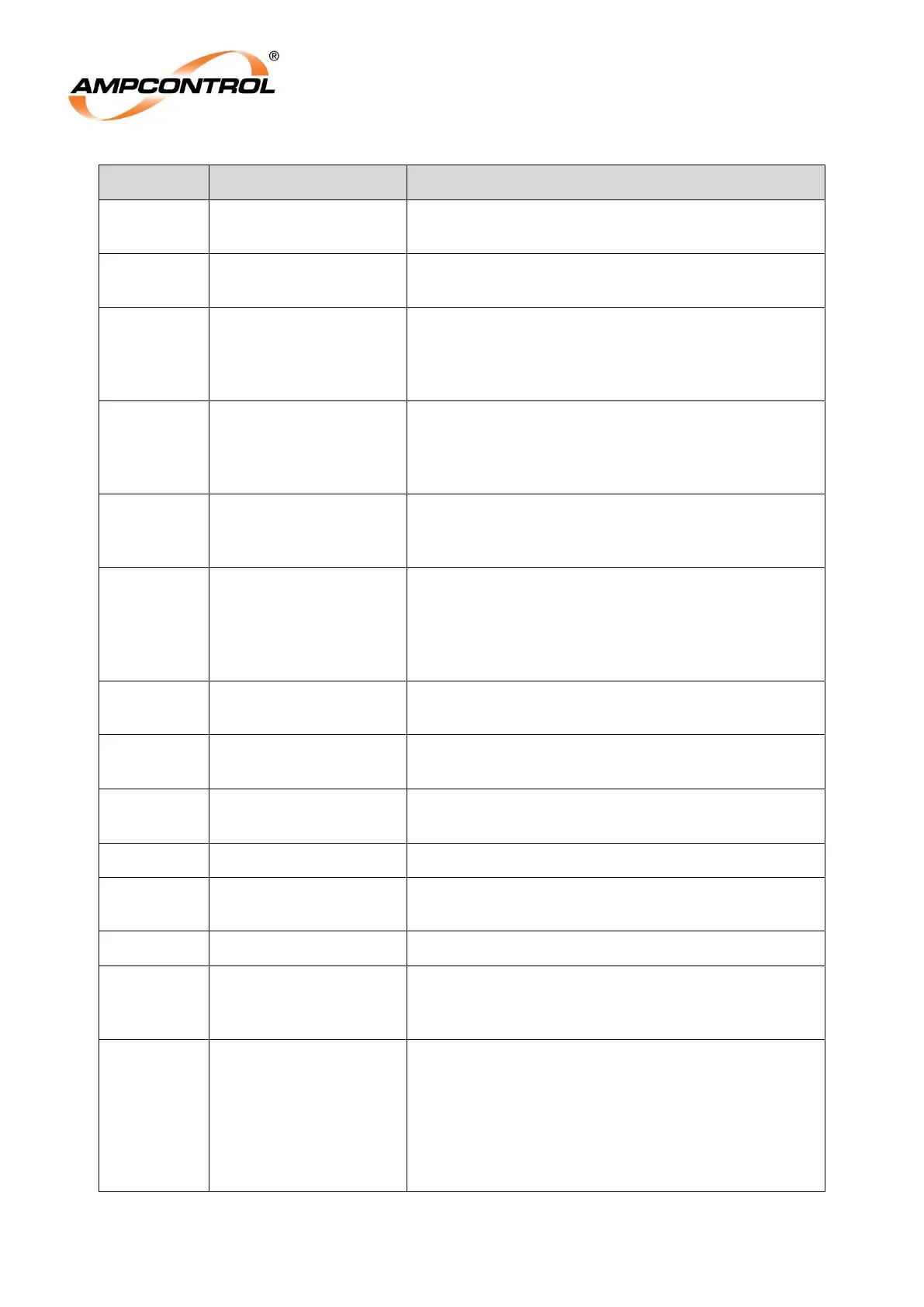

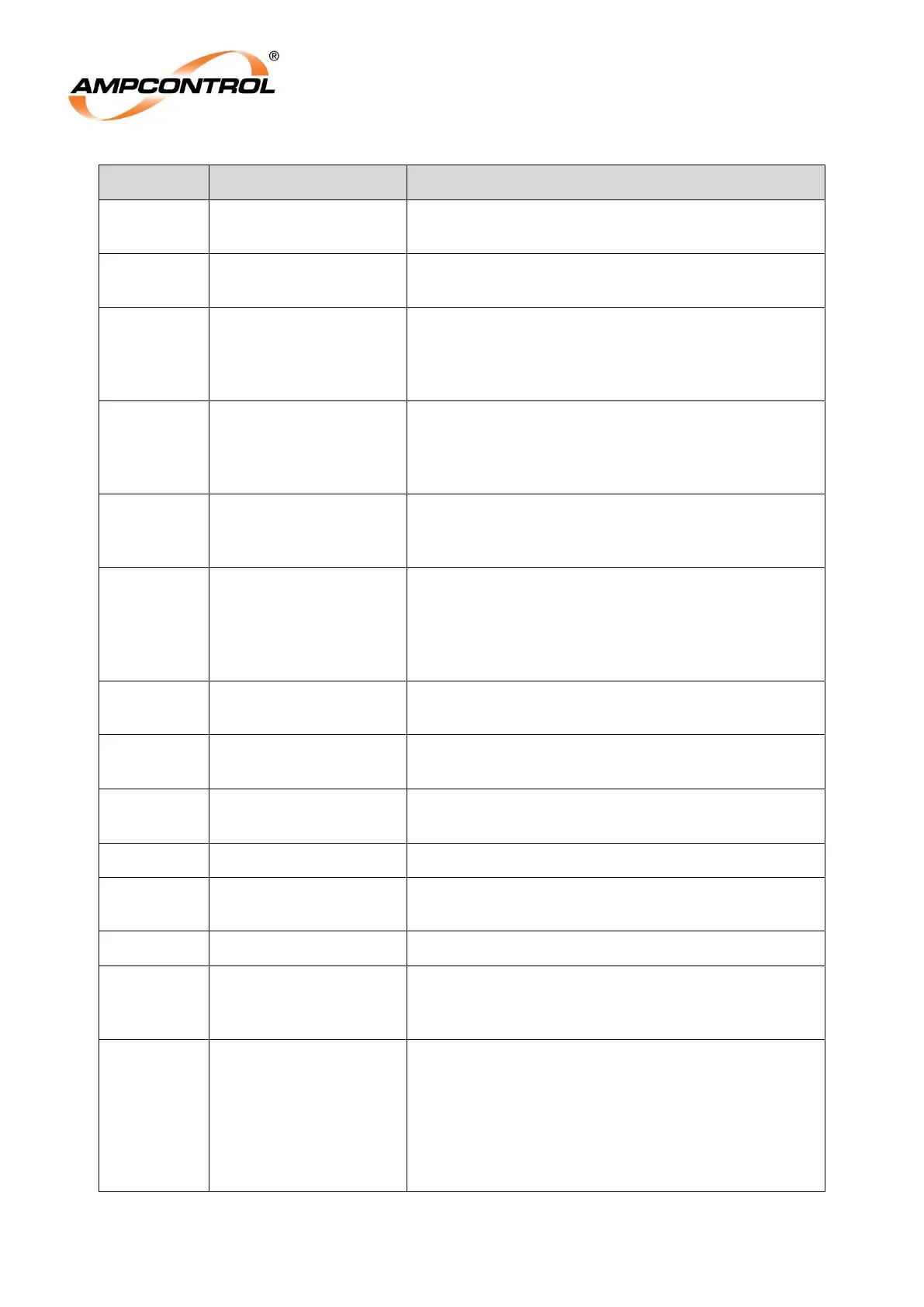

An earth leakage trip was reset.

The clock time was not able to be read from the Real

Time Chip.

MCF Battery Under

Voltage

The Battery which stores the Main Contactor Failure

state and powers the Battery Backed Ram is under

Voltage (e.g. the battery has reached the end of its

life)

Notes that the value of the control mask has been

changed (e.g. a Test Relay has been closed). Data1

stores the old mask value; Data2 stores the new

mask value.

Logs the fact an invalid CCM was attached to the

Protection Element. This is the logged version of a

‘CCM ID’ trip.

An Error has occurred in the operation of the code

within the Protection Element. The log is used to

denote that the stack has grown too big or that the

system has run out of RAM. In normal operation

neither of these things should occur.

The outlet was stopped due to the RTX’s PTC input

exceeding its trip resistance level.

The outlet was stopped due to one of the RTD inputs

within group 1 going above the set trip level.

The outlet was stopped due to one of the RTD inputs

within group 2 going above the set trip level.

Short Circuit ‘Long Time’ tripped.

Residual voltage was measured above the selected

trip level.

A residual voltage trip was reset.

The Fast element of the earth continuity detected

resistance in excess of 100 Ohms for the selected

trip time.

To work out which parameter was modified, minus

128 from the Event ID (eg 130 means parameter 2

was modified) Outlet parameters are numbered 0-

29, Dongle Load parameters are numbered 30-59

and RTX Load parameters are numbered 60-89. The

value which was changed from is stored in Data1

and the new value is in Data2.

Loading...

Loading...