58

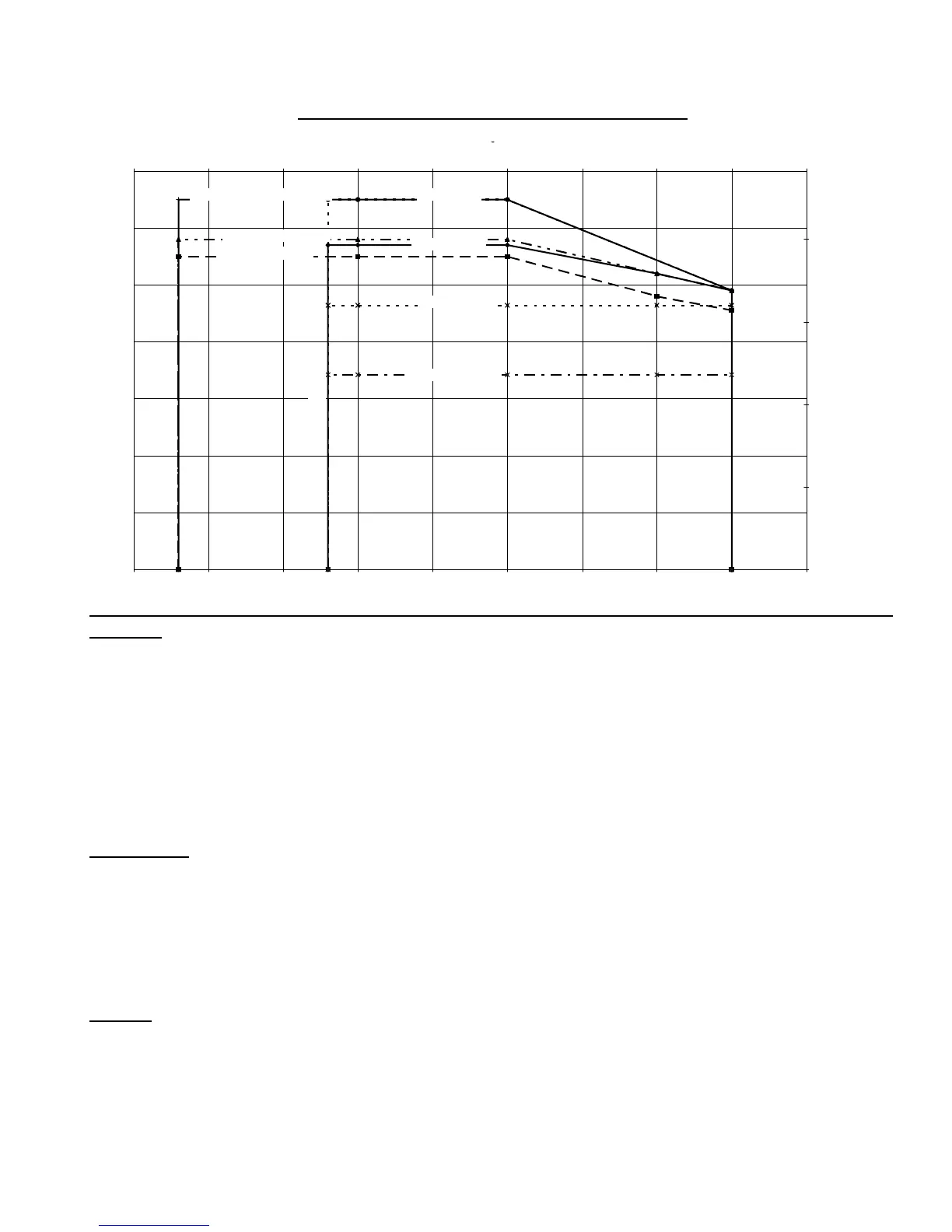

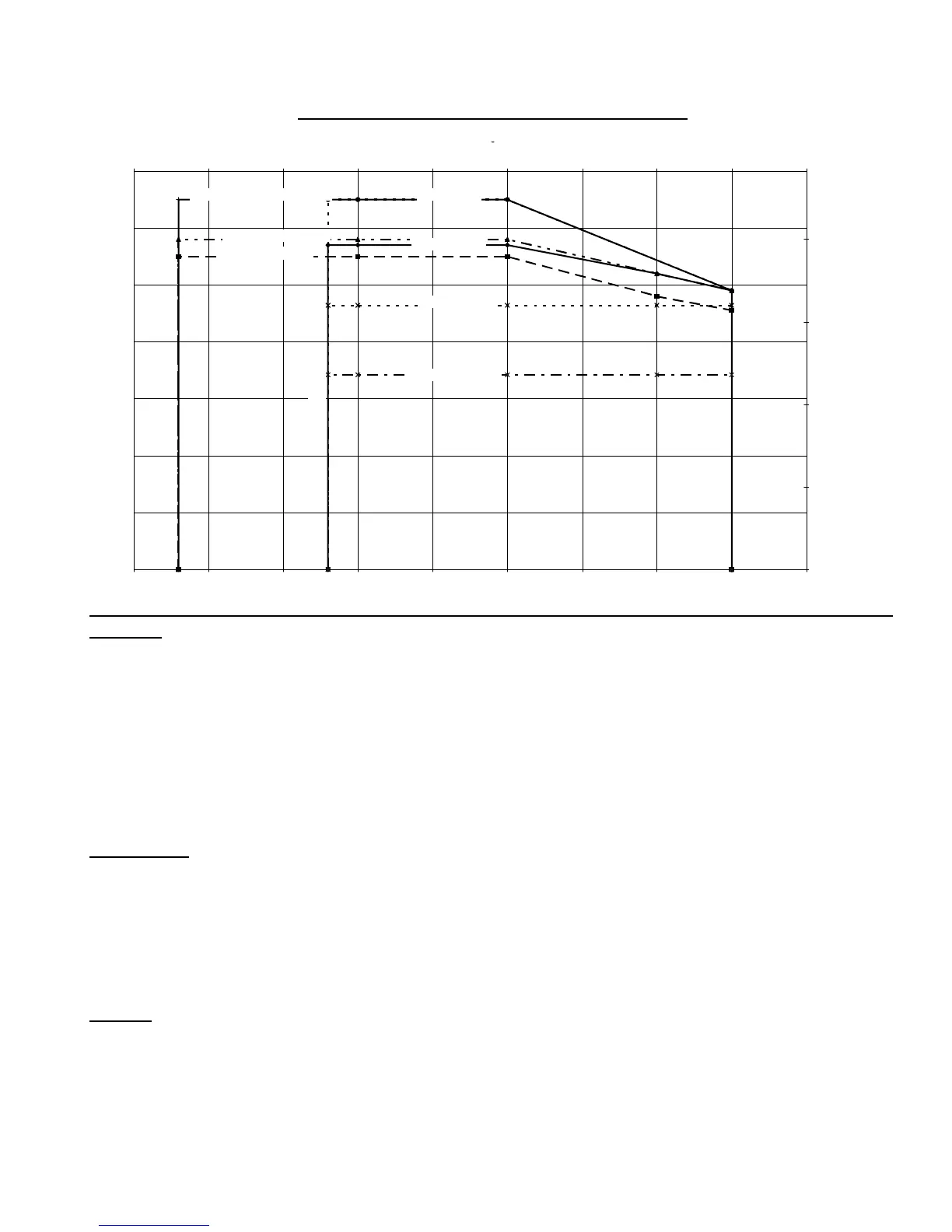

PRESSURE & TEMPERATURE CAPABILITY

-20

0

50

100

150

200

250

300

350

-150 -100 -50 0 50 100 150 200 250 300

Tem

erature

F

Pressure

si

0

5

10

15

20

-100 -75 -45 10 40 65 95 120 150

em

era

ure

NSI 150

DI

6&8"

ANSI 150

HAST B&C

6&8"

COLD LIMIT FOR ALL DI

NSI 300

DI

8"

ISO PN16

DI

6&8"

ANSI 150

316SS

6&8"

ANSI 300

316SS & HAST B&C

6&8"

JIS 10k

/cm2

DI

6&8"

CASING

• Meets ANSI B73.3 or ISO 2858 or JIS B8313 foot and flange position and size standard

• Self-venting and top centerline discharge.

• Material: One piece solid ductile iron casing, lined with rotomolded ETFE fluoropolymer 1/8 in. (3 mm) min.

Optional (ANSI models, only): Alloy casing in 316 SS, Hastelloy® B or Hastelloy® C (no lining).

• Foot supported for maximum resistance to distortion from pipe loads.

• Pure sintered silicon carbide thrust ring integral with front shaft support.

• Flanges: ANSI/ASME B16.5 Class 150 or ISO 2084 Class NP 16 flanges standard.

Optional: ANSI/ASME B16.5 Class 300 on alloy casings, only.

• Casing drain connection standard.

IMPELLER

• Closed type, one piece construction

• Manufactured with carbon fiber filled ETFE fluoropolymer.

• Magnets fully encapsulated by ETFE fluoropolymer.

• Replaceable, press fit main bushing, either carbon/graphite or sintered silicon carbide.

• Replaceable, mouth ring, either carbon fiber filled PTFE or sintered silicon carbide.

• Optional glass fiber filled PFA.

SHAFT

• Non-rotating, 1.25" (32 mm) diameter.

• One piece, solid construction, sintered silicon carbide (SiC).

• Fully supported at both ends utilizing front shaft support and containment shell.

• Axial groove for improved lubrication and particulate bypass. U.S. Patented.

Loading...

Loading...