1-GENERAL REMARKS

1-1 Power source features

This series machines include ARC and TIG types, with different specifications of rated current: 315A, 400A, 500A, 630A,

1000A, 1250A etc., which are high-efficient and energy-saving DC Arc welding machine. Enjoy reasonable static

characteristic and sound dynamic characteristic and HF arc starting function (this HF arc starting function is for TIG series

only).

Features and benefits:

- Strong ability against power grid fluctuation and arc length change. Strong capacity of arc self-adjustment.

- Soft switch technology, high efficiency.

- High duty cycle, small size, light weight.

- Continuous adjustment of welding current with wide range.

- Less spatter, high deposition rate, less welding deformation, pretty weld formation.

- Suitable for long distance welding, up to 50 meters.

- Digital display for accurate parameter preset.

- Easy arc-start.

- Wire/ Wireless remote control.

- 2 step/ 4 step (TIG series only)

- Two arc starting methods (contact arc starting and HF arc starting) to choose; with current down-slope function when

stopping arc, and the down slope time is continuous adjustable. (TIG series only)

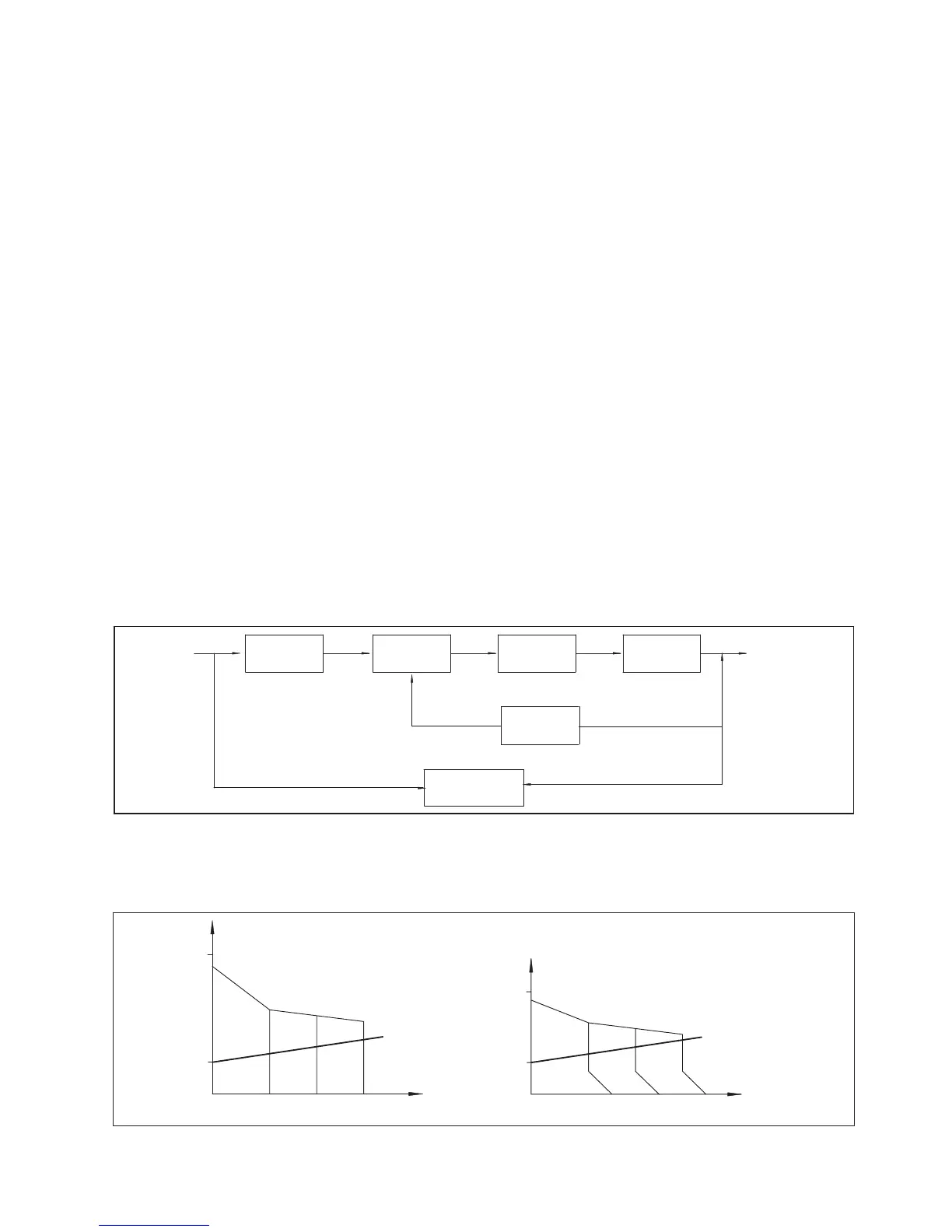

Fig. 1-2-1: Schematic diagram

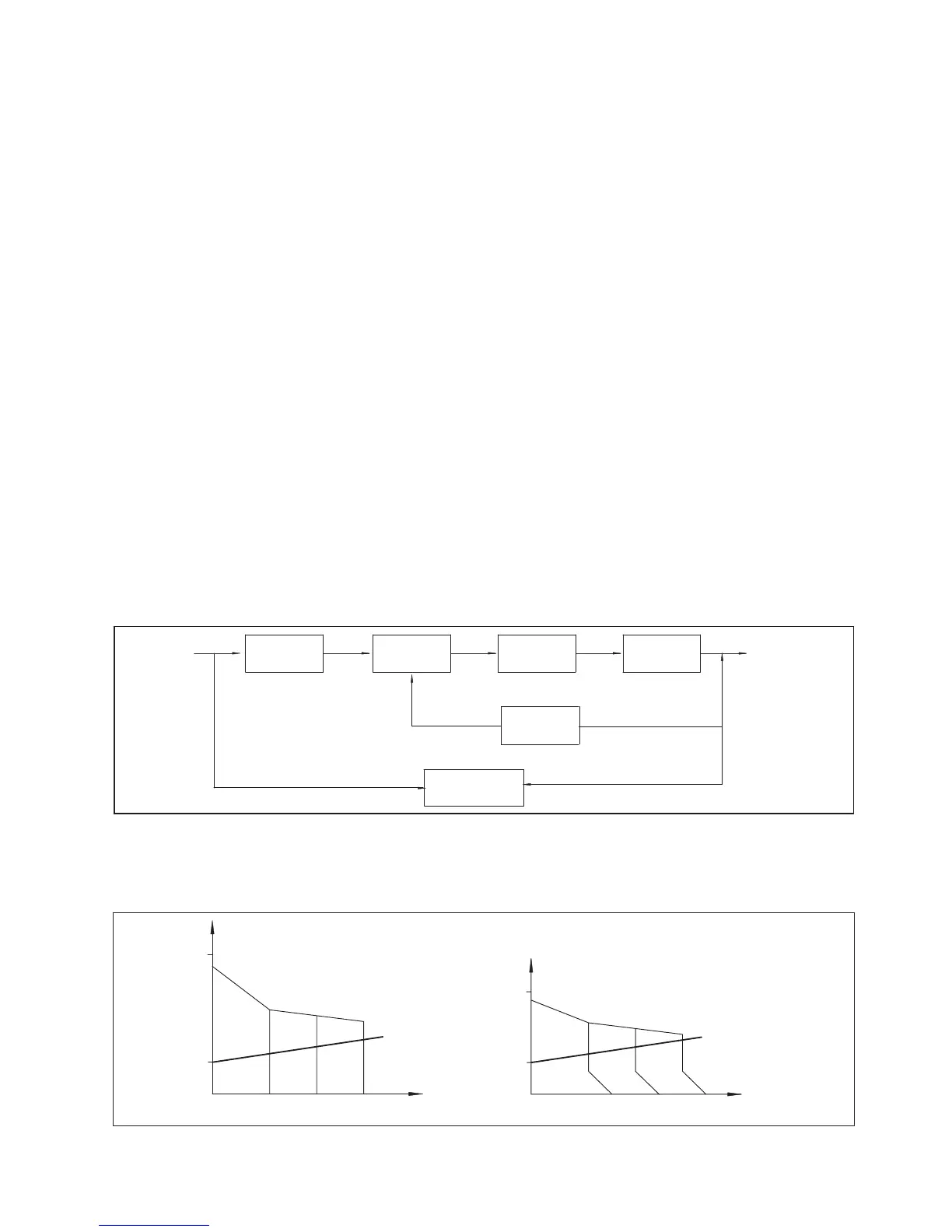

1-3 Output characteristics

Please refer to Fig. 1-3-1 for output characteristics.

Fig. 1-3-1: Output characteristics

3

1-2 Functional principle

This series welding machines apply IGBT soft switch inverter technology. 3- phase input volt are rectified by rectifier,

inverted into HF AC, reduced by HF transformer, rectified and filtered by HF rectifier, then output DC power suitable for

welding. After this process, the welding machine dynamical responsive speed has been greatly increased, so the size and

weight are reduced noticeably result in energy saving. Power source enjoy sound anti-fluctuation ability and high quality

performance during external context changes (such as fluctuation in input power supply and extended welding cables). The

schematic diagram (ARC series welding machines do not have HF Arc-starting device) is as shown in Fig. 1-2-1:

0

I(A)

U(V)

90

10

U=10+0.04I

Imin Imax

0

U=20+0. 04I

I(A)

U(V)

90

20

Imin

Imax

Input

Output

HF transformerHf inverte r

Rectifier an d filt er

3 pha se rect ifier

Control ci rcuit

Hf arc st arting

(only fo r TIG se ries)

TIG mode

SMAW mode

Loading...

Loading...