25

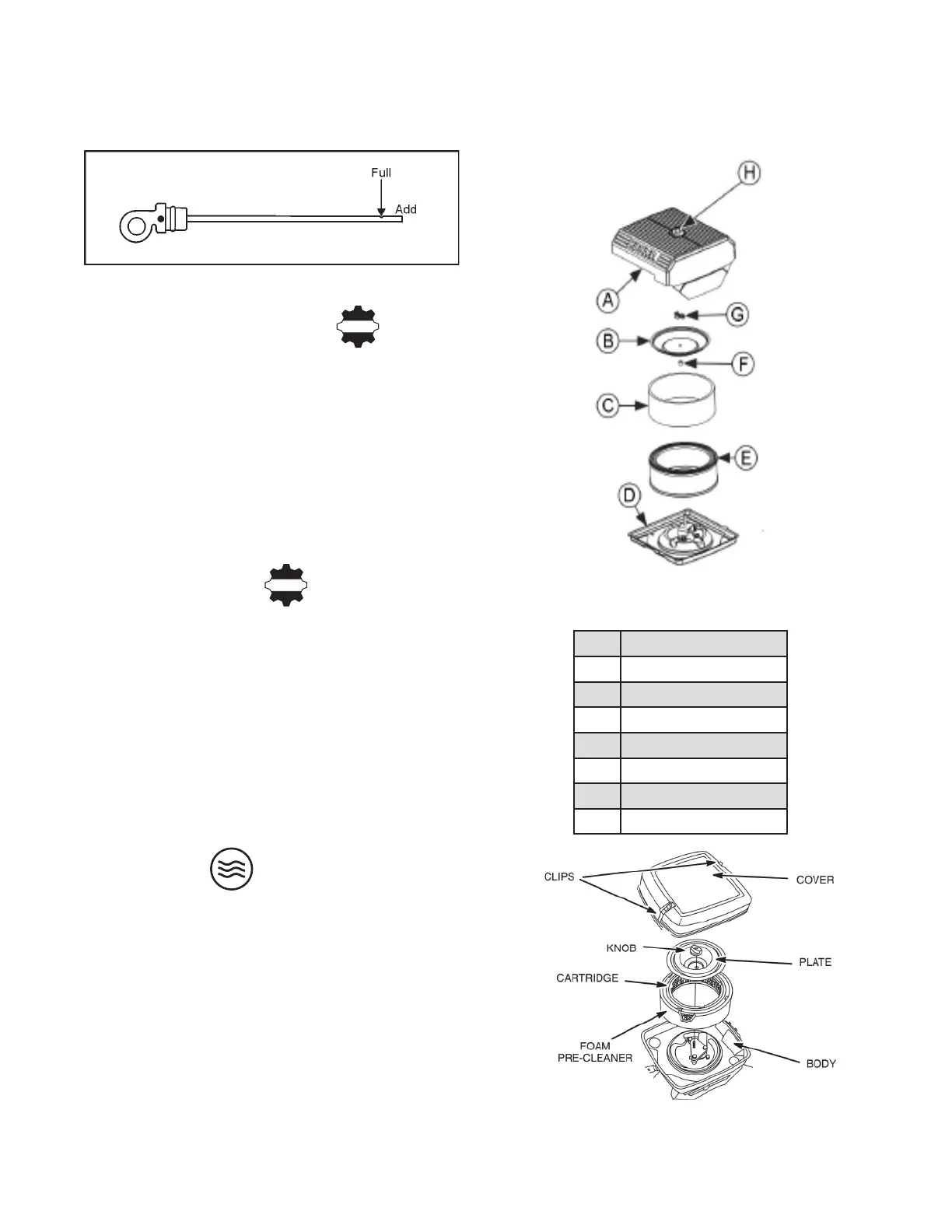

Figure 6-5. Kohler EFI Command

A Air Cleaner Cover

B Element Cover

C Precleaner

D Air Cleaner Base

E Air Filter

F Rubber Seal

G Wing Nut

H Cover

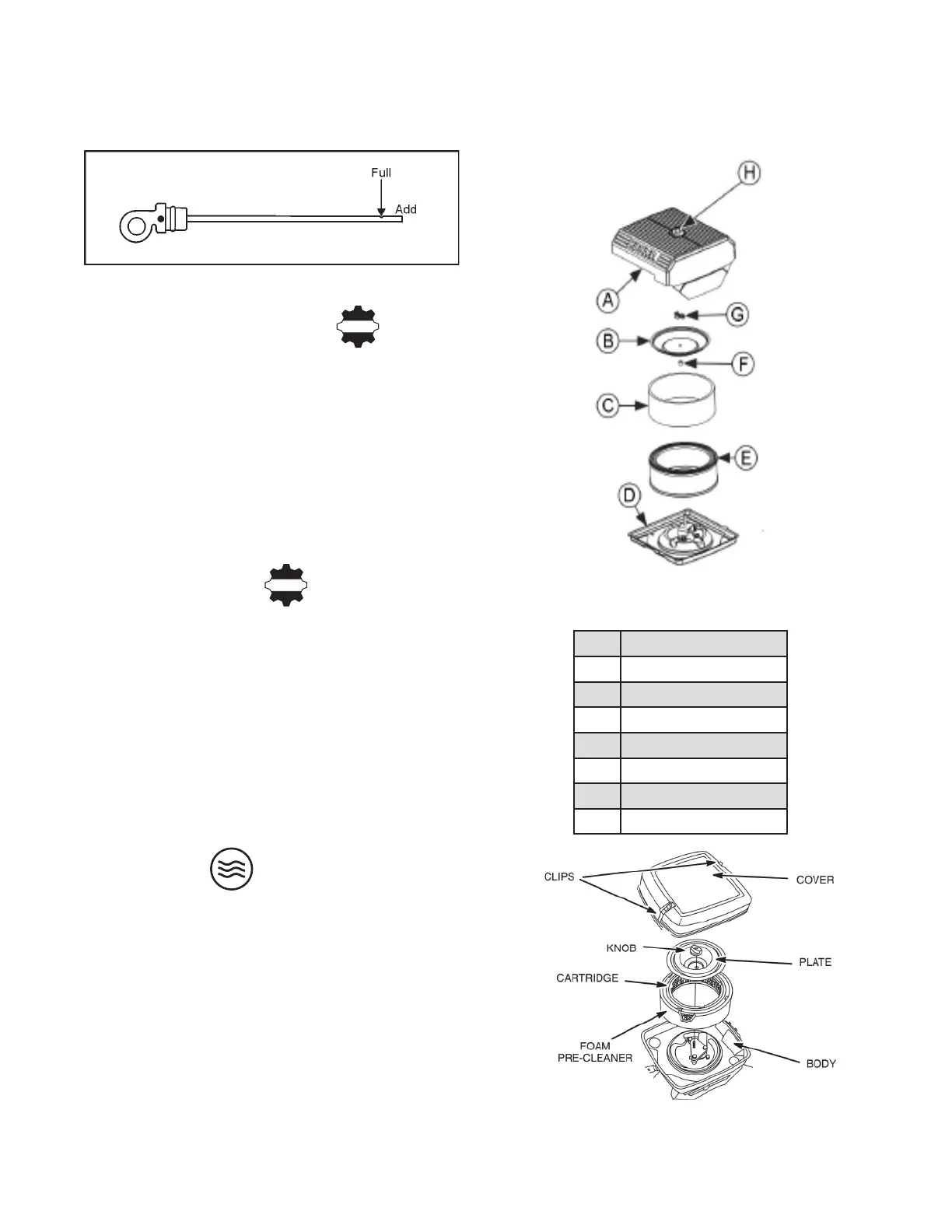

Figure 6-5a. Briggs amd Stratton Vanguard

Figure 6-4. Transmission dipstick.

6.2.2 Changing the Transmission Oil

CLA

Changethetransmissionoilaftertherst20hoursofoperation.

After this, change the transmission oil every 100 operating

hours.Removerewalltoaccessthedrainpluglocatedatthe

bottom of the transmission. Drain the transmission oil into

a suitable container and dispose of the oil at a disposal site.

Whiledrainingthetransmissionoil,besuretocleanoany

metal particles that are on the magnet of the drain plug. These

nemetalparticlesarearesultofthetransmissiongearsmesh-

ing during the initial break-in period. Re-install the plug and

tighten it securely.

Relling the Transmission

CLA

Rellthetransmissionthroughtheoilll/dipstickhole.Use

80W 90 Gear Lube (GL5 Rated) or ARGO brand 75W90 Syn-

theticlube(PartNo.130-104).Asyourellthetransmission,

check the oil level with the dipstick. Check that the oil level

is even with the mark on the dipstick, after it has been seated

fully in the dipstick hole. DO NOT OVERFILL.

Overllingmayresultinoilbeingforcedoutthebreatherhole

that could contaminate the brake pads and lead to brake failure.

Transmission Oil Capacity: 1.1 L (1.1 qts.)

6.3 FILTER INFORMATION

6.3.1 Air Filter

AllKohlerCommandProEFIengines(gure6.5)andBriggs

andStrattonVanguardengines(gure6.5a)areequippedwith

afoamprecleaneranddrypaperairlterelementhousedinan

air cleaner assembly attached to the throttle body/carburettor.

Replace or wash precleaner in warm water with detergent.

Rinse and allow to air dry. Saturate precleaner with new en-

gine oil; squeeze out excess oil. Replace the paper element.

Wash and oil the precleaner after every 25 hours of operation

or more often under extremely dusty or dirty conditions.

Checkthepaperairlterelementevery100hoursofopera-

tion or more often under extremely dusty or dirty conditions.

SECTION 6

OIL, FILTER AND LUBRICATION INFORMATION

Loading...

Loading...