8

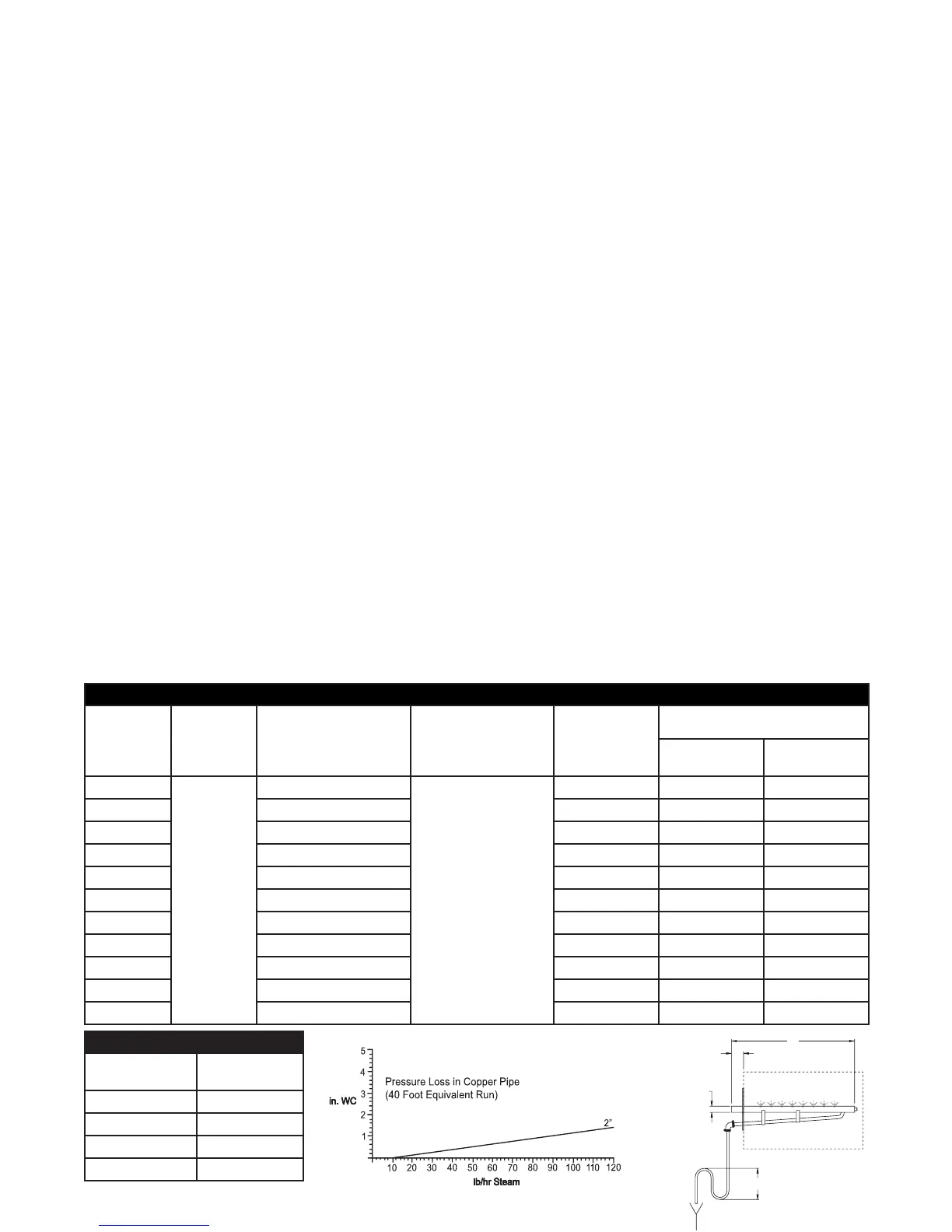

Table 8-1. Dispersion Tube Length

Model

HC6100,

HC6100DI

Model

HC6100,

HC6100DI

“D” Dia.

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700DI

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700 DI “DL” Dia.

Steam Disp. Tube

Length “L”

mm (in)

Duct Width

Minimum

mm(in)

Maximum

mm (in)

D-1

1-1/2”

DL-1

2-3/8”

305 (12) 280 (11) 406 (16)

D-1.5 DL-1.5 457 (18) 432 (17) 559 (22)

D-2 DL-2 610 (24) 584 (23) 864 (34)

D-3 DL-3 914 (36) 889 (35) 1168 (46)

D-4 DL-4 1219 (48) 1194 (47) 1473 (58)

D-5 DL-5 1524 (60) 1499 (59) 1778 (70)

D-6 DL-6 1829 (72) 1803 (71) 2083 (82)

D-7 DL-7 2133 (84) 2108 (83) 2388 (94)

D-8 DL-8 2438 (96) 2413 (95) 2692 (106)

D-9 DL-9 2743 (108) 2718 (107) 2997 (118)

D-10 DL-10 3048 (120) 3023 (119) 3302 (130)

Duct Steam Distribution

1. The dispersion tube should be proper length. Verify correct size from Table 8-1.

2.Installdispersiontube(s)horizontallyinductsoholesfaceupward.Airflowmustbeverticalupor

horizontal.Donotrestrictductwithaheightof200mm(8”)orless.Installationsover10m/s

(1800FPM)airvelocityarenotrecommended.Consultfactoryifairflowisverticaldownorair

velocityisover10m/s(1800FPM).Donotinstallinductedsystemswithstaticpressureexceeding

150mm(6”),wc.Airflowshouldbeaminimumof250FPMforinstallationsusingdispersiontubing.

Consult factory if velocity is below recommended level.

3.Thedispersiontube(s)shouldbelocatedupstreamofastraightductrun,withoutobstructions,3m

(10feet)ormoreinlength.Consultthefactoryifthisdistanceisnotavailable.

4. Use the template provided to cut dispersion tube installation holes. Fasten the mounting plate to

ductwithsheetmetalscrews.Ifthedispersiontubeis900mm(35”)orlonger,supportthefar

end with threaded rod or similar means.

5. Note:Forsteambeinggeneratedfromadeionized(DI)orreverseosmosis(RO)watersource,the

useof50mm(2”)insulatedstainlesssteelpipinginlieuofcopperisrequired.Pipeusedforsteam

dispersion piping must be oil and contaminate free. Premature element failure could result if oils or

contaminatesarepresent.Contactthefactorywithquestions.Connectdispersiontube(s)to

HumidiCleantankusing50mm(2”)nominalinsulatedcopperpipeandhosecuffsprovided.Wedo

not suggest steam distribution piping of field supplied rubber based compounds to be used for any

HumidiCleanapplication.Pitchpipebacktounit25mm(1”)perfoot.Thesteampipemustbefree

of kinks and sags to allow for gravity drainage of condensate. Maximum pipe run distance from

tanktodispersiontubeis12m(40feet)equivalentpipinglength.Avoidexcessiveuseofelbowsor

45°changesindirection.A“P”trapshouldbeinstalledevery6m(20feet),ofpipingrunorat

the bottom of vertical runs that cannot drain back to the tank. See Fig. 5-1 or 5-2 for piping detail.

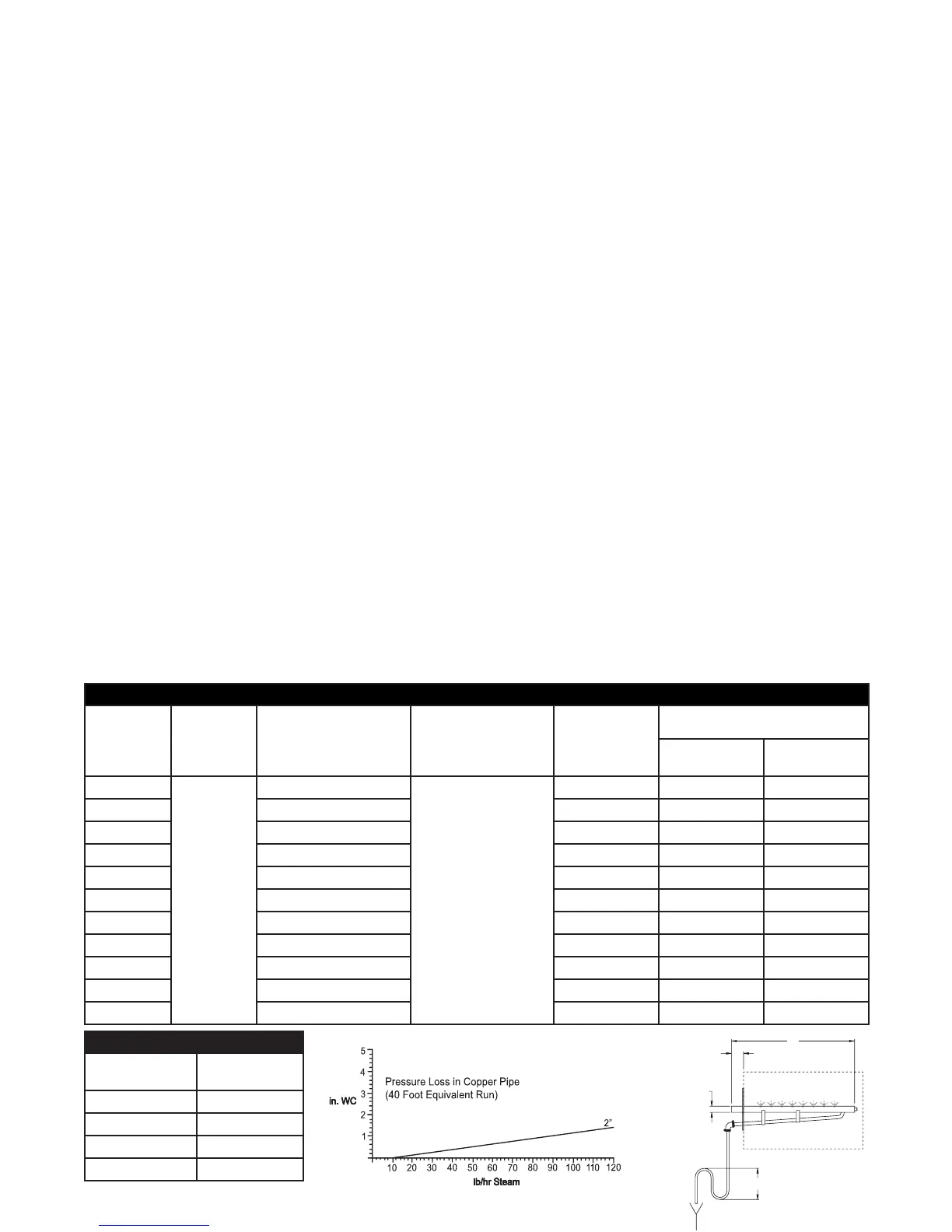

6.Ifductstaticpressurepluspipingbackpressureisgreaterthan0.5inHG(6”WC),pleaseconsult

thefactory.(SeeFigure8-1forbackpressureinpiperun.)

D

2

L

6" Min. Water Seal

Figure 8-2

Figure 8-1

Table 8-2.

Fitting Style

Equivalent Linear

Piping (feet)

2” - 45° Elbow 2.8

2” - 90° Elbow 5.5

2” - 90° Long Elbow 3.5

2” - Tee 12

Loading...

Loading...