9

Area Steam Distribution

TheEHF-3fanpackage(minimumof2requiredforHC-6500/6700)isdesignedtobehungonawall

to operate as a remote mounted, direct area discharge option. It incorporates a blower rated at 120v-

1.28 amps. CFM rating is 463 @ 1600 RPM. The fan package requires a separate 120 volt power sup-

ply(optionalstepdowntransformeravailable).ConsultArmstrongInstallationBulletinIB-95formore

information.

Alternative for shortened non-wettable vapor trail

For applications with particularly limited downstream absorption distance, Armstrong HumidiPack or

ExpressPack may be considered. HumidiPack is a prefabricated separator/header and multiple dis-

persion tube assembly. ExpressPack is a multi-tube steam dispersion panel which is shipped unas-

sembled. The Armstrong HumidiPack or ExpressPack provide uniform distribution and shortened non-

wetting vapor trail. Consult Armstrong Installation Bulletin No. 560 or Bulletin 573 for more information.

Control Wiring

When knock-out for sensor wiring is removed, an IP65 compliant cable bushing will be required to

keep the electric cabinet in compliance with IP32.

Wiring for low voltage controls should not be run in same conduit as the power supply. Use of shielded

wire or a separate dedicated metal conduit is required. When shielded cable is used, shield is to be

groundedatthehumidifieronly.Thewireshouldnotbelongerthan30meters(100ft).Ifthewireis

out of this limit, please contact Armstrong. Refer to Figures 10-1 and 10-2 for wiring schematics.

Control Humidistat

1. Locate control humidistat where it will sense the average air condition of the space to be

humidified. Avoid areas of restricted circulation or locations where the sensor will be

subjected to drafts, localized heat or moisture sources.

2. Optional duct mounted humidistats are available to sense return or exhaust air, if

preferred.

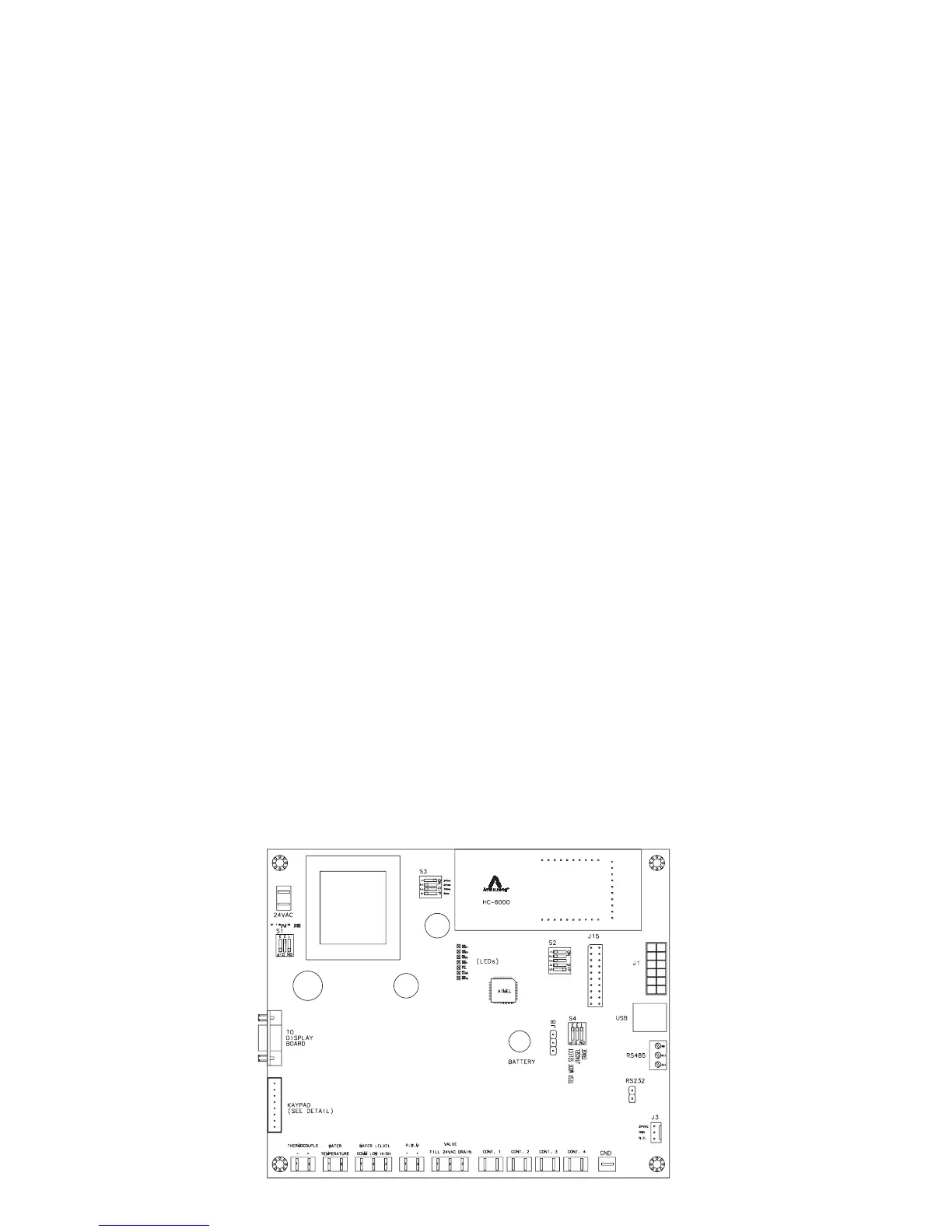

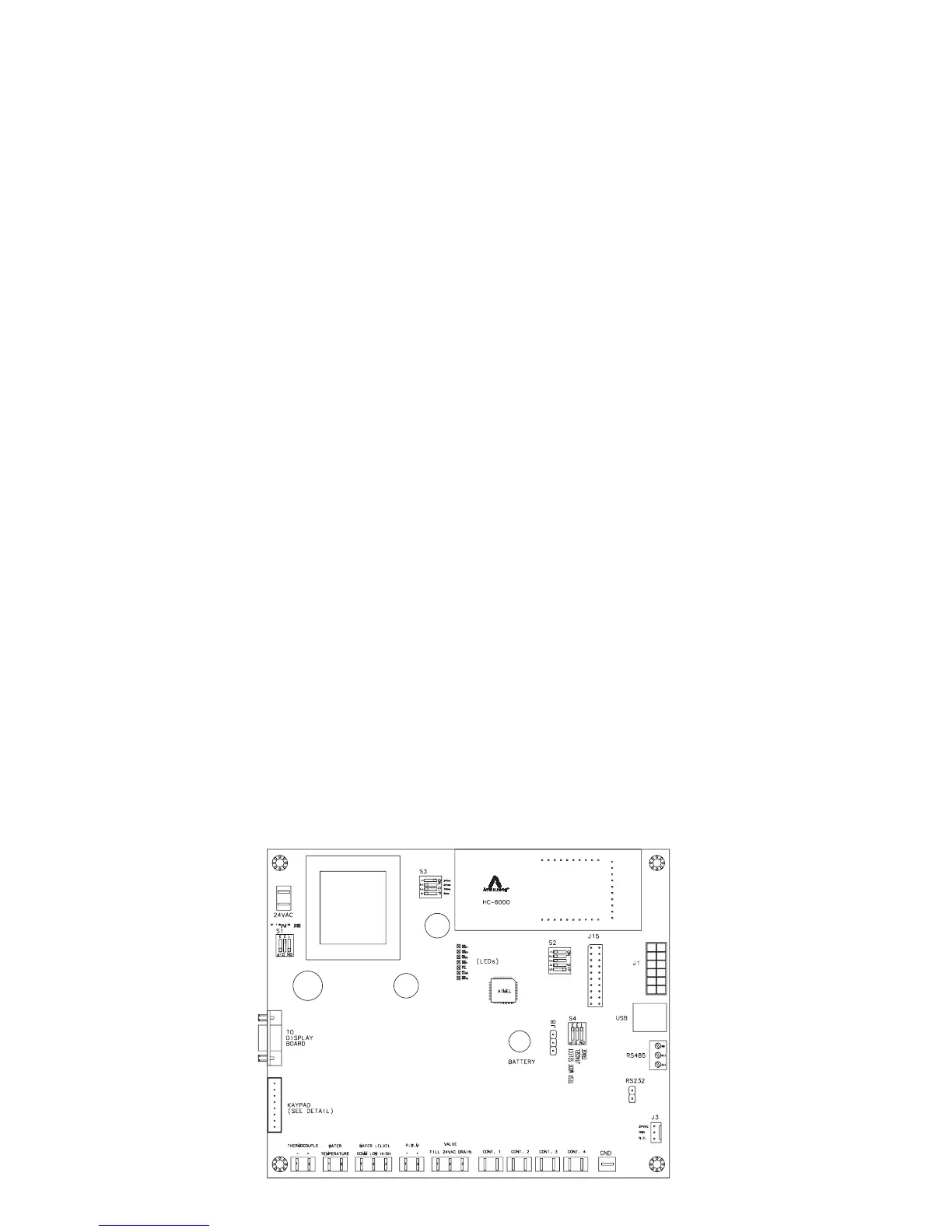

3. Set DIP switch S-2 on the PC board to the proper range for the humidistat control signal to be

used.SeeFigure9-1.AlsosetvoltagesourceDIPswitch(S1andS3)toproperrange.See

Fig. 9-1 for location of switches and pages 10 and 11 in tandem with the applicable wiring diagram

below for correct switch settings.

Figure 9-1

Loading...

Loading...