3 of 8

DOOR

FRAME

TOP OF

DOOR FRAME

DOOR

1

A – C/D Drill holes

3

2

Attach the Template and

Mark the Drill Holes

1 SELECT a mounting location for the

Magnalock and strike assembly.

NOTE: The edge of the template should be about 1" [25.4 mm]

from the latch side of the door to allow proper access

at the mounting locations for drilling and tool access.

2 ATTACH the template to the door and

frame (as shown in Diagram 4).

• IF Installing a strike plate horizontally,

THEN ENSURE the top edge of the strike

will be approximately 1/8" [3.2 mm]

below the door frame stop.

• IF the strike and magnet are to be mounted

VERTICALLY, THEN INCREASE the clearance

between the strike and frame to 3/16" [4.8 mm].

3 WHEN the template is attached, THEN MARK the

location of all holes to be drilled using a center punch.

Drill Holes for the Lock

Body and Strike Plate

1 DRILL Holes #1 and #3 (see Diagram 5) with

3/8" [9.5 mm] diameter without bushings OR

1/2" [12.7 mm] diameter with bushings,

and 1" deep into door.

2 DRILL Hole #2 (see Diagram 5) with 3/8" [9.5 mm]

diameter thru the door, and 1/2" [12.7 mm]

diameter from other side for sex bolt.

3 DRILL holes per template, in door frame, 3/8" [9.5 mm]

diameter for the installation of the lock body blind

nuts. OR 3/16" [5 mm] diameter without blind nuts.

NOTES: Use a pilot hole, then drill to final size for

an accurate hole diameter and placement.

4 INSTALL the Blind Nuts (see Diagram 6).

5 INSERT the assembled blind nut and installation

tool into a 3/8" [9.5 mm] mounting hole.

6 HOLD the install nut using a 1/2" [13 mm]

box-end wrench and, at the same time,

COLLAPSE the blind nut using a 3/16" [5 mm]

hex wrench to turn the socket cap screw.

NOTE: The collapsing tool is reusable for

several blind nut installations.

7 REMOVE the collapsing tool when finished.

NOTE: Once installed, the blind nuts leave a

threaded insert that will accept the machine

screws provided in the hardware pack.

8 VERIFY that the blind nut is properly collapsed.

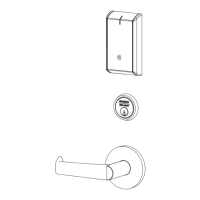

Diagram 4 Attaching the Template

Diagram 5 Drill Holes

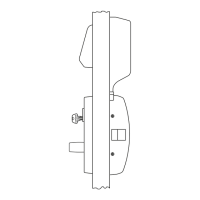

BLIND NUT

INSTALL NUT

SOCKET CAP SCREW

HEX (ALLEN) WRENCH

TURN

WRENCH HOLD

FLAT WASHERS (X2)

STAR WASHER

Blind Nut

AFTER Collapse

Blind Nut

BEFORE Collapse

Diagram 6 Blind Nut

Loading...

Loading...