21

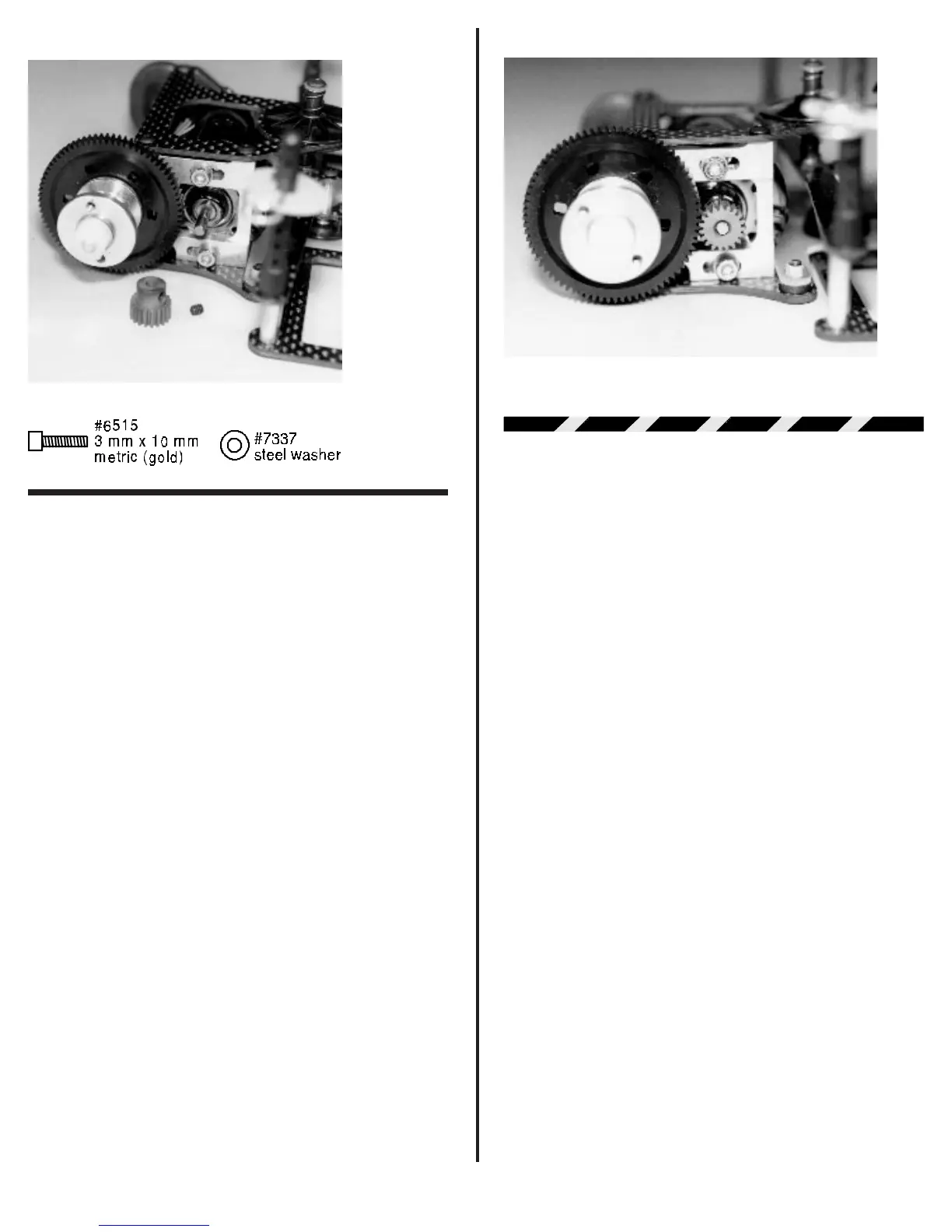

Fig. 73

❑ Fig. 74 Now we need to set the gear mesh. This is

accomplished by moving the motor forward or back. This

moves the pinion gear closer to or further away from the spur

gear. What we want to accomplish is to get the metal pinion gear

as close to the spur gear as possible, but without binding the

gears. The easiest way to check this is to put your finger on the

nylon spur gear. See if you can rock the spur gear teeth back

and forth (lightly) between the pinion gear teeth without making

the pinion gear move. We want the gears meshed as close as

possible but still have the ability to rock the spur gear. When you

have the spacing correct you can tighten down the two #6515

3mm screws. Now recheck the gear mesh to make sure nothing

moved when you tightened down the screws. It is important to

keep in mind that a tight gear mesh will result in a high power

loss. A loose gear mesh can result in stripping off the spur gear

teeth. So take your time.

WARNING! The gold colored motor

screws are metric. The coloring was done to prevent

mixing up the motor screws with the standard black 4-40

screws used in the rest of the kit. Accidentally using the 4-

40 screws in the motor will strip out the mounting holes in

the motor can. This damage to the motor can cannot be

corrected except by replacing the motor.

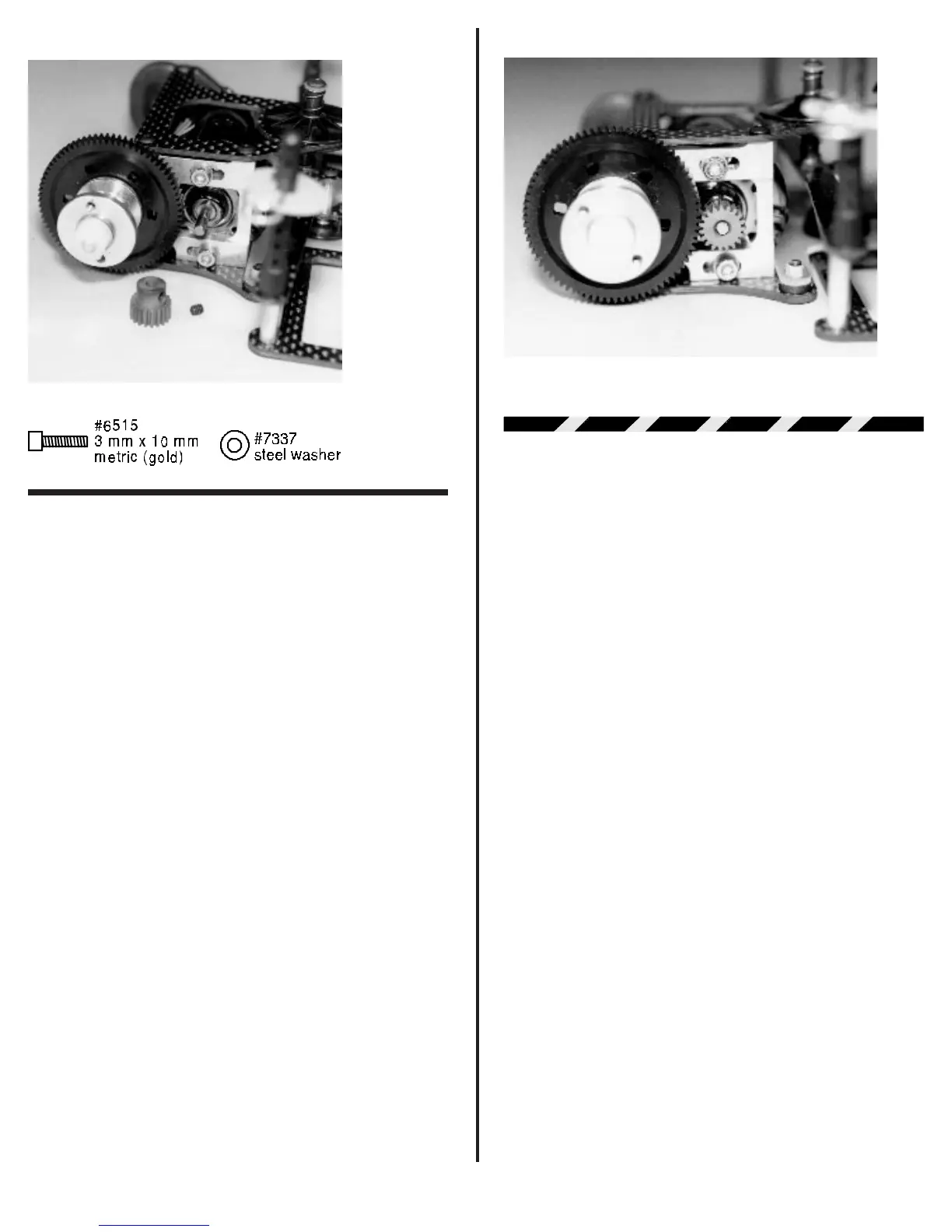

Fig. 74

STEERING SERVO & TIE-ROD

ASSEMBLY

Most radio systems come with standard medium size

servos. Because of space limitations a medium servo will not

fit. The stock servo mounting holes will accept the following

servos that we have been able to test.

Airtronics Futaba

94143 S-32H/S-32SH

94144 S-132H/S132SH

94145 S-9601

94831

If you have a servo not listed here, make sure it fits

before you try to install it. Other servos may fit, but also may

require drilling new mounting holes in the chassis.

Note: We only supply one servo saver with the kit.

As a random choice we have included the Airtronics servo

saver. If you have a Futaba servo or other brand you will

have to purchase the correct servo saver.

❑ Figs. 75 & 76 Go back and take out bag #1 that we

set aside early in our assembly. From this bag remove the two

#8435 molded steering servo mounting blocks. The drawing

below shows which holes to use with the different size servos.

Now determine which mounting holes are correct for your

servo. Take out your drill motor and #43 drill bit. (Remember if

you could not find a #43 drill bit a 1/8” bit will work if you are very

careful). Drill the correct two holes in each mount for your servo.

Make sure the hole is perpendicular to the mounting face of the

servo mounting block.

Next remove the #3760 Airtronics servo saver, two

#4448 aluminum ball ends, and two #4449 4-40 small alumi-

num locknuts (also in bag #1). Please remember if you have a

Futaba or another brand of servo you will have to purchase the

correct servo saver. The photo shows the eight holes in the

servo saver. You will need to drill out the top two holes (one on

each side). We want the balls to be as close to the servo horn

Loading...

Loading...