22

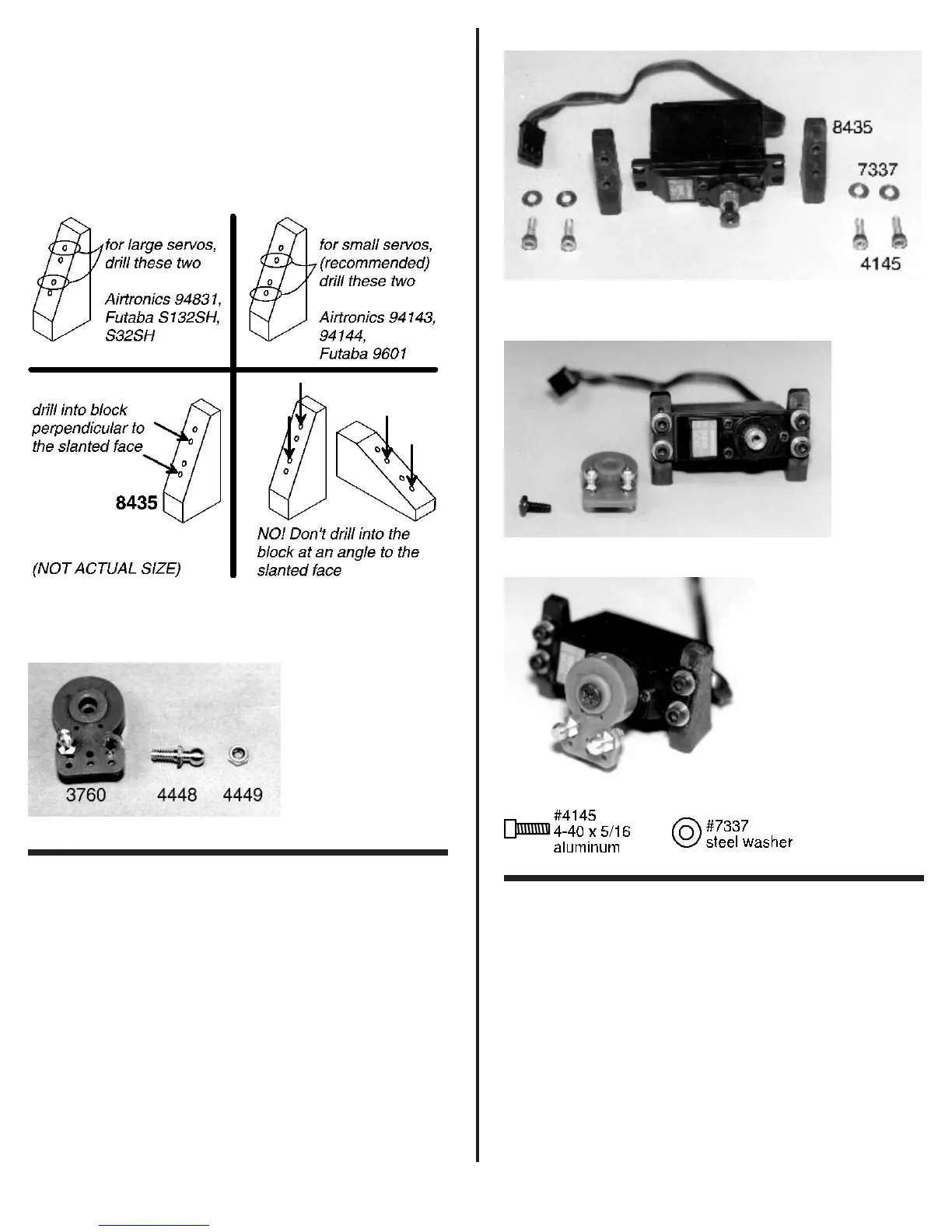

pivot point as possible. Use your #34 drill bit, or your 3/32” if you

cannot find a #34 bit. After you have drilled out the holes install

the two #4448 ball ends into the servo saver and thread the two

#4449 locknuts onto the ends of the threads.

WARNING! The

ball ends should just be able to slide through without

threading. The holes are close enough to the edge of the

servo saver they could crack through if the ball ends were

threaded in.

Fig. 75

Fig. 76

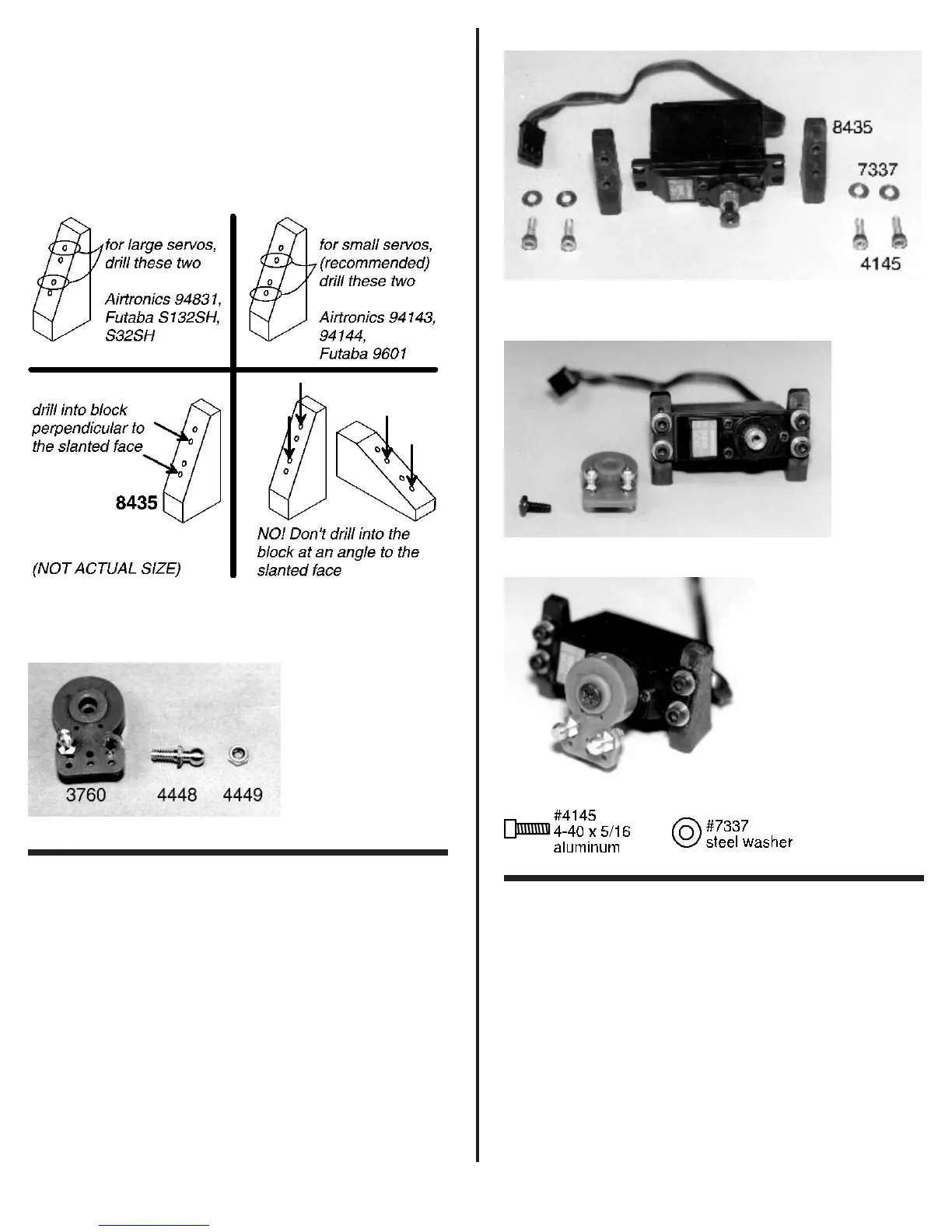

❑ Figs. 77, 78 & 79 Remove the four #4145 4-40

x 5/16” aluminum SHCScrews and four #7337 servo washers

(small gold colored) from bag #1. Use the #4145 screws and the

#7337 washers to secure the two #8435 servo mounting blocks

to the servo.

Now remove the stock servo horn, if one came on your

servo, and install the servo saver. We want the servo saver to

be pointing down. Now check the throw of the servo saver in

both directions. If it does not have the same travel in both

directions, remove the servo saver and rotate it's starting

position one or more splines and then reinstall it. Go ahead and

secure the servo saver with the stock servo horn screw (for

metal gear servos) or the screw that came with the servo saver.

With the servo output shaft facing you, make sure the output

shaft it to your right side. Your completed servo should look like

fig. 79.

Fig. 77

Fig. 78

Fig. 79

❑ Fig. 80 In bag #1 you will find two #6292 4-40 x 3/8”

FHSScrews. We will use these to secure the servo mounts to

the chassis. The holes for mounting the servo to the chassis are

spaced so that the most popular Airtronics or Futaba servos will

fit. You may have to adjust the placement of the #4145 screws

in the mounting locations but this is all that should be required.

If you are running a different brand of servo you may have to drill

new holes if the existing ones do not line up correctly. Use the

two #6292 screws to secure the servo to the chassis as shown.

Loading...

Loading...