23

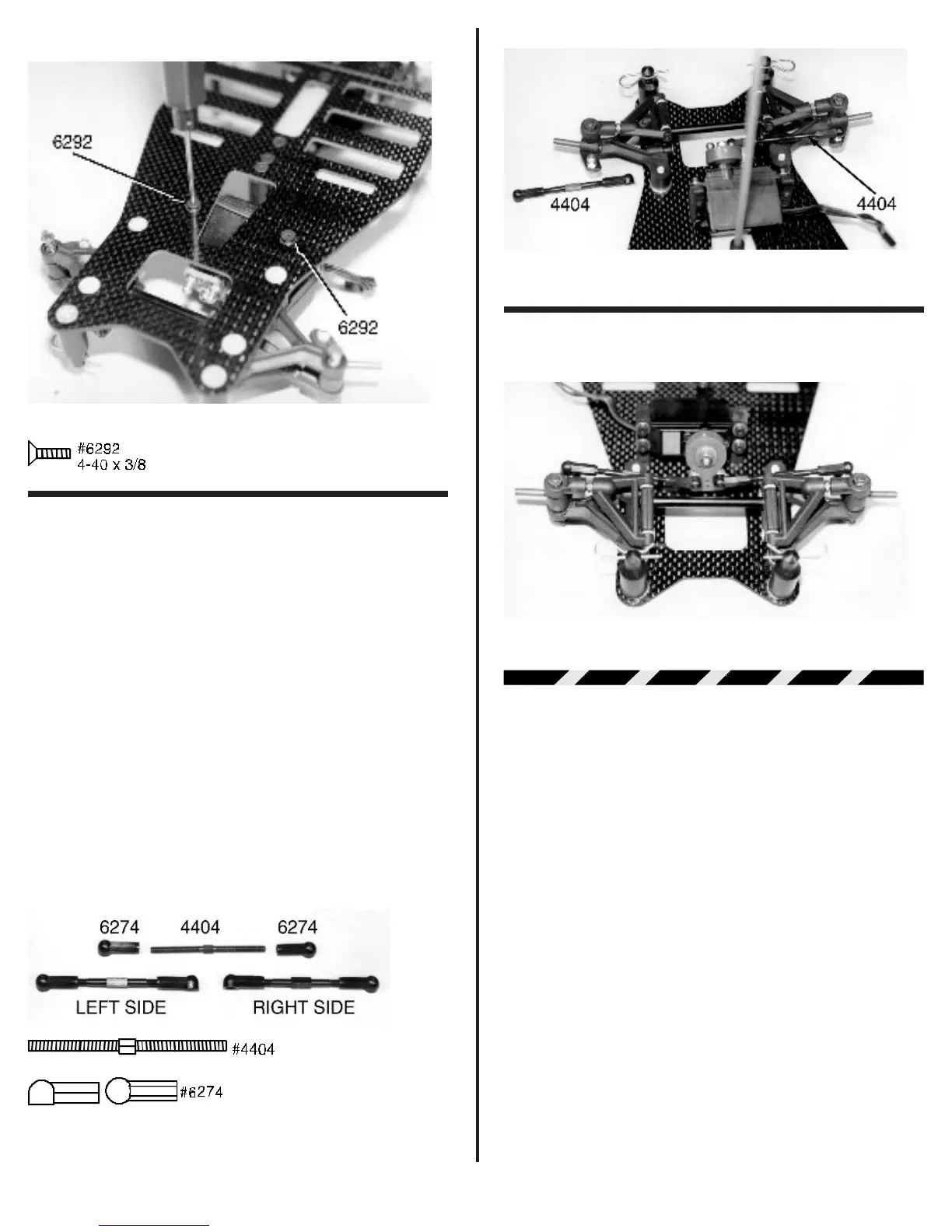

Fig. 80

❑ Figs. 81 & 82 Now we need to take out the two

#4404 turnbuckles and four #6274 plastic ball end cups. Screw

one #6274 plastic ball end cup onto the end of each turnbuckle

evenly. The turnbuckles have left hand threads on one end and

right hand threads on the other end. This means the ball end

cups will thread on in opposite directions. Adjust the ball end

cups until you reach an adjusted length of about 2 3/16” (about

55.5mm or 2.18”). All measurements are done from the

center of the ball cup hole to the center of the opposite ball

cup hole. Because the servos may place the output shaft in

slightly different positions you will have to fine tune the front toe-

in after everything is installed. Notice the difference in the

direction the ball cups face on opposite ends of the same

turnbuckle. Also the right and left turnbuckles will be facing ins

opposite directions as shown in fig. 81.

Snap the assembled turnbuckles onto the steering

block ball ends and the servo saver ball ends. It will be best to

do this with your needlenose pliers. Remember there is a right

and a left hand turnbuckle. You can adjust the front toe-in now

or wait until the final adjustment section at the back of the

manual.

Fig. 81

Fig. 82

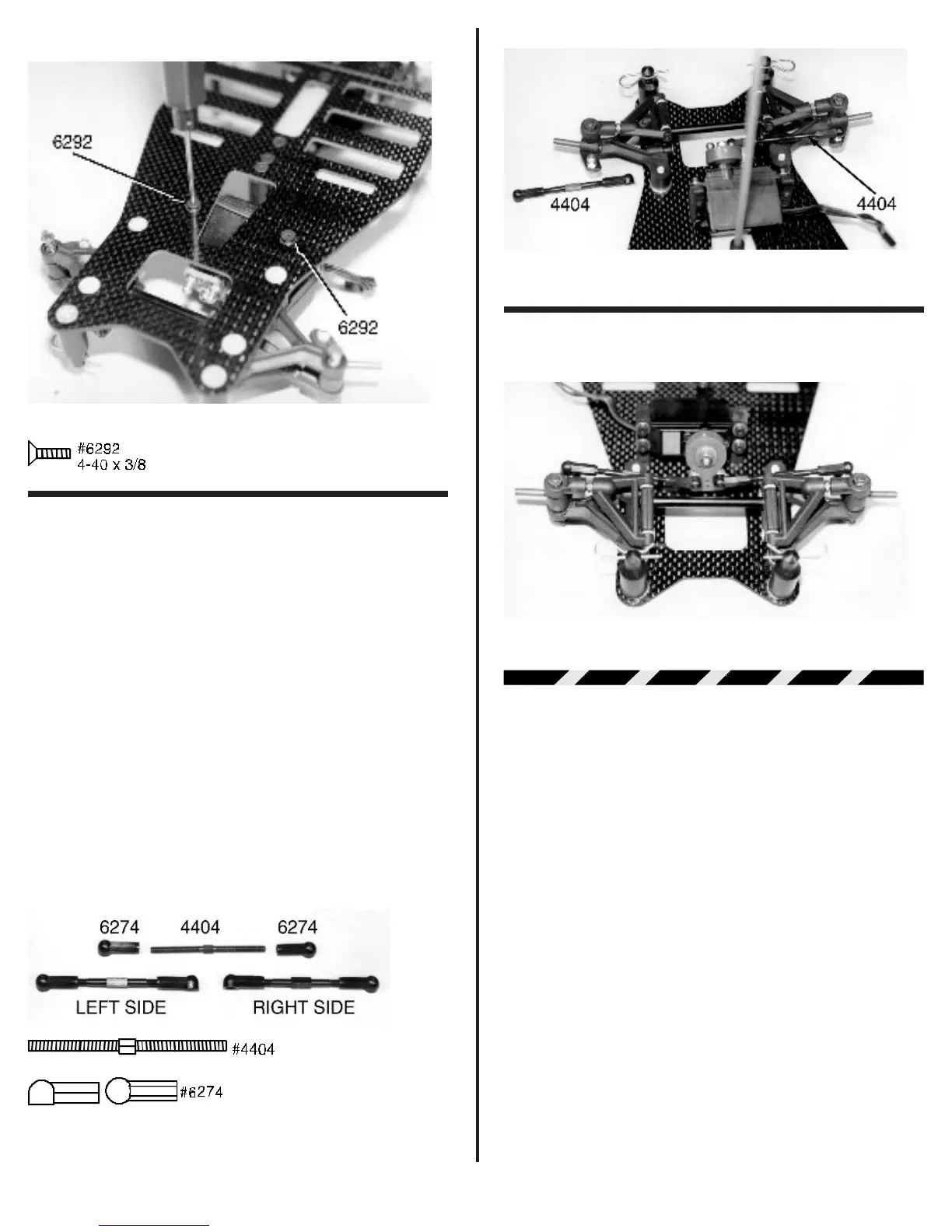

❑ Fig. 83 Your completed front suspension with steering

servo should look like this.

Fig. 83

BATTERY ASSEMBLY &

INSTALLATION

Your new RC12LC is setup to run four or six cell saddle

type battery packs. Some companies offer these in pre-as-

sembled packs but most people will have to assemble their

own. The following steps will show you the correct way to

assemble a six cell saddle type battery pack if you do not

already know how.

❑ Figs. 84 & 85 Make sure you use ROSIN core

solder, the preferred being the more popular 60/40 variety. DO

NOT use acid core solder. This can damage your electrical

components and connections. Fig. 84 shows the right or

passengers side of the battery pack. Fig. 85 shows the left or

drivers side view of the same battery pack. The cells are

soldered in series. This means the positive end of the first cell

will be soldered to the negative end of the second cell, and its

positive end be soldered to the negative end of the third cell and

so on. In between the third and fourth cell the connection will be

made by a jumper wire. This wire has to be long enough to reach

across the gap between the slots in the chassis and to be able

to clear the T-bar. Normally we use 16 or 14 gage wire for this

connection.

Loading...

Loading...