In front of the installation place of PBD, a space of 1.5m or more shall be ensured, the back 0.8m

or more, the top 0.8m or more to ensure easy installation, cooling and maintenance.

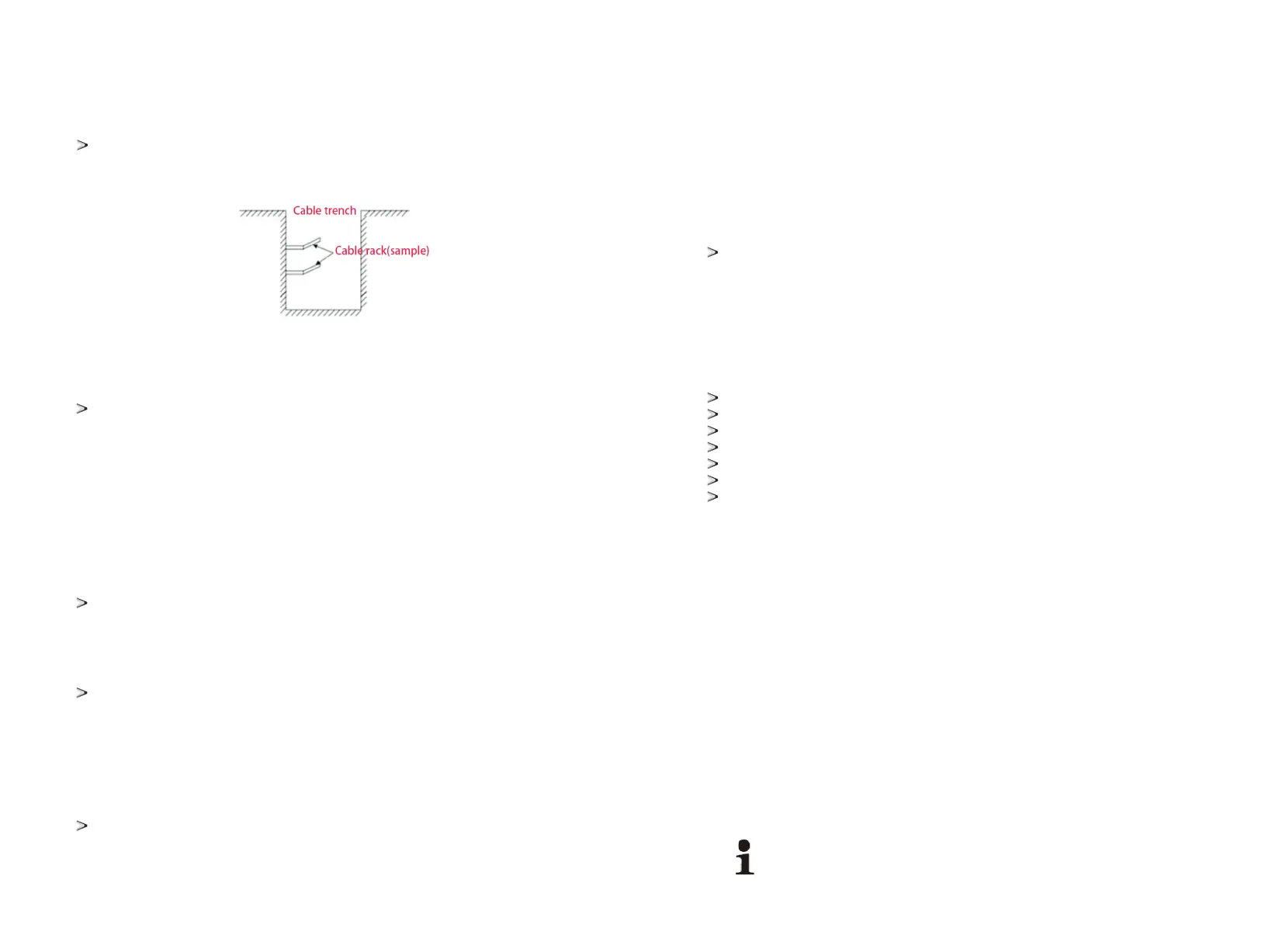

Cable trench

The cable connection of PBD adopts bottom inlet and bottom outlet. Cable trenches are

recommended to ensure easy installation and maintenance.

The cable trenches are often designed and constructed by the construction side based on relevant

standards, with the equipment weight and dimensions required to be considered. Good electrical

connection is needed between different cable trenches and GND terminals.

Wiring specification

Cables in the PBD can be classified into either power cables or communication cables. In cabling, the power

cable shall be kept far away from, and the cable shall be kept in right angle at cross. The cable shall be as

short as possible, and an appropriate distance shall be kept to the power cable. The insulation impedance

of Bt + and Bt - at DC end to ground is recommended to be greater than 1 Ω.

The power cable and data access shall be placed in different cable trenches respectively to avoid lengthy

routing between the power cable and other cables, so as to reduce the electromagnetic interruption caused

by sudden change of the output voltage. The distance among the power cable and data access shall be

more than 0.2m. When the cables are crossed, the cross angle shall be 90 degrees, while the distance can

be reduced appropriately.

Ventilation requirement

In operation, PBD will produce a lot of heat. When ambient temperature is too high, the electrical property

of the equipment may be affected, the equipment may even be damaged. Therefore, the heat release shall

be fully considered in designing the control room to ensure operation of the equipment in high efficiency.

Ventilation environment

To satisfy the ventilation requirement of PBD, its installation environment shall meet the following

conditions:

※ PBD shall be prevented from being installed in the place of poor ventilation condition and insufficient air

flow;

※ The air inlet shall have enough air supplementation.

Ventilation equipment

To ensure safe and reliable operation of the equipment, the ambient temperature must be within the

permission range –25°C~ 55°C, therefore, appropriate ventilation devices must be equipped with to release

the heat generated by the equipment. We suggest the ventilation rate be more than 3665m³/h.

1. There must be ventilation equipment inside the distribution room to ensure release of the waste heat

generated by the PBD from the equipment, and allow for maximum ambient environment temperature. This

can be realized from installation of exhaust devices;

2. Another fan can be added at the air duct outlet to exhaust the air out and ensure balanced pressure;

3. The direction of the air outlet shall be selected according to the local actual wind direction;

4. Pay attention to the dustproof measures and waterproof design at the air inlet and outlet;

5. If more air ducts are required, its dimensions shall be designed by the professionals according to the air

output amount.

Other protections

With IP20 of protection level, PBD is appropriate to be installed in dry and clean environment. Meanwhile,

water leakage of the house shall be prevented, as it may damage the PBD. According to EMC requirement

and noise level, the PBD shall be installed in industrial environment.

5.2 Tools and spare parts required for whole machine installation

Tools and spare parts required for installation is as follows:

Hoisting crane, forklift or fork lift truck (with the capacity for bearing the weight of the PBD)

Torque wrench

Screwdriver

Wire stripper

Terminal crimping machine

Heat dryer

Megger and multimeter

5.3 Mechanical installation

5.3.1 Transportation of packaged whole machine

This PBD is transported as an integrated unit, and the user can hoist it from the bottom with a forklift, or

move it with a hoisting crane or crane.

Note 1: The PBD is integrated and cannot be dissembled either in transportation or installation. Any fault

attributed to modification unauthorized by ATESS is beyond our warranty liability.

Note 2: In movement, tilt, violent shake or sudden force upon the PBD shall be prevented, such as sudden

down or lifting.

Note 3: Please read carefully the labeled parameters to select an appropriate transportation means and

storage place.

We suggest the user make use of forklift to move the PBD if possible.

Before the PBD is moved to the designated place, we suggest to lay the DC input cable and

AC main power supply cable. As these cables are relatively thick, they are hard to be cabled

after the PBD is installed.

15 16

Loading...

Loading...