Maintenance and modification

Only personnel authorized by ATESS can maintain and modify the PBD. To ensure personal safety, please

use only the original components provided by the manufacturer. Otherwise there will be no guarantee on

compliance with relevant certification standards in terms of electrical safety, EMC, etc.

Function and safety parameters

Do not change the parameters of PBD without the authorization of the local power supply company or

without the instruction of ATESS. Unauthorized change of functional safety parameters may cause injury

and damage to personnel or PBD, in which case, ATESS will not provide warranty services.

CAUTION!

1. After power on, wait for 5 minutes to confirm safety before carrying out maintenance

work.

2. Use multimeter to measure, ensure the safety before disassembling.

9.1.2

R

e

pla

ce the dus

t scr

ee

n

During the use of inverter, the dust on the top shall be cleaned regularly, and the dust screen at the air inlet

shall be cleaned or replaced. During the replacement of the dust screen, the inverter shall be powered off.

Replacement method of dust screen: The dust-proof filter cotton on the door panel can be directly pulled

up for cleaning and replacement.

In order to ensure the normal operation of inverter, it is necessary to clean the dust screen

regularly.

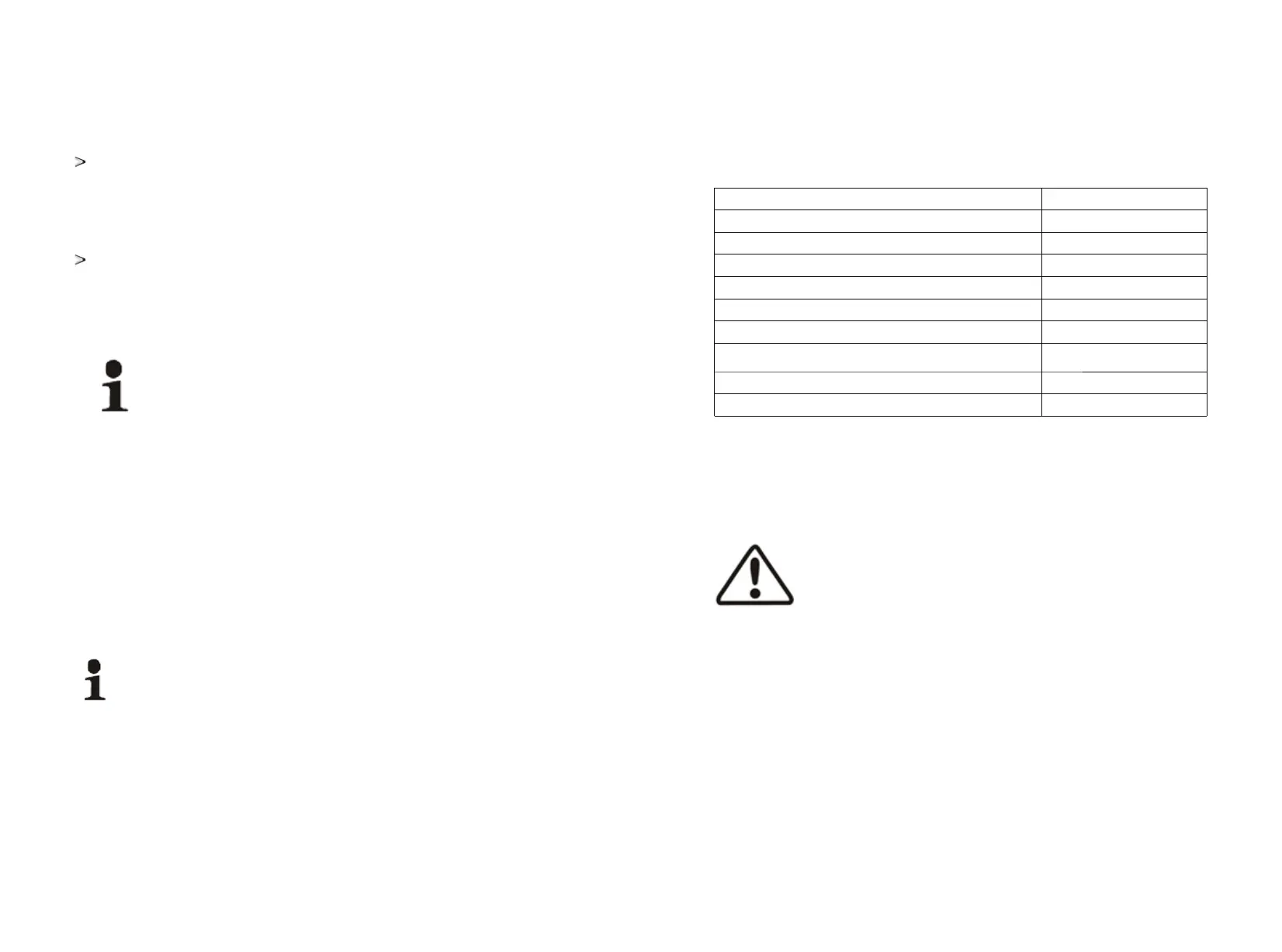

Maintenance item

Read data from data logger

clean heat sink of the power module

Check the dust, moisture or condensation inside the cabinet

Check the cable connections, and fix the screw if necessary

Check the warning label, add or replace some if necessary

Manual checks AC and DC circuit breakers

Check that the emergency stop button,

and the LCD stop function

Check if there is abnormal sound when inverter is operating

Check if the battery is abnormal, bulging or smoking

Cycle

every month

every month

every month

every month

every month

every month

every month

every week

every day

Figure7-2 Routine maintenance work

9

.

1.

3

Reg

ul

ar mai

nte

n

a

nc

e

In order to ensure the normal operation of the PBD, regular maintenance work is required.

Recommended routine maintenance cycle and work, as shown in Table 7-2.

CAUTION!

All maintenance operations must be carried out in the condition that DC side of the PBD,

corresponding switch of battery and PV moduel are all disconnected. Maintenance must

be proceeded only after AC and DC disconnected for at least 5 minutes, in order to

avoid electric shock!

9.2 Waste disposal

PBD will not cause environmental pollution, since the all the components meet the requirements

of environmental protection. According to environmental protection requirements, user shall

dispose the inverter in accordance with the relevant laws and regulations.

39 40

Loading...

Loading...