General preparations

Step Action

1 Install the compressor, see the sections Dimension drawing, Installation proposal and

Main fuses and supply cables.

2 Stick labels near the control panel to warn the operator that:

•

the compressor may start automatically after a voltage failure

• the compressor is automatically started and stopped

• the compressor may be remotely controlled

3 A number of VCI (Volatile Corrosion Inhibitor) plates are provided inside the bodywork to

protect the compressor against corrosion. Remove the plates.

4 If the compressor has not run for the past 6 months, it is required to improve the

lubrication of the compressor element before starting. Fill up the compressor element as

described in section Oil change (paragraph: Filling the compressor element with oil).

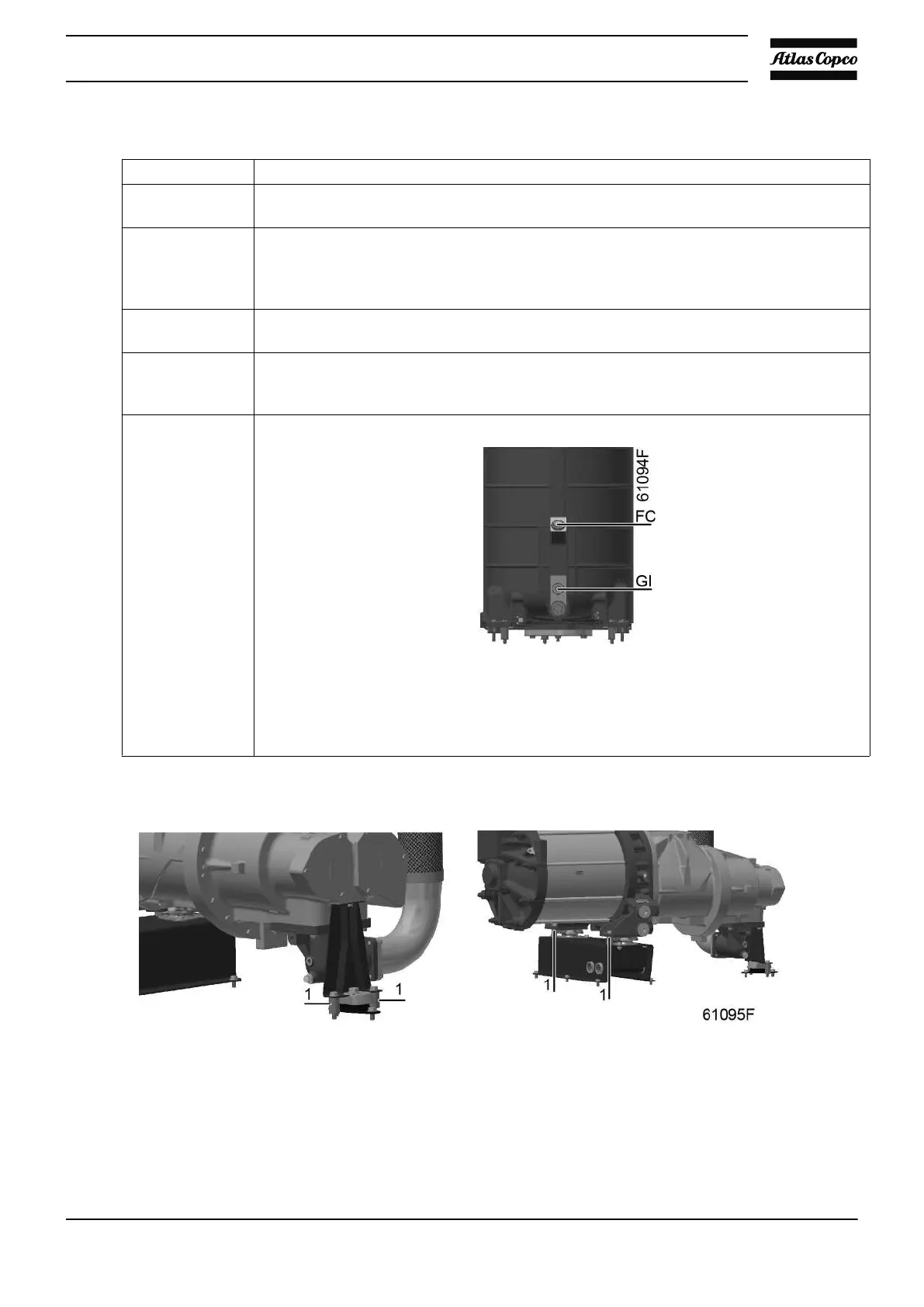

5 Check the oil level. The oil level should reach the bottom of the oil filler neck (FC).

The minimum level should reach the oil sight-glass (GI) when the compressor is

stopped.

If needed, top up the oil.

Take care that no dirt drops into the oil system.

Refit and tighten the filler plug (FC).

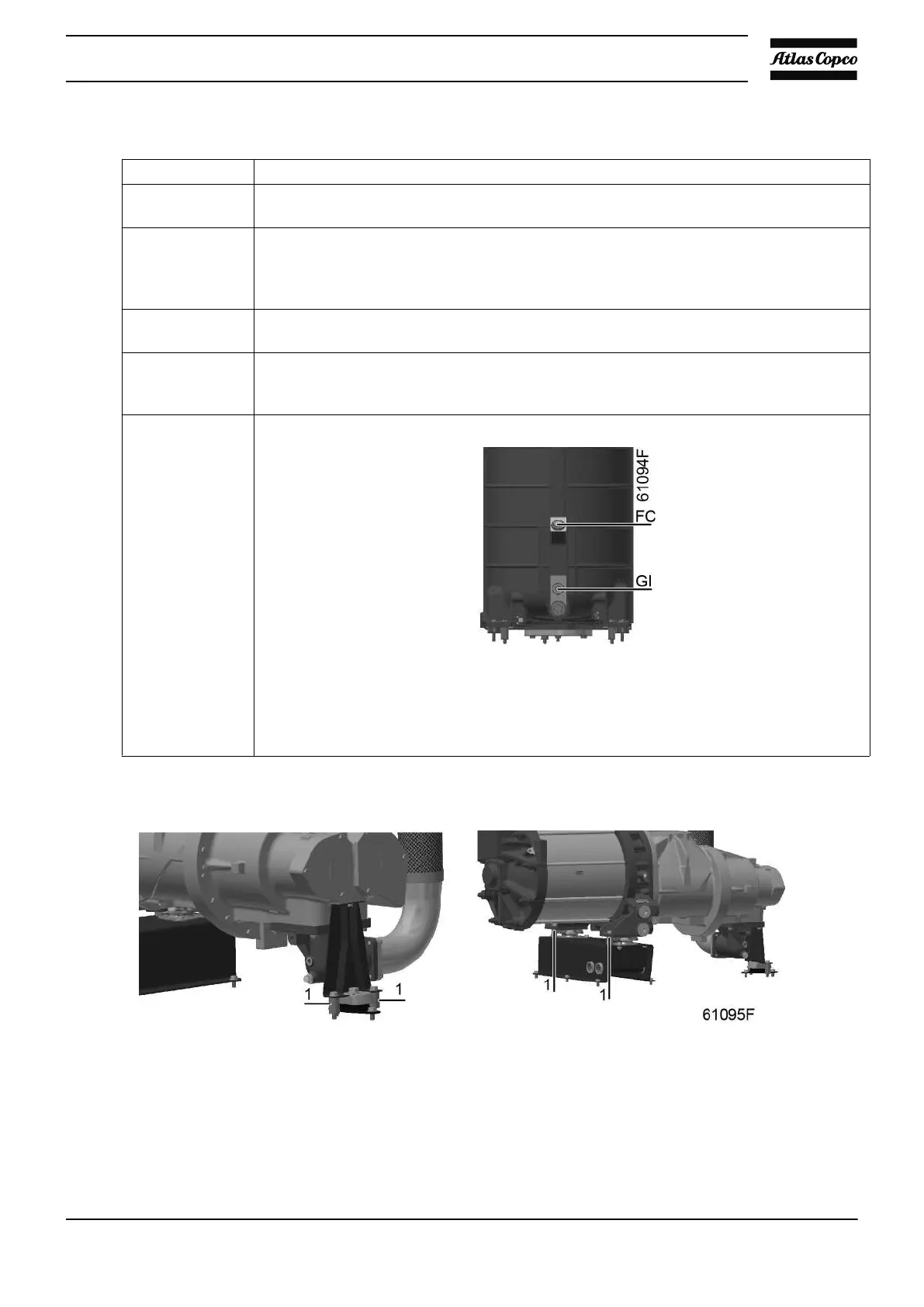

Protection during transport

Transport fixtures

Instruction book

9829 3178 63 77

Loading...

Loading...