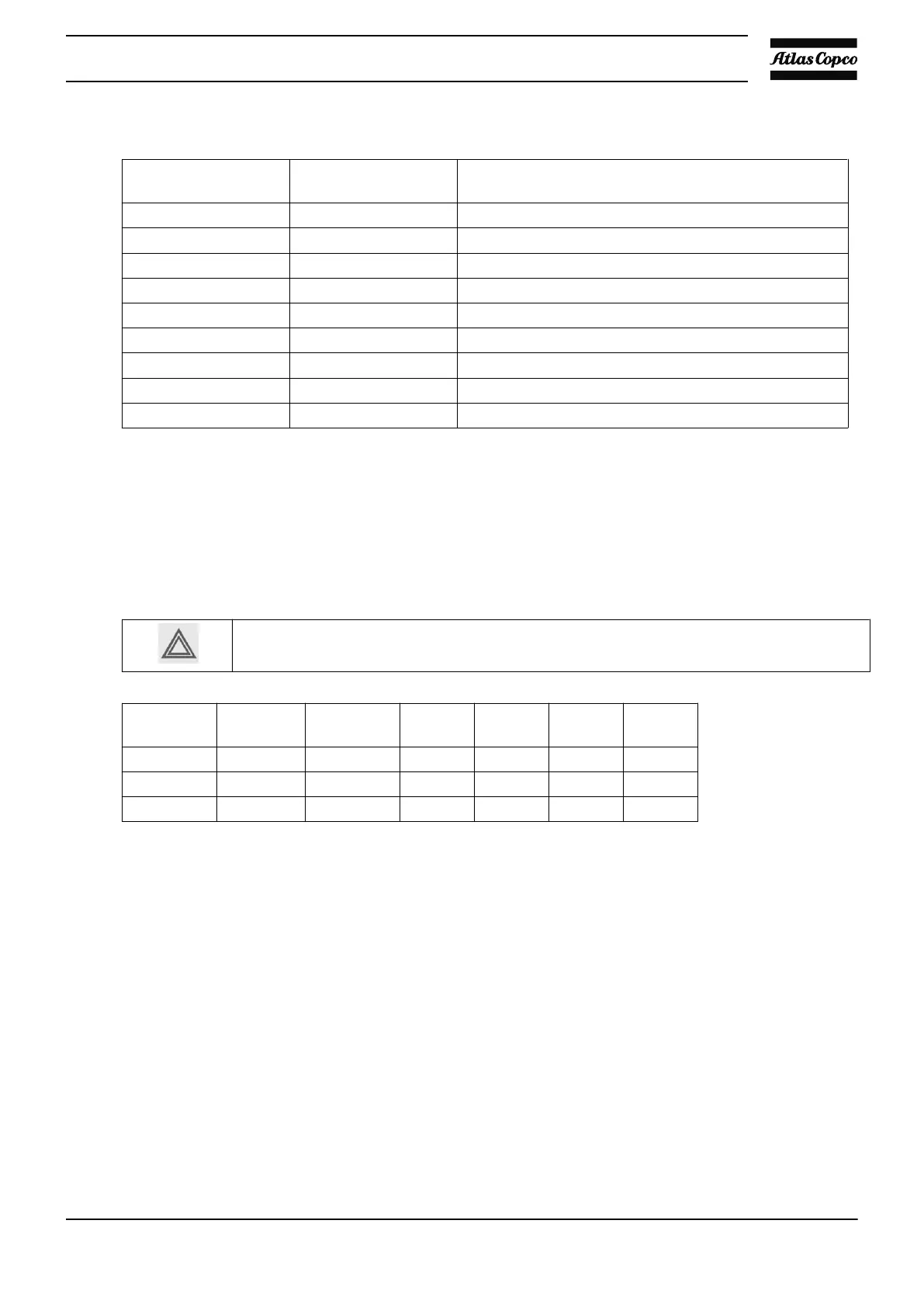

Temperature correction factors

Medium temperature

(°C)

Medium temperature

(°F)

Correction factor for maximum working pressure of

the compensator

0 32 1

50 122 1

80 176 1

85 185 0.92

90 194 0.83

95 203 0.75

100 212 0.67

105 221 0.6

110 230 0.54

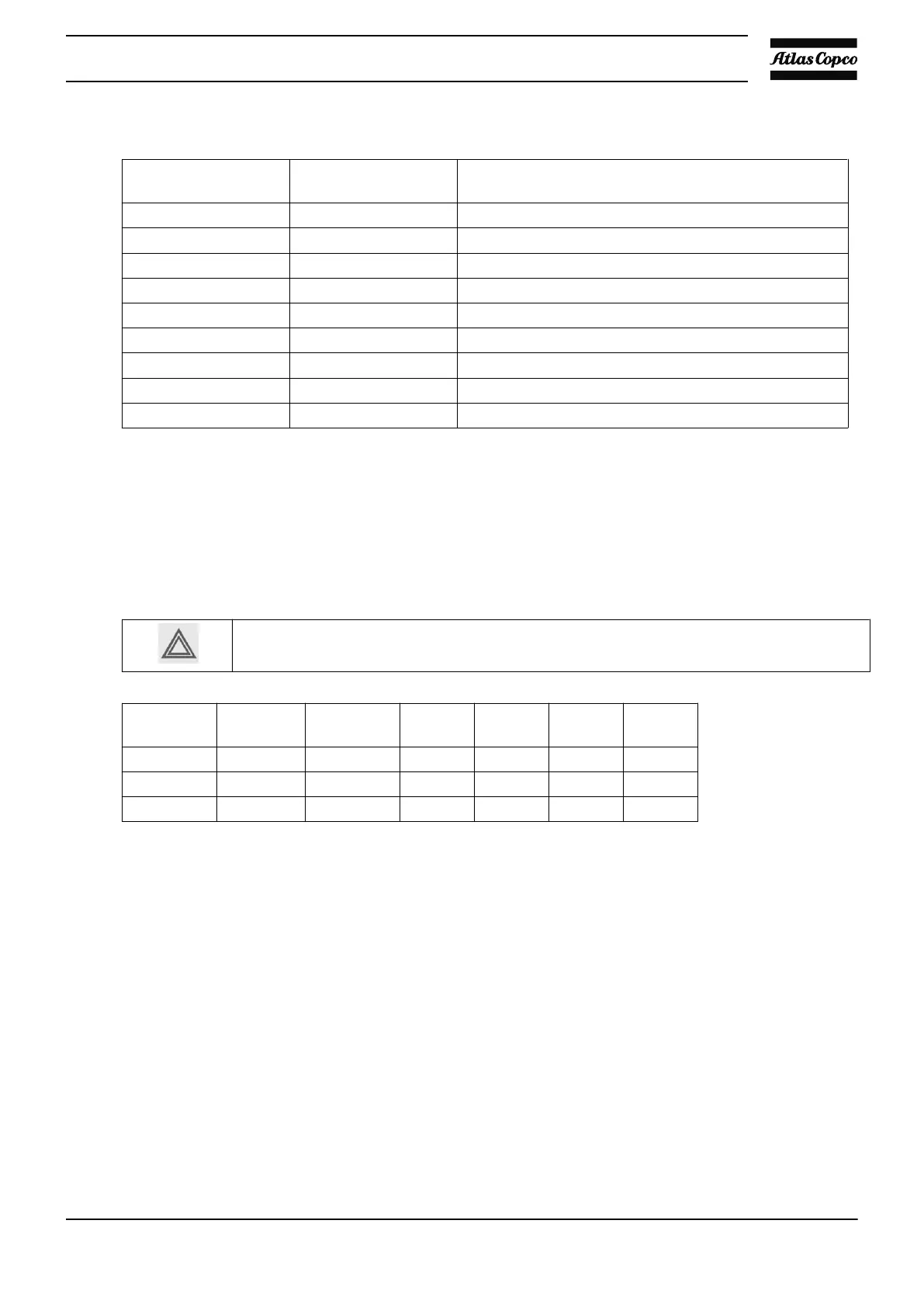

Torque values

Compensator bolts should be torqued in 3 successive steps

• Step 1: Hand-tighten each bolt.

• Step 2: Torque the bolts crosswise up to the value mentioned in the table below and allow a

stabilization period of 30 minutes before moving to step 3.

• Step 3: Torque the bolts crosswise up to the value mentioned in the table below.

• Mind the parallelism of the sealing.

• Excessive torque will damage the sealing.

DN

(mm)

DN

(inch)

Step 1 Step 2

(Nm)

Step 2

(lbfin)

Step 3

(Nm)

Step 3

(lbfin)

20 – 80 2 – 3 hand tight 50 443 80 708

100 – 300 4 – 12 hand tight 50 443 100 885

350 – 500 14 – 20 hand tight 50 443 130 1551

Do's and don'ts

The supplied compensators are NOT designed:

• to carry the weight of the mounted customer pipe end.

• to work as a damper for unanchored pipe ends.

• to carry the thrust forces of the compressed air.

Therefore, adequate supporting and anchoring of the customer pipe end should be foreseen to avoid

compensator damage.

Instruction book

2920 1815 04 209

Loading...

Loading...