9.4 Additional maintenance operations in environments with corrosive

agents

If the Radio Remote Control is used in environments where corrosive agents are present

(by way of example: sea water, salt fog, salt...), apply grease to the electrical connections

to protect them.

Only use electrically non-conductive, polyalphaolen and silicate-based

grease for electrical contacts.

Do not use polyether-, polyoilester- and polyphenyl ether-based grease.

Macon Research's Electric Grease CN 4070 can be used.

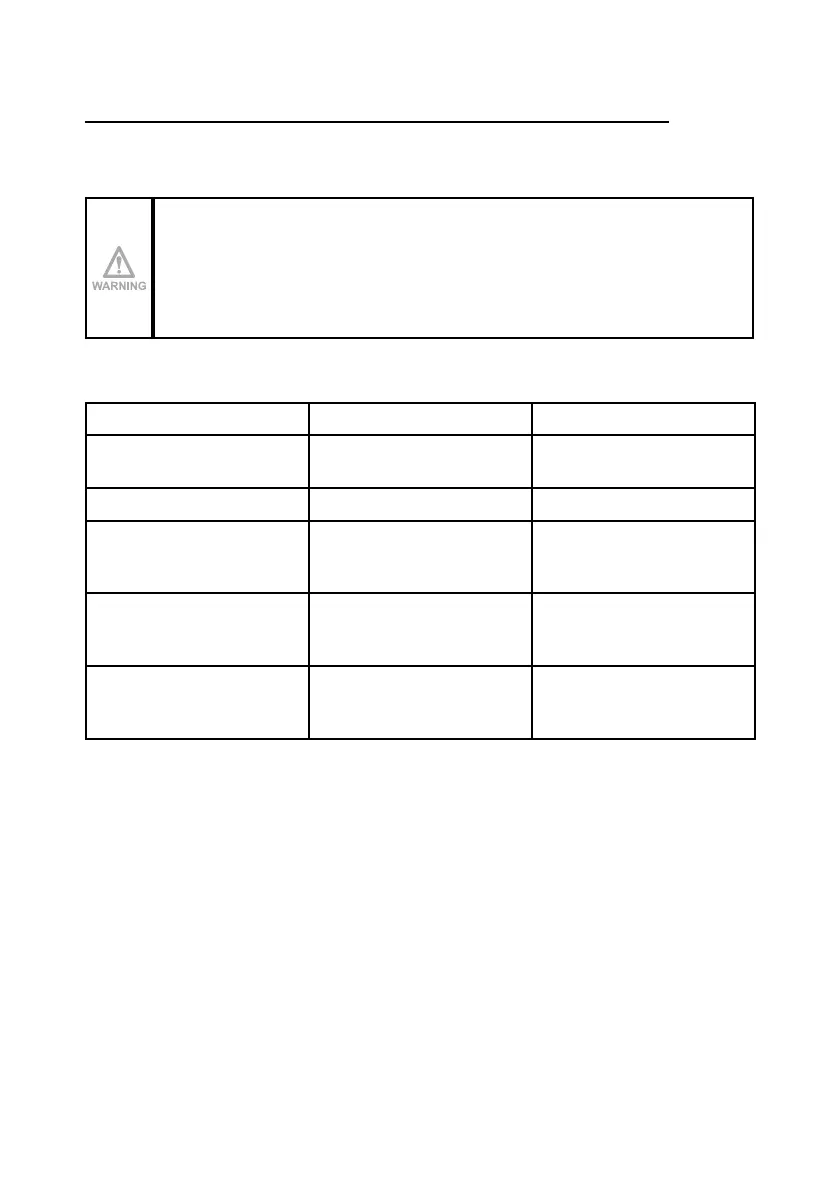

Check and replace grease as frequently as shown in the following table:

Type of connection Grease check frequency Re-greasing frequency

Connector for external

antenna

every 4-6 months If dirt and impurities are found

Receiving Unit's plug every 4-6 months If dirt and impurities are found

Connectors for Transmitting

Unit's and Receiving Unit's

cable control

h

1 month

If dirt and impurities are found,

and once a year anyway

Contacts of Transmitting Unit,

Battery Charger and battery

weekly

If dirt and impurities are found,

and once every three months

anyway

Key ID 0-1 weekly

If dirt and impurities are found,

and once every three months

anyway

h. It is recommended to disconnect the cable control cable and to store it in a protected place when

it is not in use.

When carrying out this kind of maintenance operations, follow these recommendations:

- make sure that the surface of electrical connections is covered with a layer of grease

and add it if necessary,

- contact the support service of the Machine's Manufacturer if evident oxidation is detected.

46

LIUDTH000_eng-01

Maintenance

AUTEC - Dynamic+ series

Loading...

Loading...