39

empty filter cartridge (this will ensure the

filter is not affected by the disinfectant/

sterilant solution).

3. Fill the water system with a disinfectant/

sterilant solution (check that the solution at

full strength appears at all taps/showers).

Allow to stand for the recommended

period of time.

4. Drain the system completely.

5. Thoroughly clean the outside of all taps/

connectors with a cloth soaked in the

disinfectant/sterilant.

6. Flush the system through with clean

drinking water until no traces of

disinfectant/sterilant can be detected at

any tap.

Suitable sterilising chemicals are available

from your motorhome dealer, accessory

shop, chemist or home-brew shops. It is not,

however, recommended to use bleach or

sodium metabisulphite.

Waste water system

(i) The waste water holding tank is

secured underneath the chassis of your

motorhome and is gravity fed.

(ii) In order to eliminate unpleasant odours as

much as possible, only smooth bore pipes

are used.

However, should the waste water tank be

overfilled, then the waste water will backfill the

drain pipes until it eventually appears in the

shower base. In order to prevent this, please

take note of part (iii).

(iii) The waste water gauge shows the level of

the tank in half increments, it is therefore,

recommended that the waste water tank is

checked on a daily basis, emptying when

required. This is done by opening the valve

located just beneath the side skirt on the

exterior of the Motorhome.

(iv) The waste tank may be drained by the

drain tap (grey) situated below the floor sill

of the van.

It should be emptied either directly, or via a

waste water container (not supplied) into a

designated waste water area.

PRESSURE SWITCH

The purpose of a pressure switch is to monitor

the pressure on the outlet side of the pump.

When a tap is closed, and the pump continues

to run, there is an increase of pressure in the

system, and when that pressure reaches a

pre-set limit, the pressure switch will turn the

pump off.

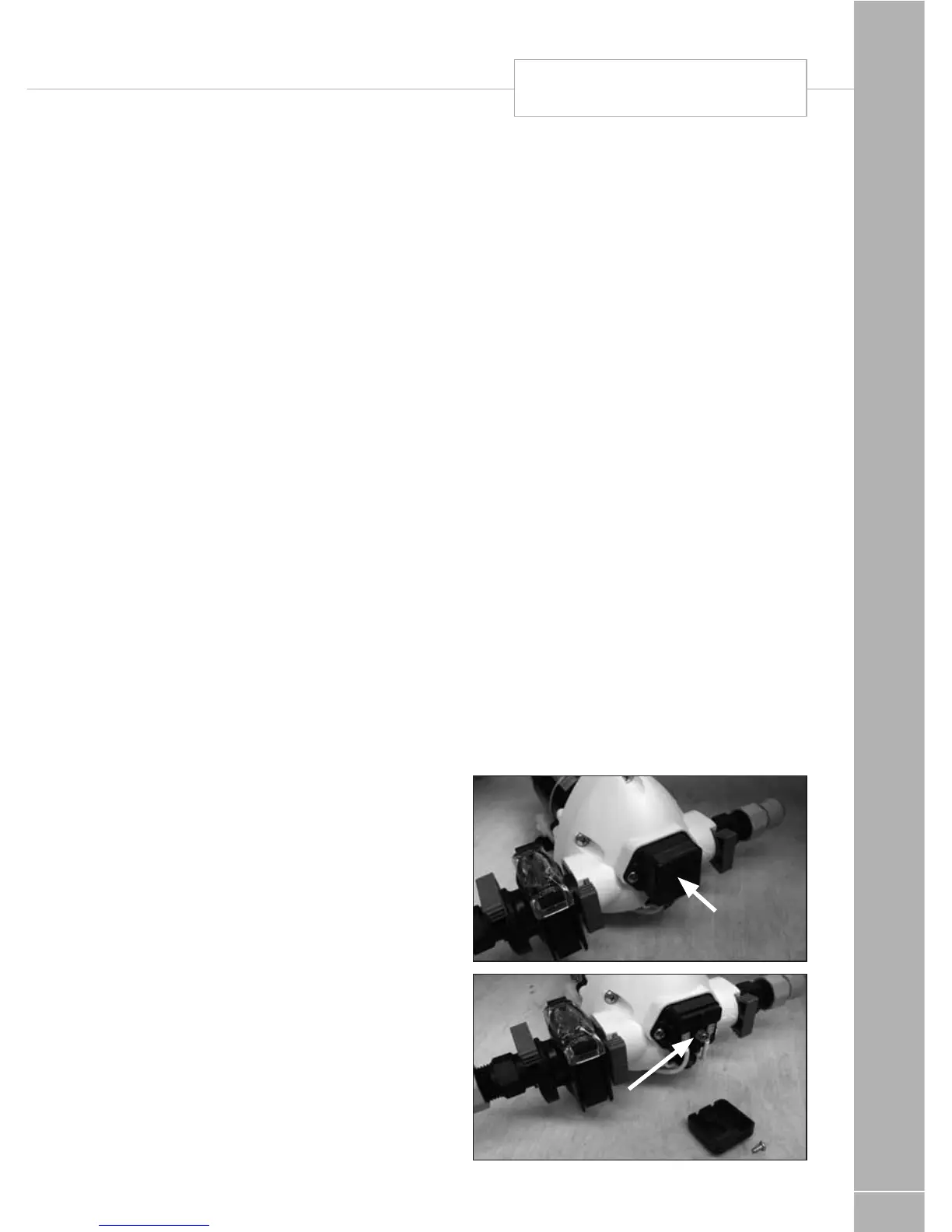

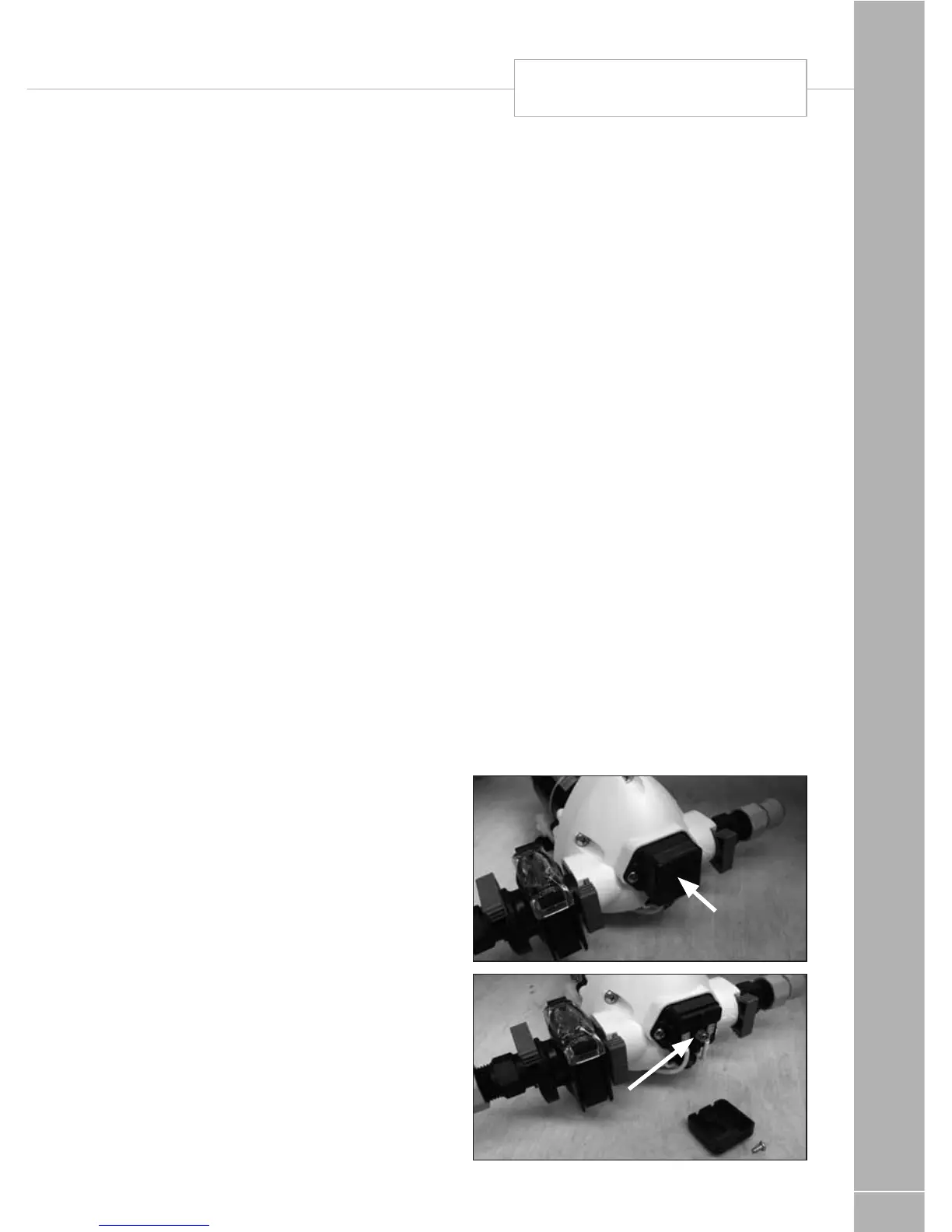

PRESSURE SWITCH ADJUSTMENT

Pressure Switch Adjustment, Truma/Flo-Jet

pump. (Normally Grey upper section with

White lower section/valve housing)

• AlloftheTruma/Flo-Jetpumpsusedby

Swift are pre-set at 25psi + / -3psi.

• Tofurtheradjustthepressureswitch

setting, a cover cap must be first be

removed from the end of the pump to

reveal a pressure adjusting screw, as

shown in the photos. A maximum of 1/4

turn clockwise or anti-clockwise, from the

factory setting, is advised. Turning the

screw clockwise 1/4 turn will increase the

pressure switch cut-out pressure, turning

the screw anti-clockwise will reduce the

pressure setting.

• Pleasenoteasecondscrewmounted

below the cover cap is set in position with

threadlock, this should not be disturbed.

Cover cap

Pressure switch

adjusting screw

pressure switch

Loading...

Loading...