Maintenance

14

AVL 415SE Smoke Meter — Maintenance Guide

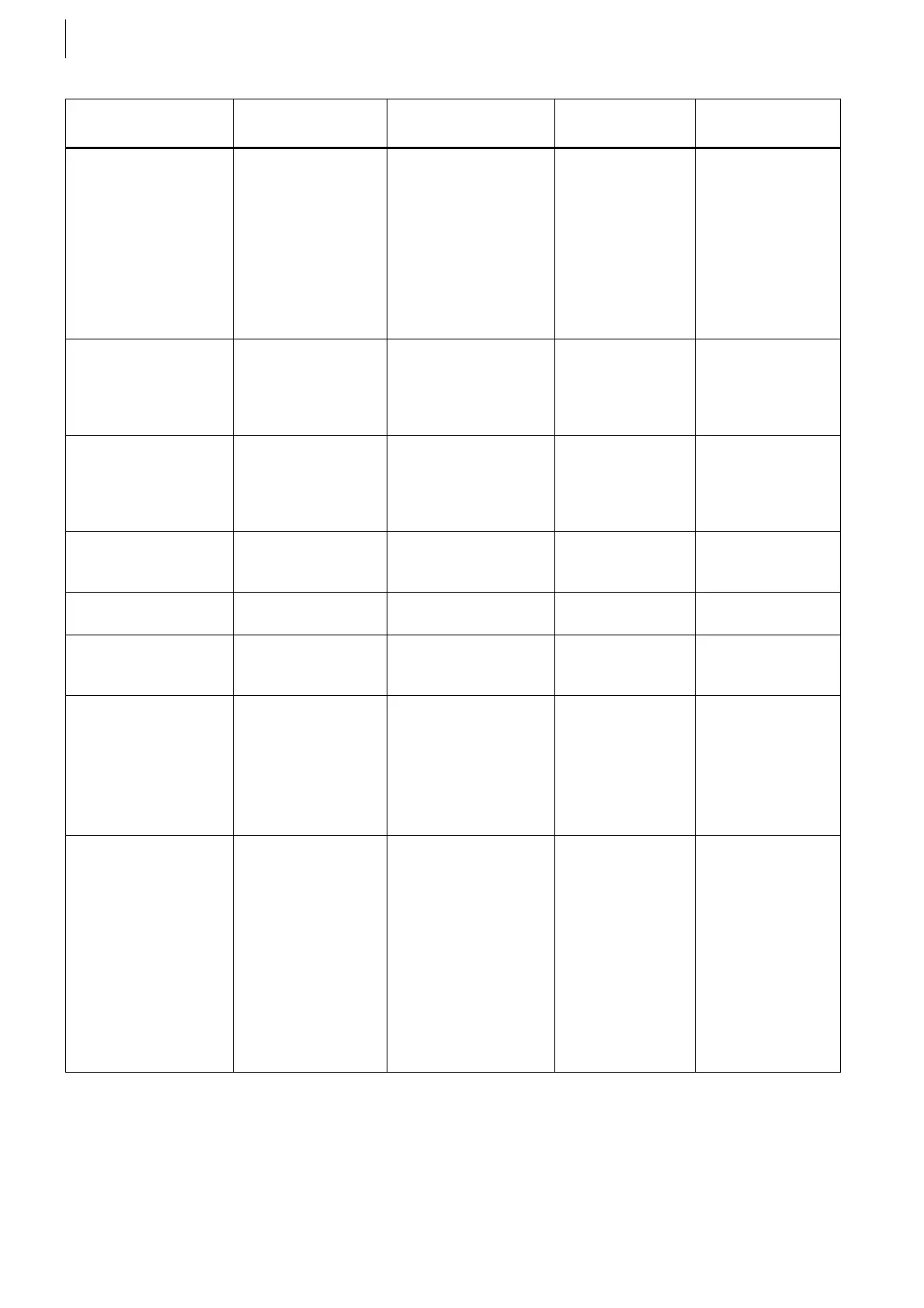

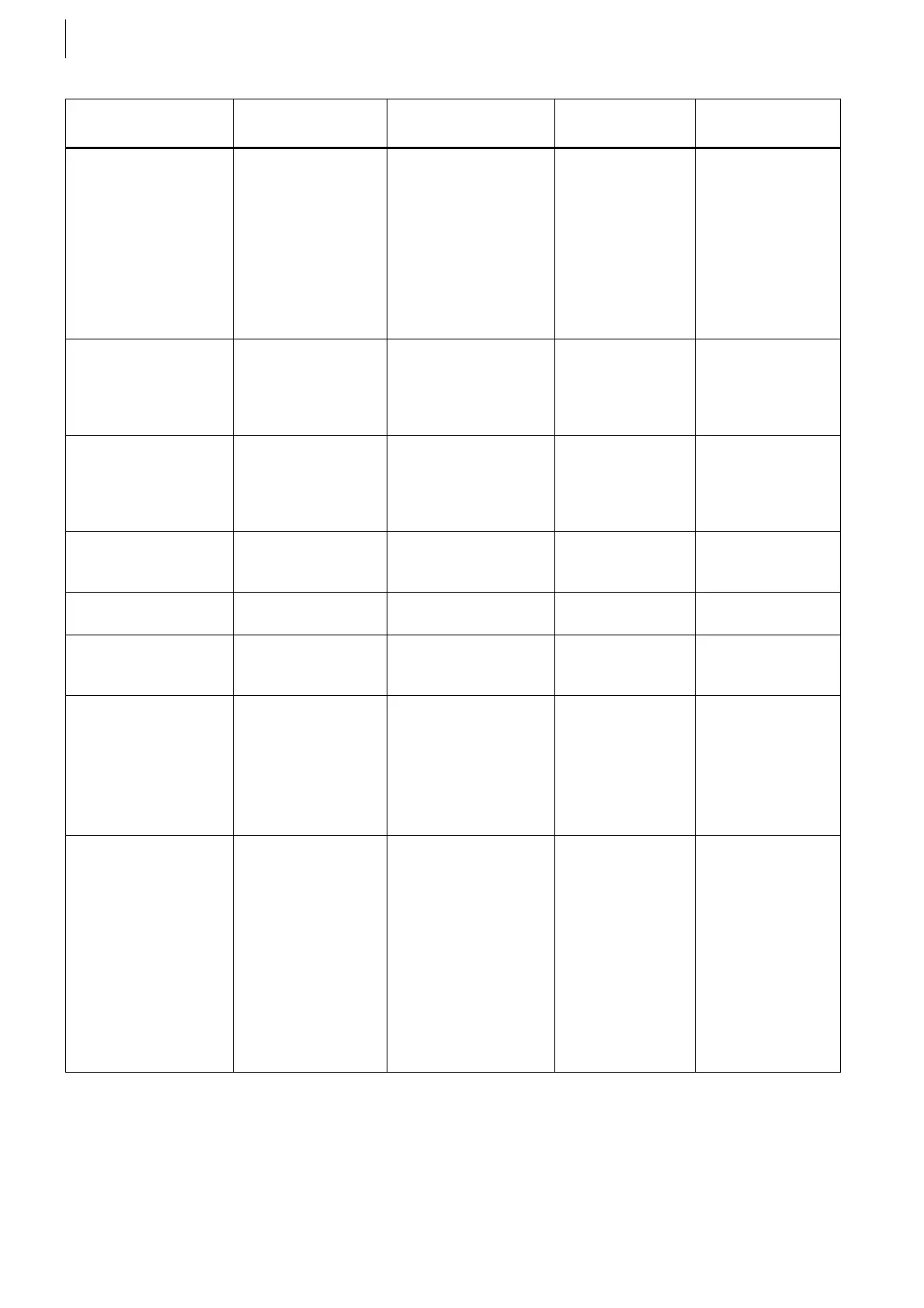

Component / Test Lifetime /

Service interval

Maintenance Replacement Procedure

Leak check Minimum every day.

After every filter

paper change.

After every manipu-

lation of the paper

transport.

Before & after every

volume tester cali-

bration.

For checks of sample

lines and probes:

supported on

SERVICE MODE only

perform with sampling

probe & line

– Section Leak

Check on page 41

Reflectometer head Every time the filter

paper is exchanged.

Check and clean if

necessary with a

puffer or a soft brush

or with compressed

air.

Every 2 years Section Reflecto-

meter Head on

page 27

Light gate 1 Every time the filter

paper is exchanged.

Check and clean if

necessary with

compressed air.

If damaged –

Replacement is

done by an AVL

Service Engi-

neer.

Camshaft Every time the filter

paper is exchanged.

Check and clean if

necessary with

compressed air.

Every 2-3 years or

after 3 000 oper-

ating hours.

Section Camshaft

on page 30

Fine filters Every time the filter

paper is exchanged.

Check. Following the

usage conditions.

Section Fine Filters

on page 31

White value plate Every time the filter

paper is exchanged.

Clean the deposit on

the standard with a

soft, wet cloth.

– Section Clamping

Lever and Ratchet

Clip on page 28

Filter paper Every time the filter

paper is exchanged.

Check the homoge-

neous blackening with

exactly delineated

round contour.

Check the backside of

the filter paper fpr

back flushed particles.

– Section Blackened

Filter Area on

page 22

Sealing ring of the

suction unit

Minimum every 5

times of filter paper

exchanged.

Check if there is no

deposit, clean if

necessary with a soft

or a damp cloth.

Glue the sealing rings

into the clamping

device (suction unit)

with Adhesive

3M-B20.

Check the sealing ring

for defects and correct

sea

ling ring position.

Replacement of

the sealing rings if

damaged; in this

case also order

mounting ring

30 mm.

Section Suction

Unit on page 24

Tab. 2

Loading...

Loading...