E2

MOUNTING

Location

Install the controller in a location that meets the following criteria:

•

Common mode voltages of I/O except power supply and relay con-

tact output: The voltage to ground is 30Vr.m.s. max., 42.4V peak

max., and 60V DC max.

•

Neither high nor low temperature/humidity.

•

Free from silicone gas and other corrosive gases such as sulfide gas.

•

Little dust or soot.

•

Protected from direct sunlight, wind or rain.

•

Little mechanical vibration and shock.

•

Not close to a high voltage line, welding machine or other source of

electrical noise.

•

At least 15 meters away from a high voltage ignition device for a boiler.

•

No strong magnetic field.

•

No flammable liquid or gas.

•

Indoors

Mounting Procedure

•

The mounting must be horizontal within 10 degrees tilted in back side

lowering or within 10 degrees tilted in back side rising.

•

The mounting panel should be used with a thickness of less than 9mm

of firm board.

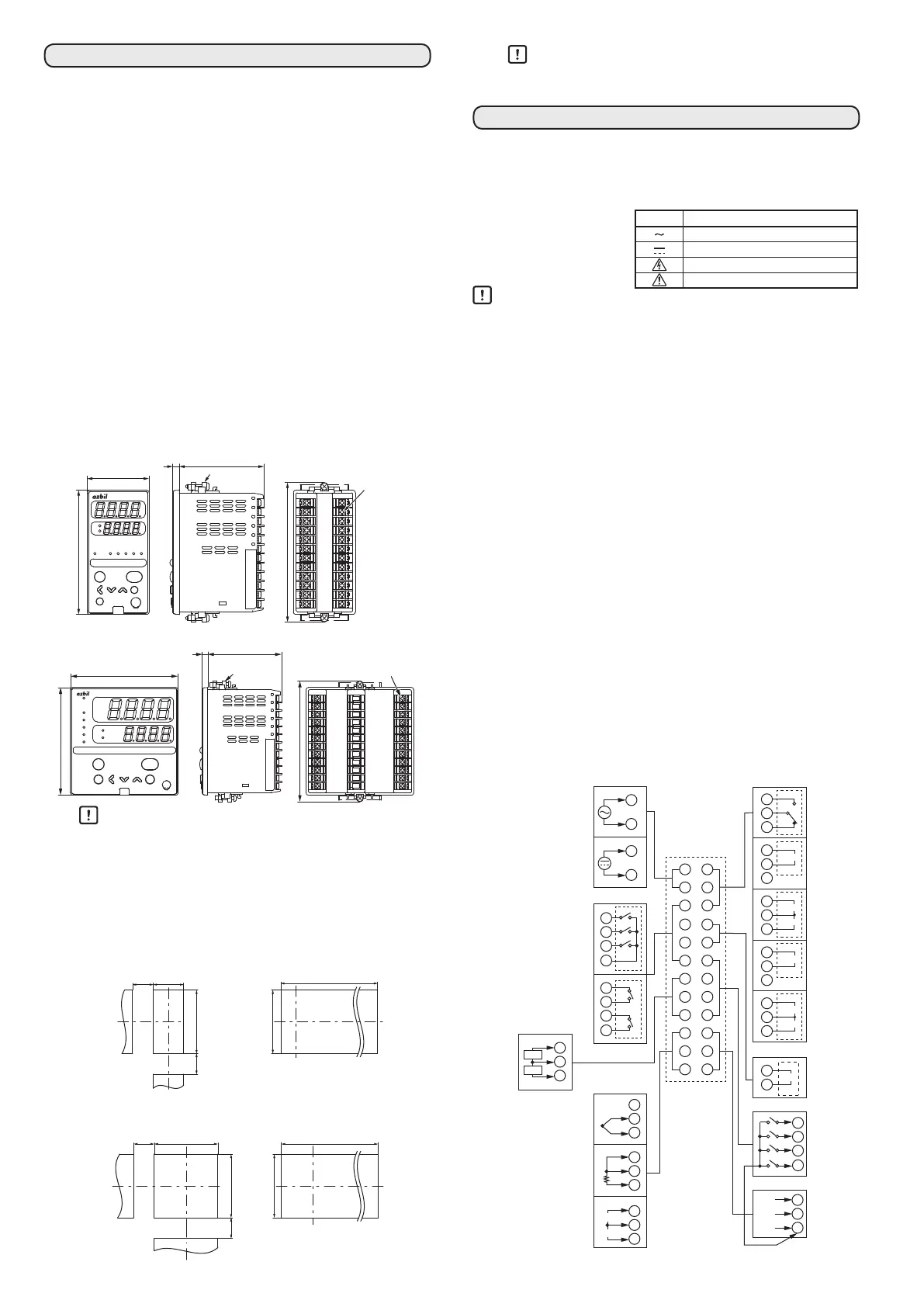

External Dimensions

z C25 unit: mm

para

enter

display

mode

pv

out

sp

108

48

ot2ot1ev3ev2ev1man

SDC25

Mounting bracket

(Accessory)

Terminal

z C26

mode

display

enter

para

man

ev1

ev2

ev3

ot1

ot2

sp

out

pv

Mounting bracket

(Accessory)

SDC26

108

96

Handling Precautions

•

To fasten this controller onto the panel, tighten a mounting

bracket screws, and turn one more half turn when there is no

play between the bracket and panel. Excessively tightening

the screws may deform the controller case.

•

Be sure to mount the unit in a panel so that operators do not

touch the rear terminal block.

Panel Cutout Dimensions

z C25 unit: mm

30

min.

92

44

30

min.

+0.5

0

+0.5

0

(48×N−4)

92

+0.5

0

+0.5

0

z C26

(96×N−4)

+0.5

0

92

+0.5

0

30

min.

92

30

min.

92

+0.5

0

+0.5

0

Handling Precautions

•

When three or more units are gang-mounted horizontally, the

maximum allowable ambient temperature is 40°C.

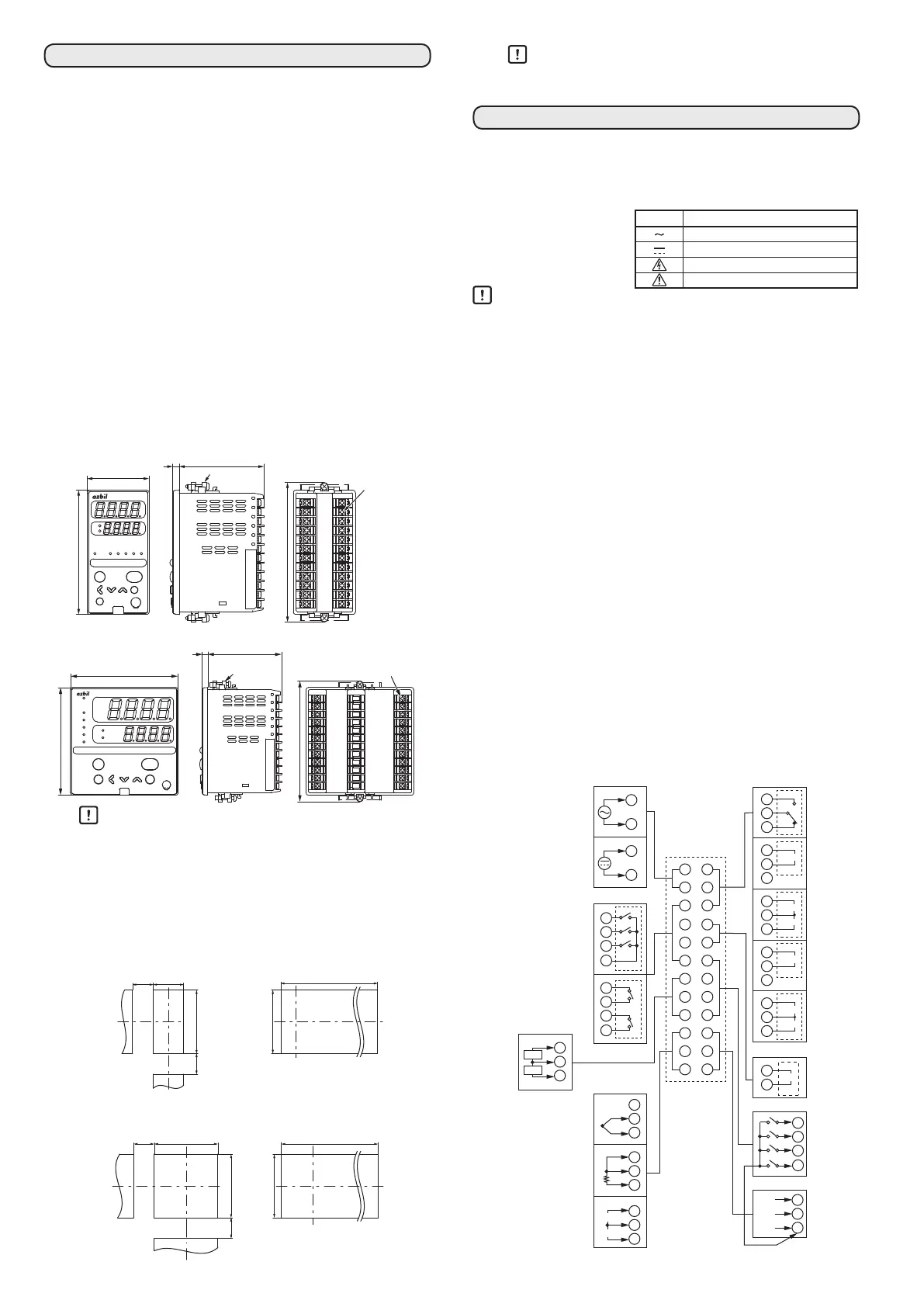

WIRING

All wiring should follow local regulations and be carried out by certified and

experienced personnel. Be sure to provide a switch within operator reach for

shutting OFF the main power supply to the controller in the main supply wir-

ing. Also, in case of AC power supply models, the main supply wiring also re-

quires a time-lagged type (T) fuse (rated current: 0.5A, rated voltage: 250V).

(IEC127) The following table

shows the meaning of the sym-

bols in the terminal wiring label

on the controller side:

Handling Precautions

•

Before wiring the SDC25/26, verify the controller’s model No. and

terminal Nos. written on the label on the side of the body. Inspect all

wiring once wiring work for the SCD25/26 has been completed.

•

Use M3 crimp-type terminal lugs for wiring to terminal.

•

Leave at least 50 cm between I/O signal wires and power wires. Do

not put them in the same electrical conduit or duct.

•

Be careful not to allow any crimp-type terminal lugs to touch adja-

cent terminals.

•

To connect 2 (max.) crimp terminals to the same terminal screw,

bend the crimp terminals beforehand.

•

When the power to this controller is turned off, the current input

circuit is cut off. If multiple current-input type SDCs are connected in

series and you want to turn them on/off individually, convert them

to voltage input by adding resistors (No. 81401325, sold separately)

to the circuit.

•

Prepare a heater current conductor to send a heater current through

the current transformer. Do not use a heater current that exceeds the

specified permissible current as this may damage the controller.

•

The current transformer input cannot be used for phase control.

•

There is no isolation provided between control output 1 and control

output 2. Install an isolator as required.

•

Do not connect a terminating resistor to either end of the RS-485

communications line. Doing so may interfere with communication.

•

Make sure that devices and equipment connected to this device

have reinforced insulation suitable for the maximum operating volt-

age of this device’s power supply and input/output ports.

•

The controller requires maximum 5 seconds to start up once the

power is turned ON. The controller can be used once it has started

up. However, it is recommended to allow a warm-up time of at least

30 minutes to attain the specified accuracy.

z Connection of C25/26

7

8

9

CT1

CT2

13

14

15

2

1

2

1

16

17

+

−

1

2

1

2

Digital input

RS-485

22

23

24

DA

DB

SG

18

19

20

21

3

4

5

6

3

4

5

6

2

1

2

3

1

COM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

10

11

12

10

11

12

10

11

12

+

−

+

+

−

mA

V

C

B

A

13

14

13

14

15

13

14

13

14

15

+

−

+

+

−

+

−

+

+

−

COM

3

2

1

4

Inputs

AC power supply

100 to 240 V AC

DC power supply

24 V AC/24 V DC

(non polar)

DI

Auxiliary output

Communication

Current

Relay

Event outputs

Relay

Relay

(independent

contact)

Current

inputs

DC current

DC voltage

PV inputs

Thermocouple

RTD

Voltage pulse

Voltage pulse

Voltage pulse

Current

Current

Current

Symbols Meaning

AC power supply

DC power supply

Caution, there is danger of electric shock

Caution

Loading...

Loading...