39

AL-KO COUPLING

OVERRUNNING DEVICE

The device housing is packed with grease on

assembly, but will require periodic maintenance

to ensure smooth operation of the braking

system.

• Re-grease the shaft bearings via the grease

nipples provided at 3,000 mile intervals, and

before storage.

• Ensure correct functioning of all pivot pins

and levers, and oil regularly.

• Ensure correct functioning of handbrake

ratchet and oil regularly.

JOCKEY WHEEL

Lubricate wheel and screw thread periodically

with grease.

BRAKE LINKAGE

All moving parts should be lubricated

periodically to ensure their satisfactory

operation.

CORNER STEADIES

The screw and pivot pins should be lubricated

periodically to ensure their satisfactory

operation.

BRAKING SYSTEM ADJUSTMENT

(At 500 miles, then every 3,000 miles or 1

year)

1. Ensure the towing shaft with coupling heads

is pulled fully forward.

2. Release the handbrake to the fully off

position. If the handbrake will not go down the

whole way because of the fairing or any other

obstruction then the fairing must be cut away

and/or the obstruction removed to achieve

this desired position. It will not be possible

to set up the braking system properly when

the handbrake is not in the fully off position

(fig. 8).

3. Jack up one side of the caravan (see Jack

Operation Instructions).

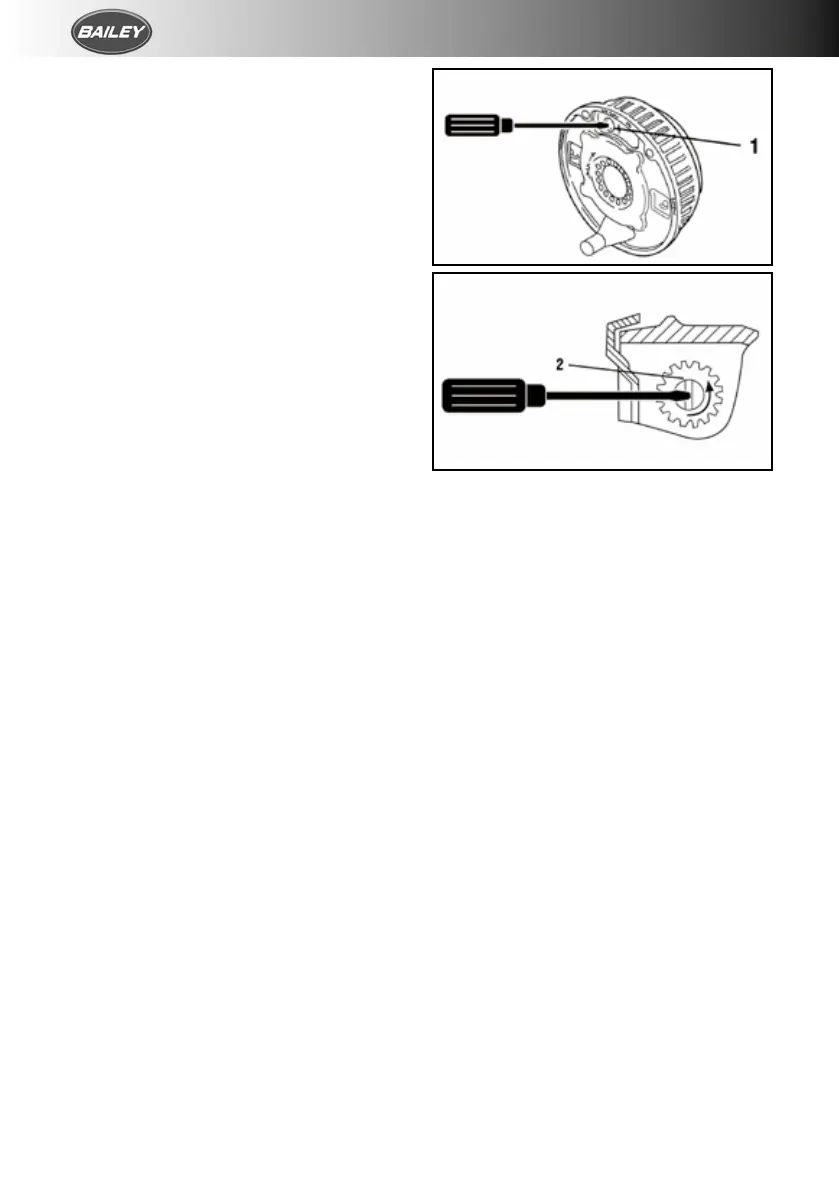

4. Remove the inner plastic bung from the

backplate to expose the “star-wheel” adjuster

access (fig. 8).

FIG 8.

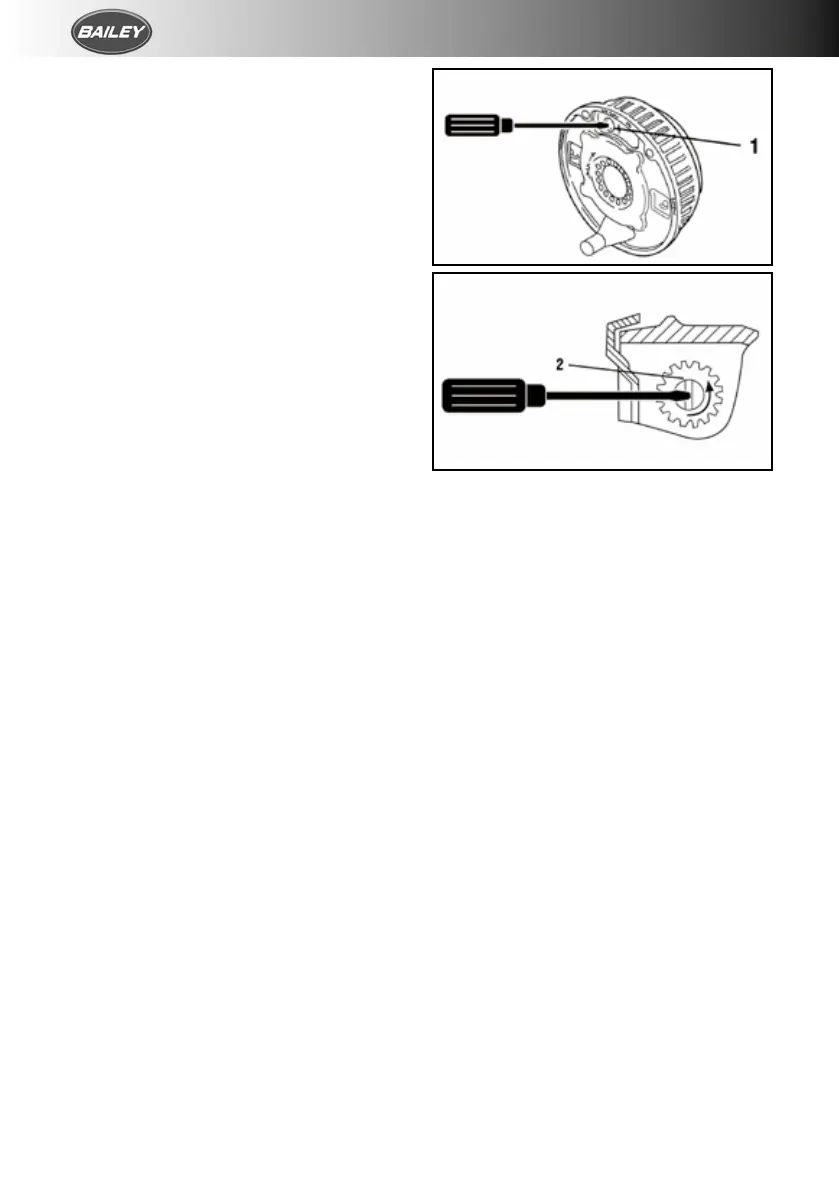

5. Rotating the road wheel in the forward

direction (never backwards), adjust the

star-wheel with a suitable screwdriver in

the direction of the arrow embossed on the

backplate until there is resistance in the wheel

rotation (fig. 8).

6. Slacken off the star-wheel adjuster until the

road wheel turns freely in the forward direction

(fig. 8).

7. Check the adjustment at the end of the brake

cable where it is secured to the abutment

(bracket) welded to the centre of the axle.

When the inner cable is pulled out it should

extend between 5 and 8 mm. (On tandem axles

a double abutment is fitted to the front axle

only).

8. Repeat for other wheel or wheels.

Loading...

Loading...