71

HEATING SYSTEMS

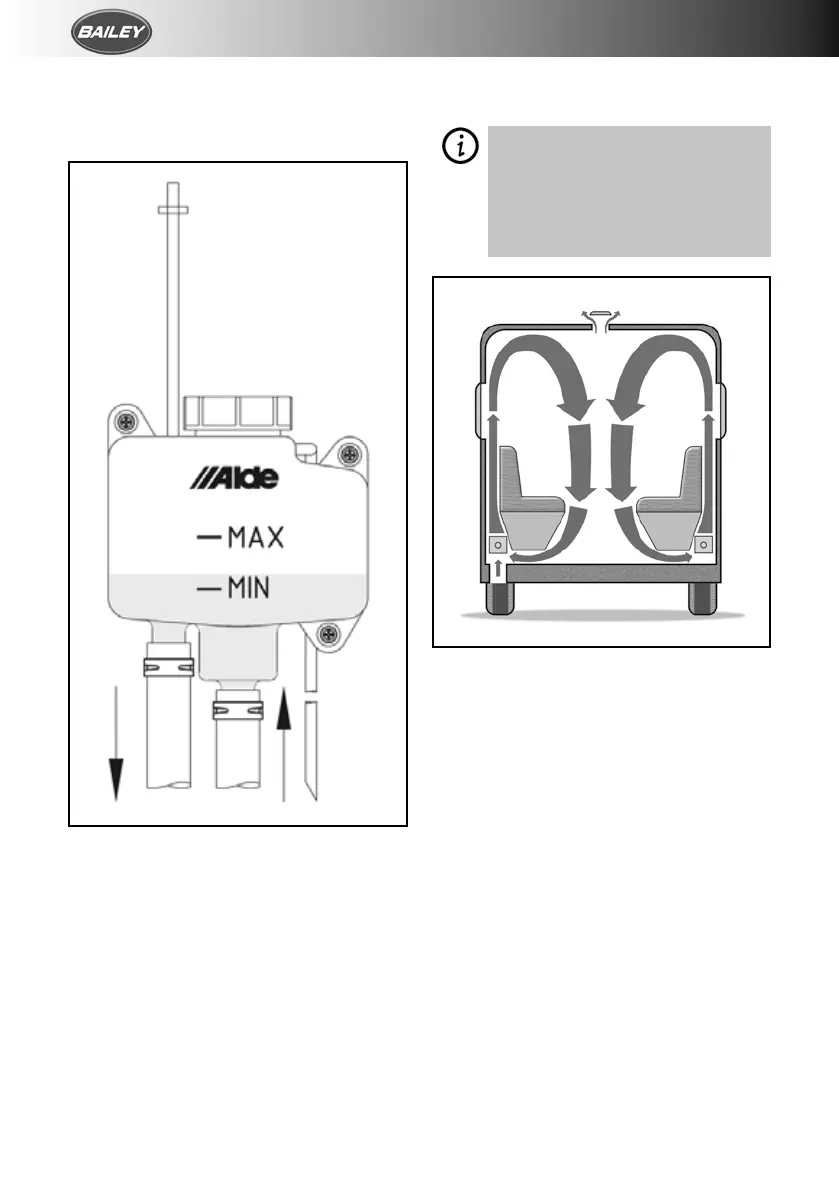

expansion tank cap (Fig.2 [R]) and remove

cap. Carefully pour the HTF into the tank, and

repeat until the fluid level is about 1 cm above

the MIN mark when cold.

Fig. 2

CENTRAL HEATING

The boiler is set to an upper limit temperature

of 85°C, i.e. the temperature of the heat

transfer fluid (HTF) as it circulates around the

pipes, radiators, convector, etc.

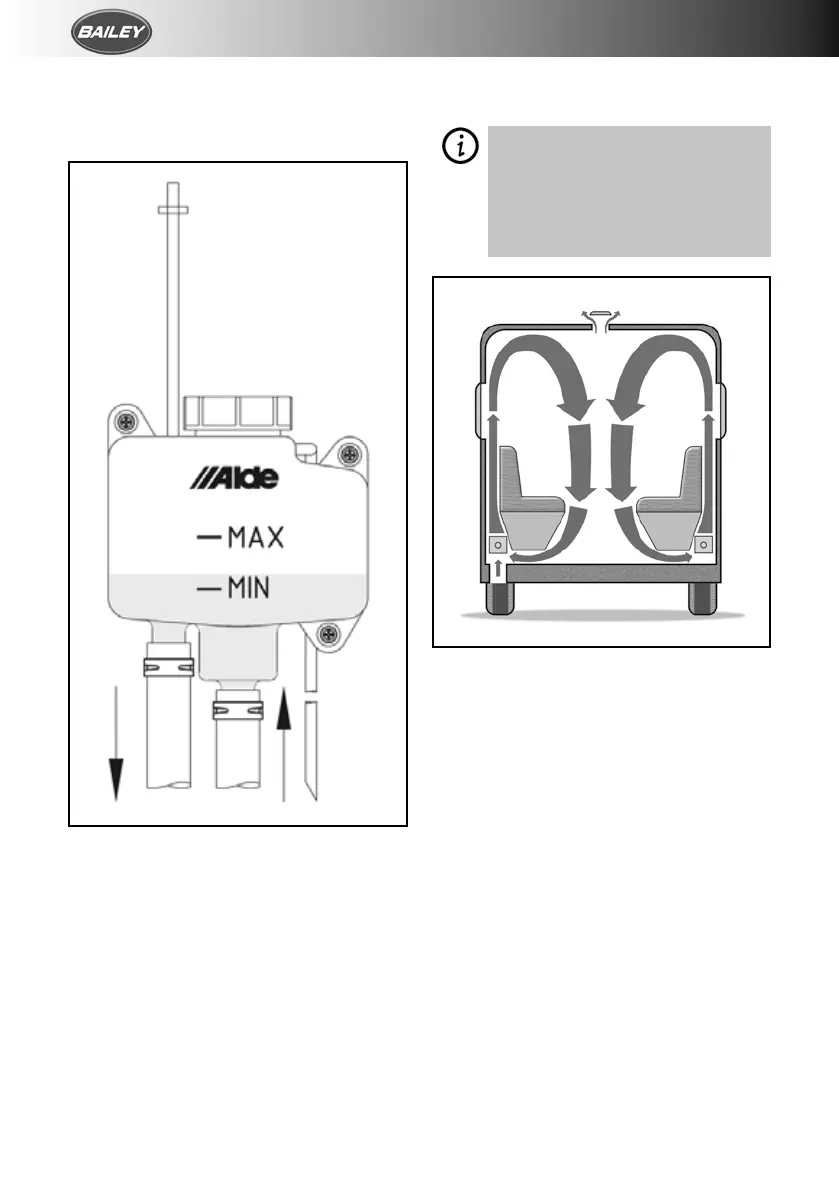

To ensure the best performance from hydronic

heating, air must be able to circulate freely

around the back of the furniture (Fig.3). Air

vents, cut into the top and bottom of the

furniture must be unobstructed by carpets,

cushions, or stowage, etc.

The full length of a convector should be

ventilated for best performance.

Use gas and electric heating

simultaneously for the best

performance. The boiler will only use

as much energy as is needed, and is

93% efficient on a SEDBUK (seasonal

efficiency of domestic boilers in the

UK) based test.

Fig. 3

CIRCULATION PUMP

A pump is used to circulate the HTF around the

central heating system.

BLEEDING AIR

The HTF will contain some air. This is

unavoidable. Air bubbles can also be

introduced when the system is filled.

In a newly filled central heating system you

will need to bleed air from the bleed points

to ensure best performance. There is an

automatic air bleed valve on the boiler. There is

also an air vent on the expansion tank.

The installer should fit bleed points elsewhere

in the system, especially where the pipes step

up and down, and on radiators and towel rails.

Air will accumulate at these high points and

become trapped.

Loading...

Loading...