201/21

MODEL 75 OPERATION

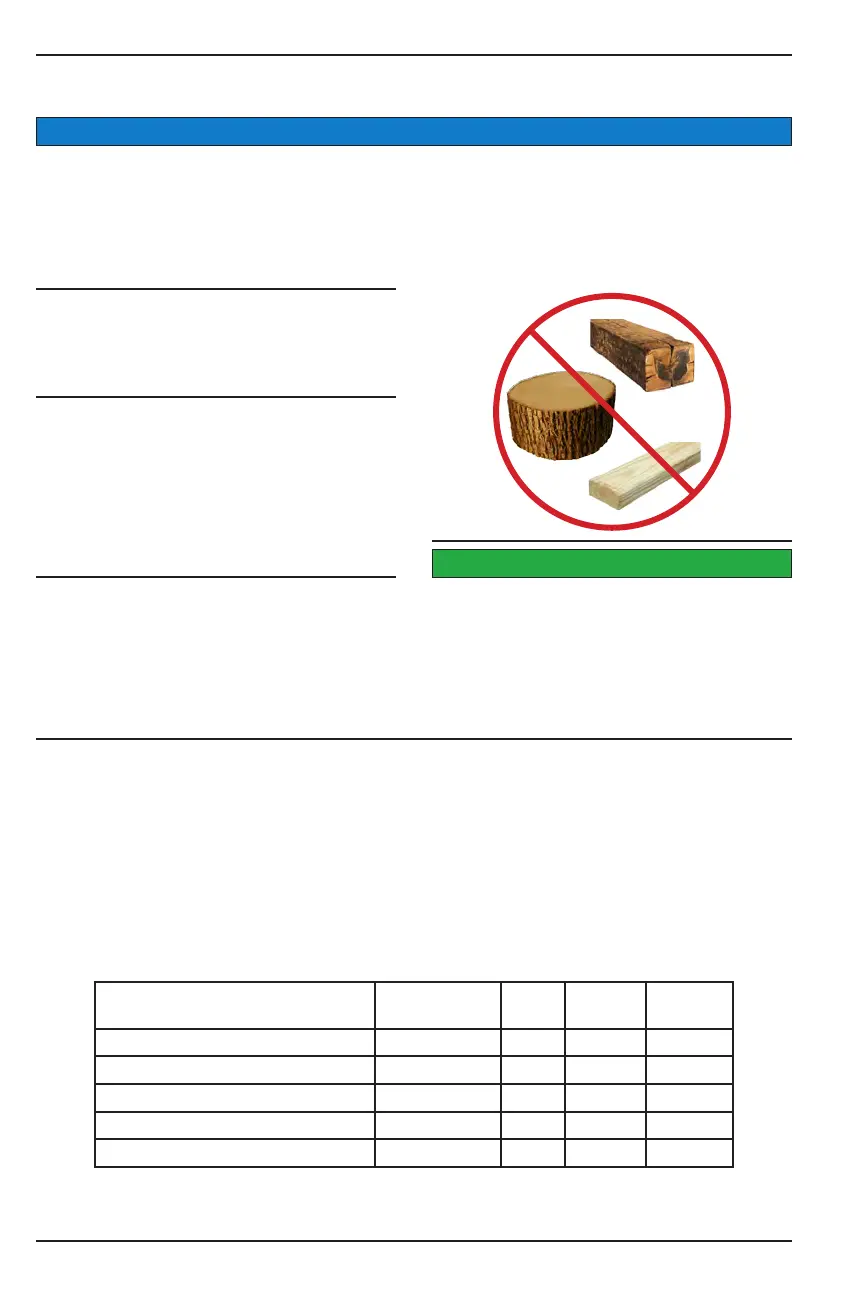

Some Current Engine Types Maximum RPM PPR O RPM On RPM

Kohler CH740 - 25 Hp 3400 99 3300 3050

Kohler CH980 - 35Hp 3600 99 3500 3250

Kohler CH1000 - 37 Hp 3600 99 3500 3250

Vanguard - 27 Hp 3600 99 3500 3250

Vanguard - 35 Hp 3600 99 3500 3250

Stop feeding material.

Allow the machine to clear out any remaining

Make sure the top feedwheel is in the lowered

Throttle the machine down.

Disengage the clutch.

Wait for the disc to come to a complete stop.

Shut the engine o .

SHUT DOWN

8.

Remove the key, and make sure it stays in your

possession.

9. Allow the machine to cool down

10.

Remove all debris, wood chips, sawdust, leaves,

etc. from the machine.

11.

If transporting the machine, follow the transport

procedures.

MACHINE OPERATION

NOTICE

Chippers are not designed to cut chunk wood,

dimensional lumber including rail road ties, or end

cut logs standing on end. Chipper knives coming in

contact with a at surface puts an extreme shock

load on the chipper disc components and bearings.

This can cause damage to the machine that will not

be covered under warranty.

To feed vine-like material, stop the feed system,

cut the vines or vine-like material into 4 to 5 ft. (1.2

to 1.5 m) lengths, in a clear area, away from the

machine, place them on the infeed tray, start the

feed system, and use the wooden pusher paddle

to guide them towards the feedwheel(s). Always be

in position and prepared to activate the feed control

handle.

SAFETY INSTRUCTIONS

A wooden push paddle has been provided to

assist in feeding smaller material. It is the owner’s

and operator’s responsibility to use and keep a

wooden push paddle with the machine and to also

secure it when transporting the machine. Do not

use any body parts or any steel devices inside the

infeed hopper area.

When feeding larger diameter wood, listen for the

engine to possibly lug down. If it starts lugging down

stop the feedwheel(s) by pushing the feedwheel

control bar to o , and let the engine recover to full

speed. If the machine is equipped with Autofeed

and it is functioning properly, the feed system will

automatically stop to let the engine recover. This will

help stop the machine from plugging the discharge

chute.

If there are short pieces, leaves, or twigs, leave

them until feeding longer pieces. While the long

pieces are feeding, simply toss the short pieces on

top of them. The longer pieces will take them on into

the machine.

If there is larger diameter wood, try to feed it with

smaller diameter wood. Start a small diameter limb

which will partially open the feedwheel(s). Once the

feedwheel(s) are partially open it is much easier to

insert the larger diameter wood.

Loading...

Loading...