Bandit39

MODEL 75 MAINTENANCE

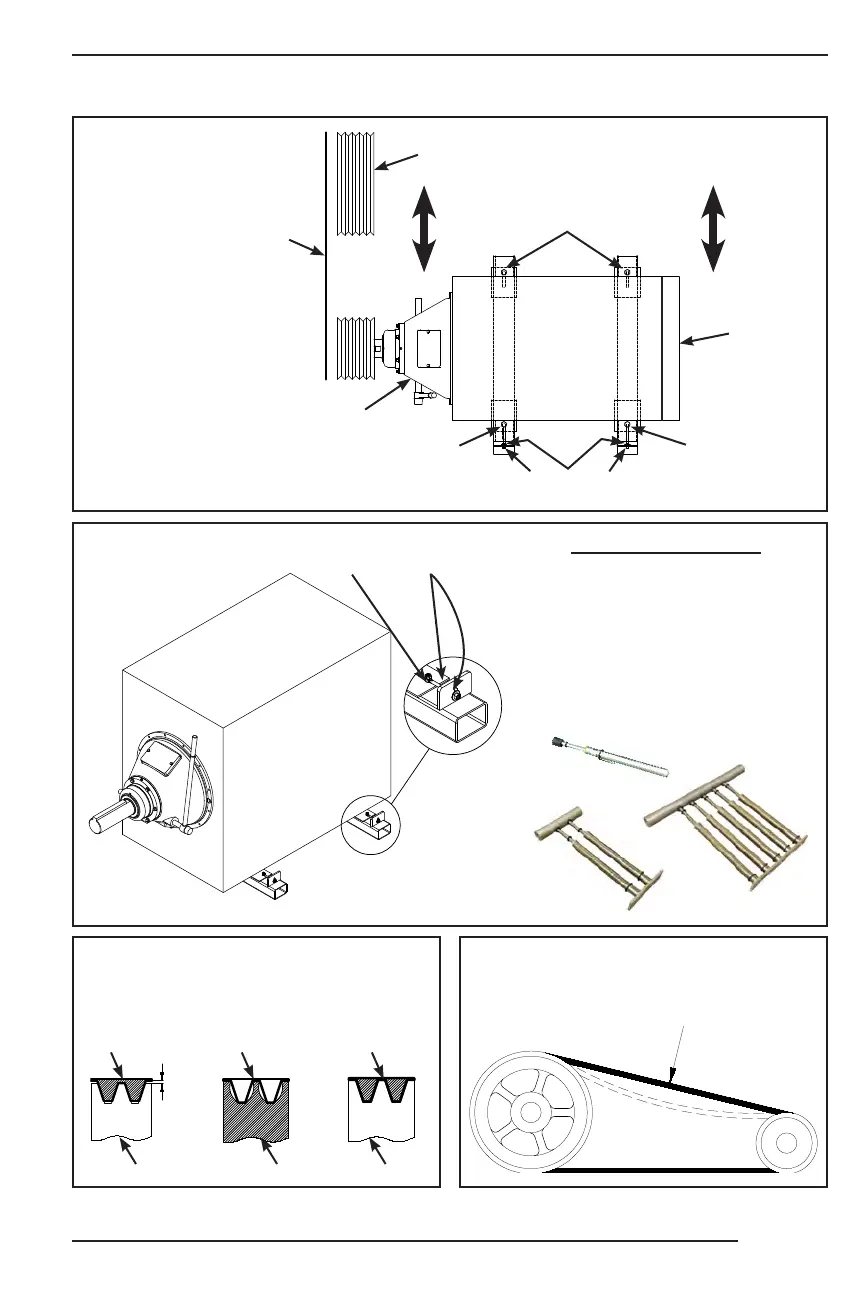

Main Drive Belts: Refer to “Belt Tension Table”

Pump Drive Belts: 1/4” (6.4 mm) deection with

9 lbs. (4.1 kg) of force.

BELT

SHEAVE

WORN BELT

BELT

SPACE

GOOD BELT

SHEAVE

BELT

SHEAVE

WORN SHEAVE

Worn or misaligned belts and sheaves in the power train

causes belt slippage, thus power loss. Keep the power

train working for you, not against you, by checking for

needed adjustment or replacement.

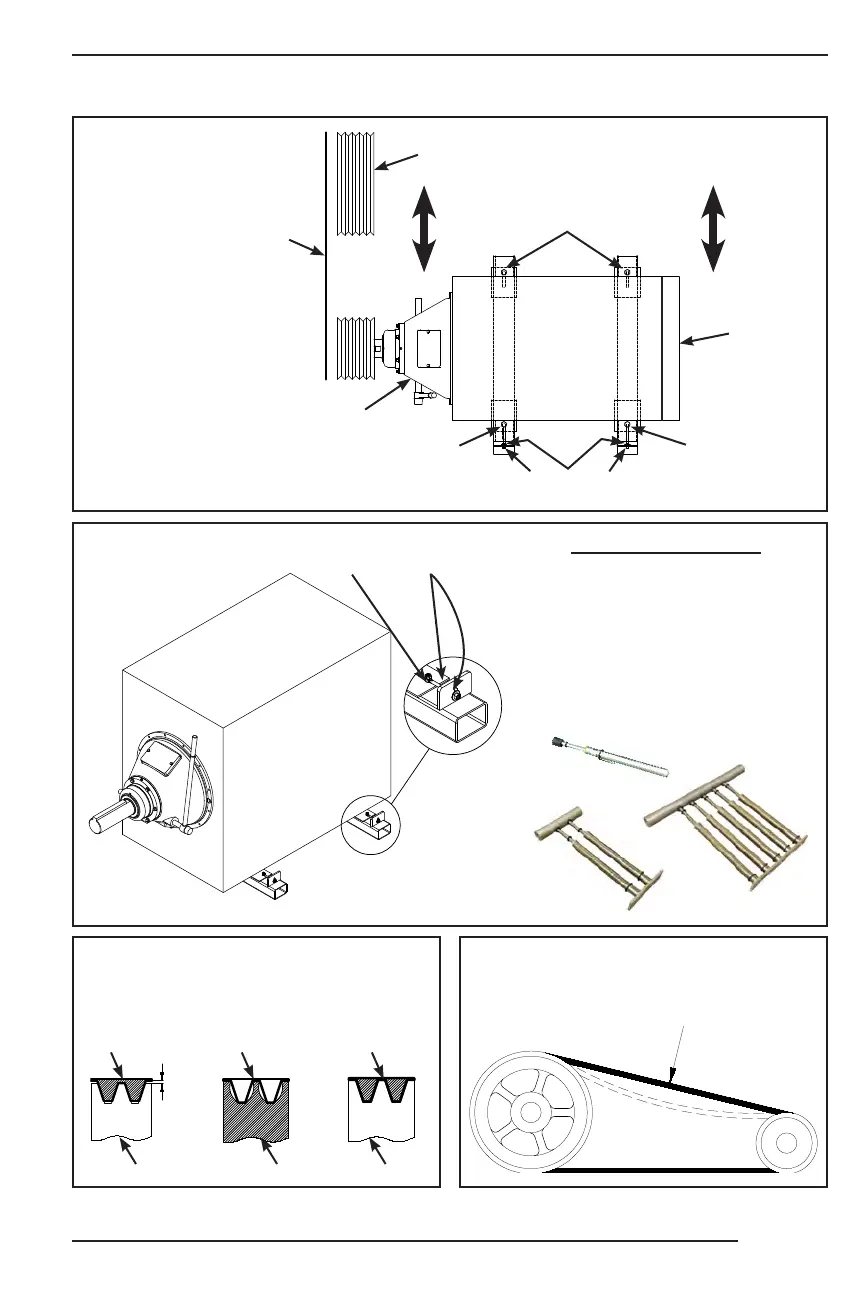

BELT TENSION

FIGURE 1

POSITIONING

JAM NUTS

CLUTCH END

OF ENGINE

CHIPPER

SHEAVE

ENGINE MOUNTING

BOLTS

ENGINE

SHEAVE

CHECK SHEAVE

ALIGNMENT WITH

STRAIGHT EDGE

OR STRING

RADIATOR

END OF

ENGINE

ENGINE

MOUNTING

BOLT

ENGINE

MOUNTING

BOLT

FIGURE 2

BELT TENSION GAUGES

SINGLE BARREL GAUGE

(UP TO 30 lbs.) 900-1919-23

DOUBLE BARREL GAUGE

(UP TO 66 lbs.) 900-1917-02

TRIPLE BARREL GAUGE

(UP TO 90 lbs.) 900-1919-67

FIVE BARREL GAUGE

(UP TO 165 lbs.) 900-1919-66

ENGINE

ADJUSTER

POSITIONING

JAM NUTS

Loading...

Loading...