Manual 2100-354

Page 24

SUCTION AND DISCHARGE TUBE

BRAZING

Compliant Scroll compressors have copper plated steel

suction and discharge tubes. These tubes are far more

rugged and less prone to leaks than copper tubes used on

other compressors. Due to different thermal properties of

steel and copper, brazing procedures may have to be

changed from those commonly used.

•

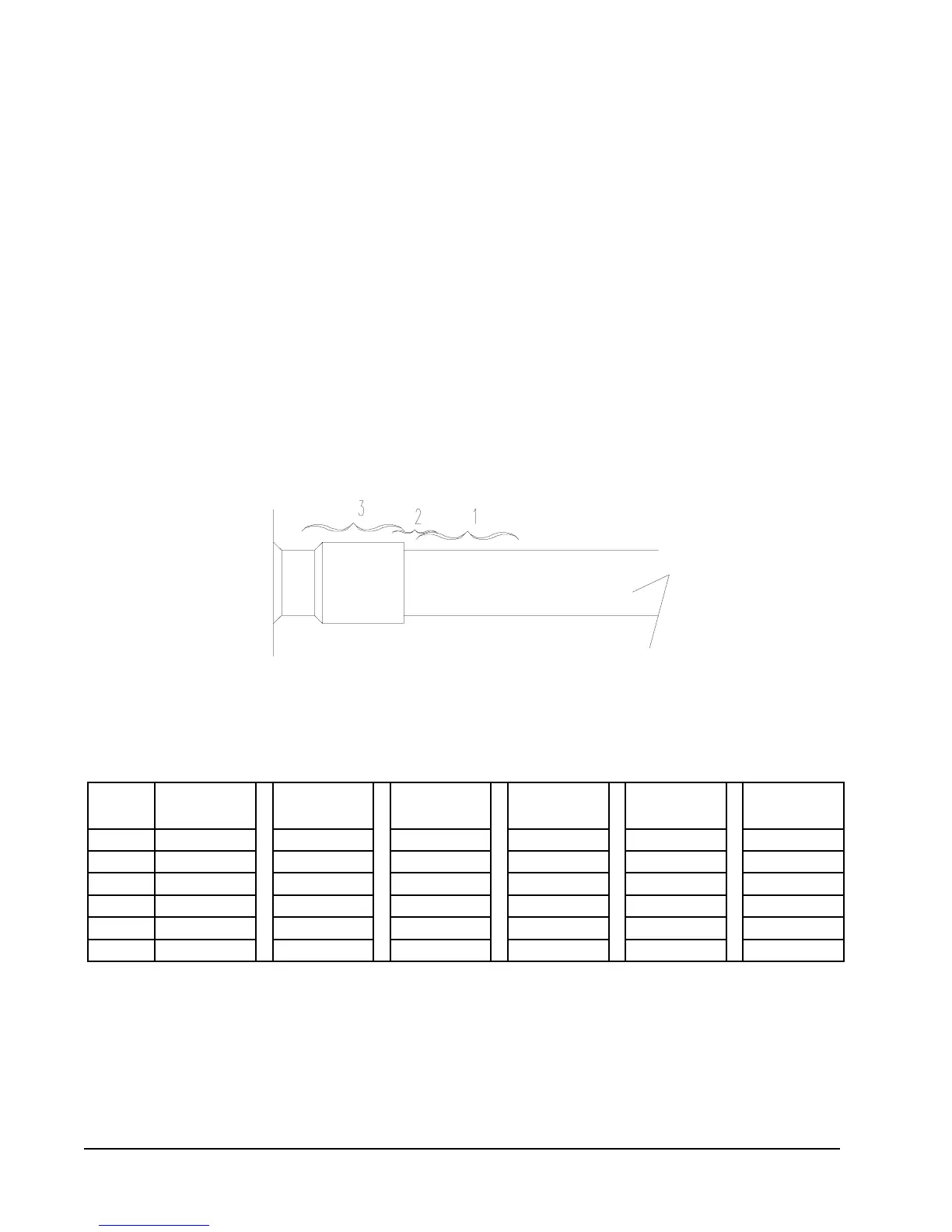

To disconnect: heat joint Areas 2 and 3 slowly and

uniformly until braze material softens and the tube can

be pulled out of suction fitting. (See Figure 14.)

•

To connect:

– Recommended brazing materials: silfos with

minimum 5% silver or silver braze material with

flux.

– Reinsert tube into fitting.

– Heat tube uniformly in Area 1 moving slowly to

Area 2. When joint reaches brazing temperature,

apply brazing material. (See Figure 14.)

– Heat joint uniformly around the circumference to

flow braze material completely around the joint.

– Slowly move torch into Area 3 to draw braze

material into joint. (See Figure 14.)

– Do not overheat joint.

MIS-1179

FIGURE 14

BRAZING DIAGRAM

TABLE 15

INDOOR BLOWER PERFOMANCE

/ niPSE/

H

2

0

4211HP

lioCteW/yrD

0311HP

lioCteW/yrD

6311HP

lioCteW/yrD

2411HP

lioCteW/yrD

8401HP

lioCteW/yrD

0601HP

lioCteW/yrD

0.0/519009/02310521/02310521/05615261/05910291/05810581

1.0/068538/08215711/08215711/00515251/06810381/00810871

2.0/518008/03210011/03210011/53410041/08710571/52710071

3.0/587057/08110001/08110001/04310131/08610661/06615261

4.0/057017/0311059/0311059/03210121/08510551/08510451

5.0/047007/0701098/0701098/02110001/00510841AN

Loading...

Loading...