SURFACE PREPARATION SYSTEM OWNER’S MANUAL & PARTS BOOK

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-5400 FAX 732-566-5444

- 10 -

GENERAL APPLICATION

ADHESIVES – CARPET

R120 (B-1 Cutters)

For the removal of most carpet adhesives.

Estimated Production Rates: 100-300 sq.ft/hr

Estimated Cutter Life: 1200-1500 sq.ft

ADHESIVES – TILE

R138 (A-3, B-3 Cutters)

For the removal of most tile adhesives.

Estimated Production Rates: 100-250 sq.ft/hr

Estimated Cutter Life: 1200-1500 sq.ft

CONCRETE GRINDING

R150, R151, or R152 (Carbide Cutters)

For the smoothing of rough concrete and/or grinding

of high spots.

Estimated Production Rates: 200-500 sq.ft/hr

Estimated Cutter Life: 3000-6000 sq.ft

CONCRETE SCARIFYING/GRINDING

R134 or R139 (Tungsten Carbide Tipped

Cutters)

For preparation of concrete prior to the application of

coatings or concrete overlay (1/8” depth of cut per

pass.).

Estimated Production Rates: 200-400 sq.ft/hr

Estimated Cutter Life: 8000-15,000 sq.ft

LINE REMOVAL

R132 (B-2)

For the removal of painted lines from concrete or

asphalt.

Estimated Production Rates: 10-20 linear ft/min

Estimated Cutter Life: 800-2000 linear ft.

LINE REMOVAL – THERMOPLASTIC

R143 (B-3)

For the removal of thermoplastic based paints from

concrete or asphalt.

Estimated Production Rates: 10-20 linear ft/min

Estimated Cutter Life: 800-1200 linear ft.

TYPICAL APPLICATIONS

Asphalt leveling and grooving

Carpet backing removal

Coating removal

Concrete grinding

Concrete & steel surface preparation

Concrete grooving

Epoxy removal

Expansion joint leveling

Floor cleaning steel & concrete

Glue/adhesive removal

Milling joints

TYPICAL APPLICATIONS (Cont.)

Non-slip removal

Paint removal

Steel de-scaling

Traffic line removal

Wheelchair ramp leveling

ASSEMBLY INSTRUCTIONS

Your new Bartell Surface Preparation System has been

shipped to you fully assembled with some exceptions.

Gas powered units require only filling with fuel and a

brief check of lubricant levels in preparation for

operation. Engine crank case is not pre-serviced with oil

at the factory: levels should be checked. Electric Power

Units are pre-wired at the factory and require only

properly sized extension cable and fusing to comply with

local by-laws.

To facilitate assembly of handles for various models

together with the respective kill switch, electric harness

or air valve, see the appropriate section for your

machine.

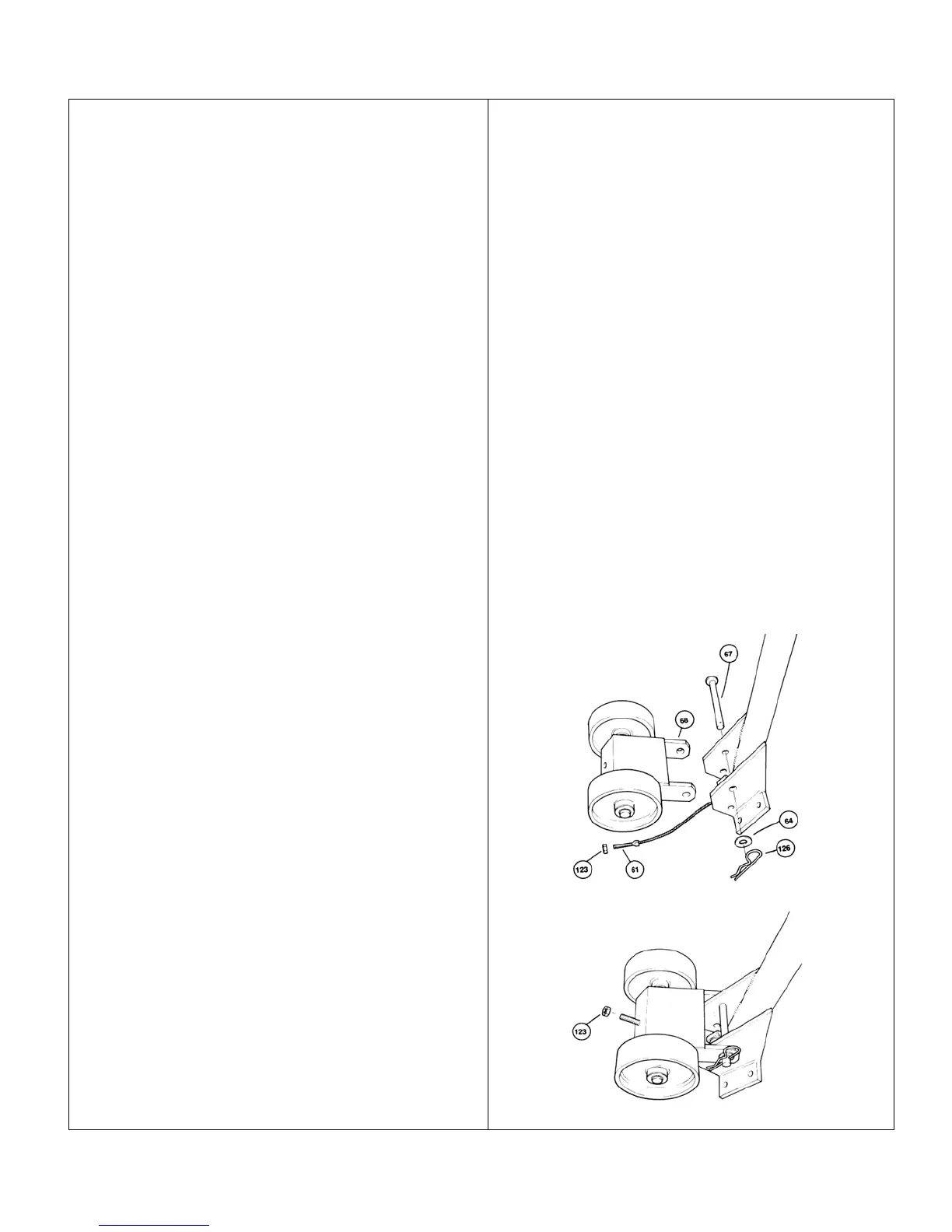

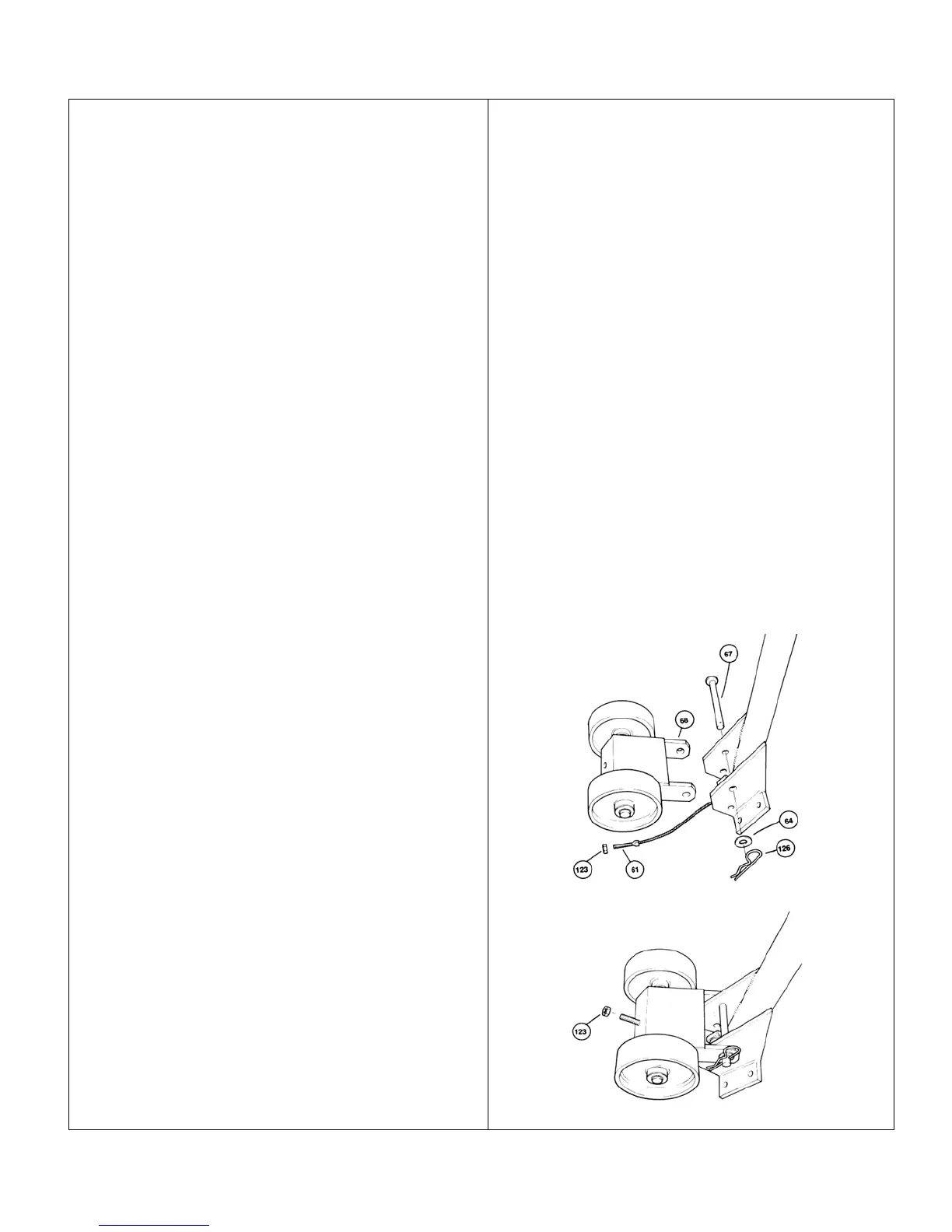

1) HANDLE INSTALLATION

a. Remove the pin (67) from the handle assembly.

Align the lift plate (68) and re-insert the top pin

(67). Place flat washer (64) on pin. Insert spring

clip (126) through hole in pin. Feed threaded

bolt end of cable (61) through hole on lift plates.

b. Tighten cable by attaching nut (123).

Loading...

Loading...