SURFACE PREPARATION SYSTEM OWNER’S MANUAL & PARTS BOOK

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-5400 FAX 732-566-5444

- 13 -

BEARING REPLACEMENT PROCEDURES

IMPORTANT: Disengage power supply. Do not attempt

replacement while machine is operable.

A)

3BSEALED BEARING REPLACEMENT – OUTBOARD

SIDE

4BRemove drive shaft and cutter cage assembly as per

cutter change procedure below. Loosen and remove

bearing block flange by removing screws and

lockwashers. Using a soft drift, drive out and remove

old bearing. Clean parts which will be re-used.

Carefully press new bearing into flange. Take extreme

care to maintain aligned installation. Do not press

sleeve into position if misaligned. Mount bearing block

to side of housing and tighten bolts when bearing

block is in a free spin position.

B) 5BBEARING REPLACEMENT – DRIVER OR “V” BELT

SIDE

Remove belt guard and “V” belt. Loosen two set

screws, remove pulley and remove key. Remove

bearing block assembly by removing screws and lock

washers. Remove snap ring and slip ring. Using a soft

drift, drive out spindle. Take care not to burr or flare

spindle. Remove cover plate being certain the plate

fits flush. Carefully press new bearing into block,

clean and install bearing cover plate. Press drive

spindle into block. Install slip ring and snap ring.

Center and install spindle assembly to housing. Re-

install pulley and key. Ensure pulley butts flush

against shoulder or spindle. NOTE: When removing

spindle or sleeve, care must be taken not to damage

or distort these parts. A soft drift is recommended to

prevent damage.

CUTTER CAGE REMOVAL & CUTTER CHANGE

To remove the cutter cage from the machine.

1. Make sure that the power source is disconnected.

With gas models turn off fuel supply to engine and

disconnect sparkplug; unplug electric unit; disconnect

air supply on air unit.

2. Tilt machine back onto the handle. (If your unit is

equipped with a Honda GX engine, unit must be tilted

forward to change cutters or cylinders will be flooded

with oil).

CUTTER CAGE REMOVAL & CUTTER CHANGE

(Cont.)

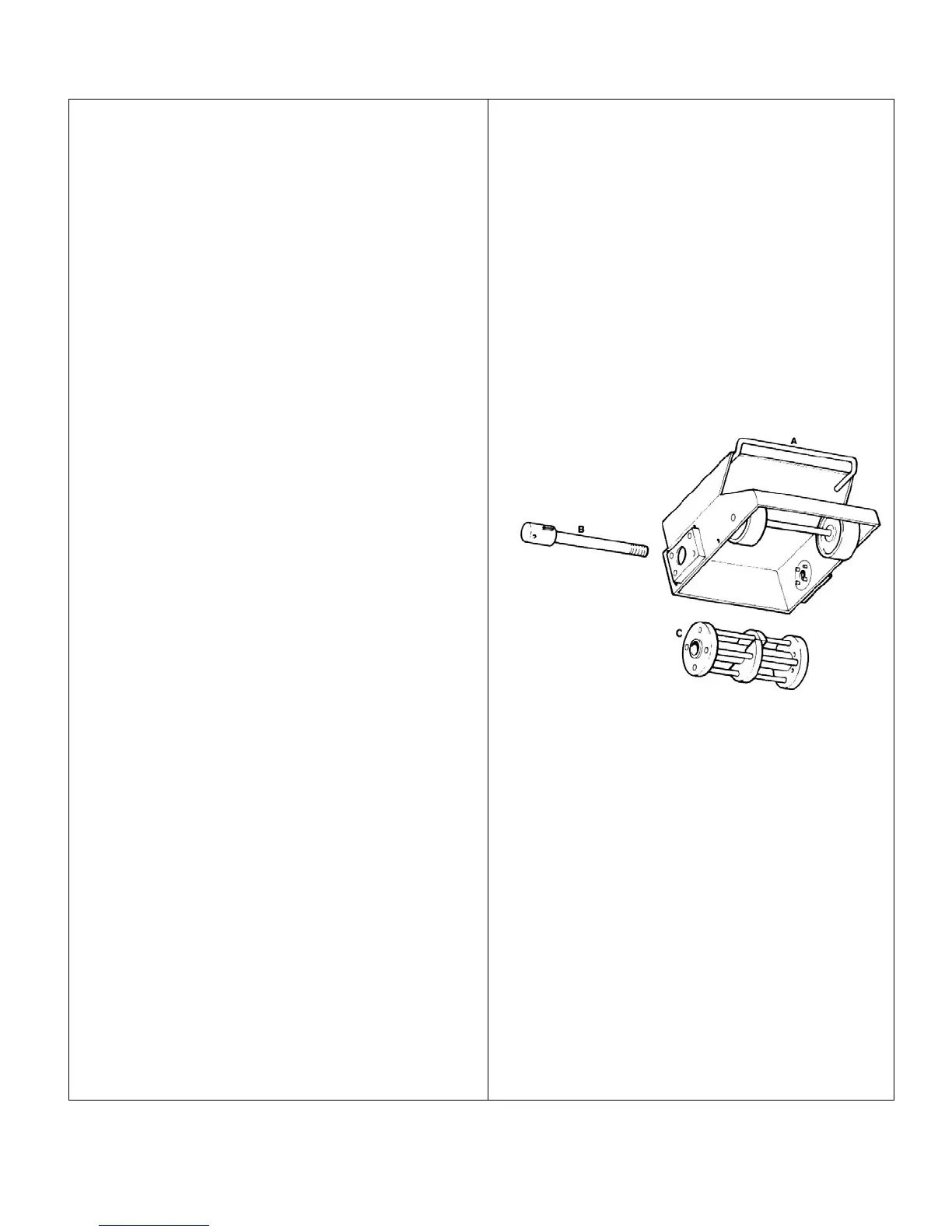

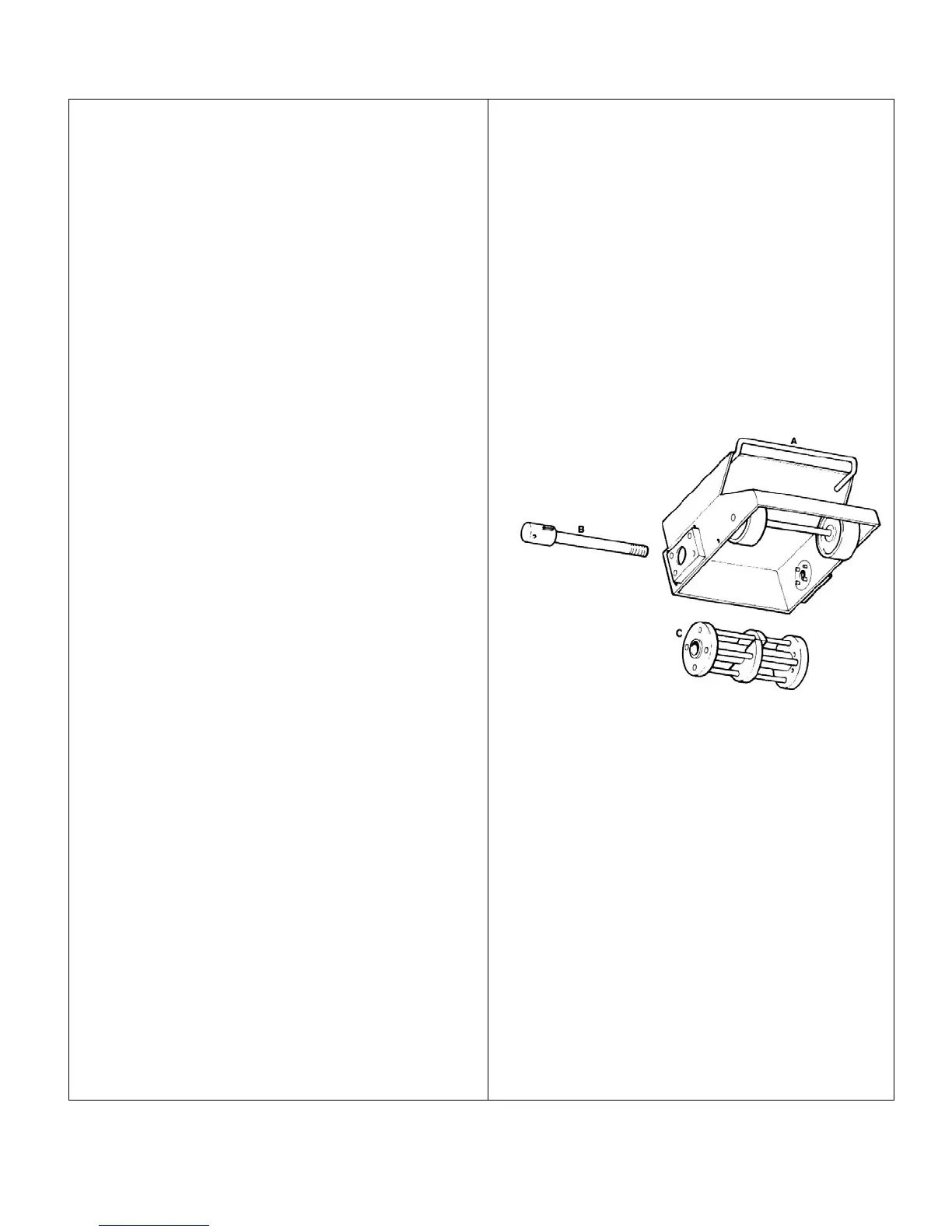

3. Facing the underside of the machine housing (figure

3-A) place a bar between the cutter rods to jam

cage C.

4. Remove end cap and with a 1” (26 mm) socket

loosen and remove the shaft by turning in clockwise

direction.

OR

Remove end cap and shaft guard to insert a drift pin

into the hole on the main shaft B and turn shaft

clockwise to loosen and remove shaft.

5. Disengage the cage from the drive pins by moving

to the left. (The cage on the Honda GX machines

will move to the right). Remove cage.

Figure 3-A

EDGER CAGE REMOVAL

1. Make sure that the power source is disconnected.

With gas models turn off fuel supply to engine and

disconnect sparkplug; unplug electric unit;

disconnect air supply on air unit.

2. Tilt machine back onto handle. (If your unit is

equipped with a Honda GX engine, unit must be

tilted forward to change cutters or cylinders will be

flooded with oil).

3. Using a 15/16” socket or wrench, turn head of shaft

(G) clockwise to loosen.

4. While turning the shaft outwards, cage will move

towards the outer edge as well. Free cage from

locking pins on shaft by pushing cage back towards

main housing (A). turn shaft out and move.

5. Cage will be free to remove from edger.

Loading...

Loading...