13

INSTALLER Section (en)

7710400 (01-06/18)

12.4 COMBUSTION TEST (CO

2

%)

For correct boiler operation, the content of (CO

2

- O

2

) in the combustion fumes must observe the tolerances indicated in the

following table. If the value of (CO

2

- O

2

) is different, check the electrodes and their relative distances. If necessary, replace the

electrodes and position them correctly. If the problem persists, use the following function.

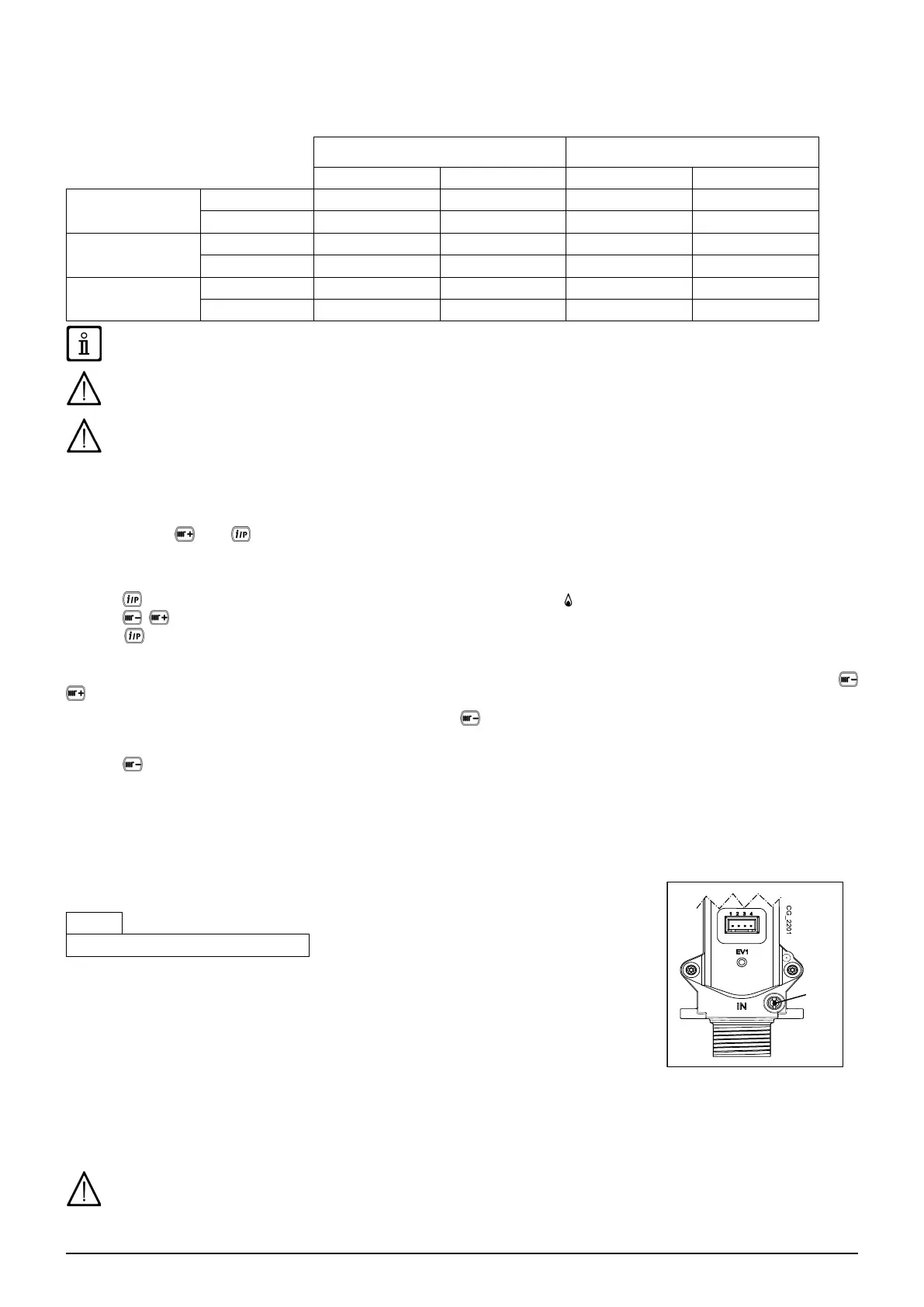

G20 G31

CO

2

% O

2

% CO

2

% O

2

%

Maximum power

Nominal value 8.7 5.4 10.0 6.0

Permitted value 8.2 - 9.3 6.3 - 4.3 9.5 - 10.5 6.8 - 5.2

Ignition power

Nominal value 8.7 5.4 10.8 4.8

Permitted value 8.2 - 9.3 6.3 - 4.3 10.3 - 11.3 5.5 - 4.1

Minimum power

Nominal value 8.8 5.2 10.0 6.0

Permitted value 8.2 - 9.3 6.3 - 4.3 9.5 - 10.5 6.8 - 5.2

The

CO

2

/O

2

values are with the cover closed.

The combustions analisys shall be done using an analyzer regularly calibrated.

During normal operation the boiler performs combustion control cycles. In this phase, CO values higher than 1000 ppm can

occur for brief periods of time.

COMBUSTION ADJUSTMENT FUNCTION (CO

2

%)

This function sets out to partially adjust the value of CO

2

%. The following procedure is used.

• Press buttons and together for at least 6 seconds. When the function is enabled, the displays shows “On” for a few

seconds followed by programme row “304” alternated with the % of boiler power.

• After the burner is lit, the boiler reverts to maximum DHW power (100). When the display shows "100" it is possible to partially

adjust the value of CO

2

%;

• press

. The display shows "00" alternating with the function number "304" ( ashes);

• press

to raise or lower the amount of CO

2

(from -5 to +5).

• press

to save the new value and view the power value "100" on the display again (the boiler continues operating at

maximum DHW power).

This procedure can also be used to adjust the quantity of CO

2

to the ignition power and to the minimum power by pressing

after point 5 of the procedure described above.

• After saving the new value (point 5 of the procedure), press to take the boiler to its ignition power. Wait for the value of

CO

2

to stabilise and then adjust as described in point 4 of the procedure (the power value is a number <> 100 and <> 0) then

save (point 5).

• press

again to take the boiler to minimum power. Wait for the value of CO

2

to stabilise and then adjust as described in

point 4 of the procedure (power value = 00);

• to exit the function, press the buttons for at least 6 seconds as described in point 1.

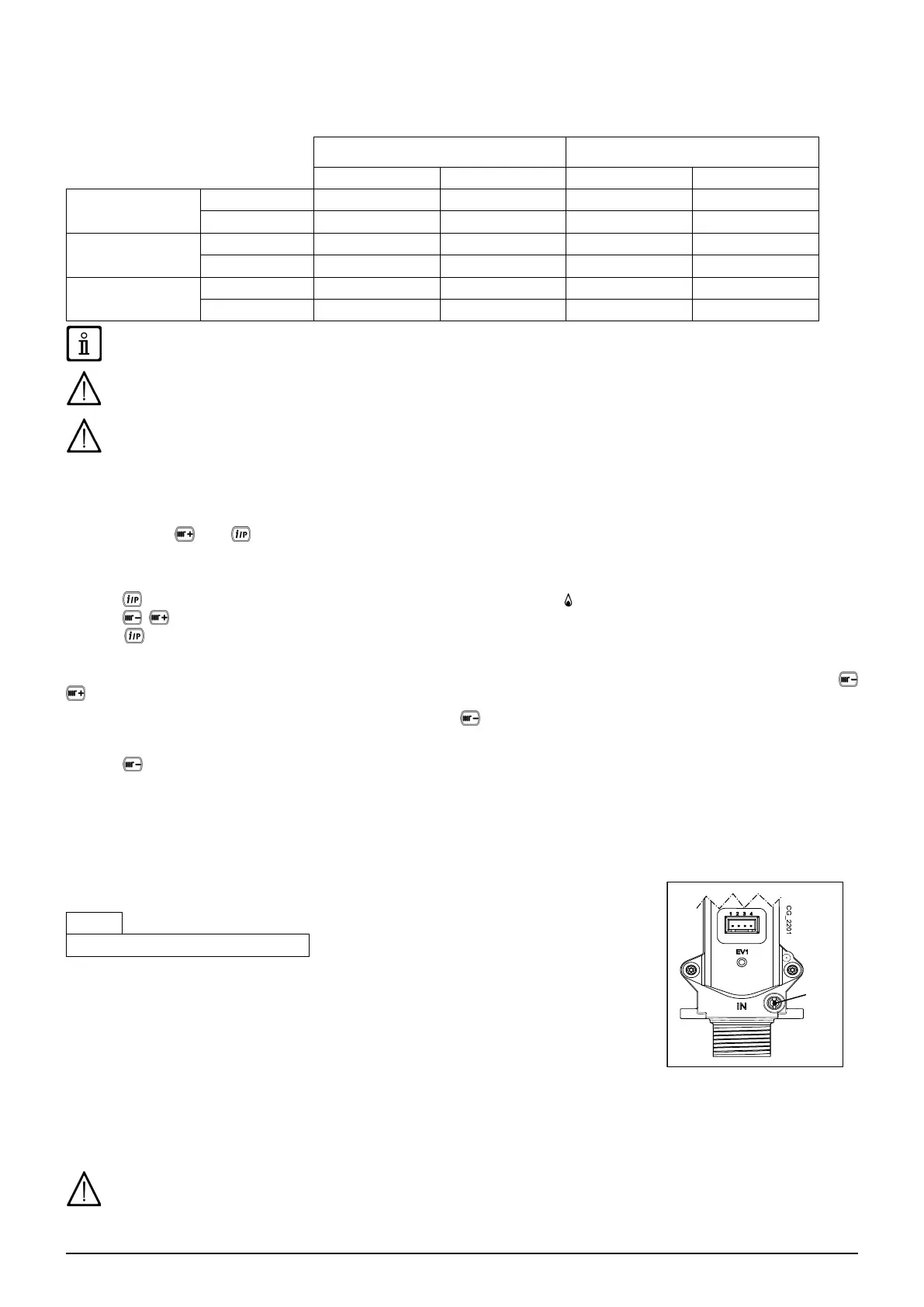

13. GAS VALVE

This appliance does not require any mechanical adjustment on the valve. The system ensures electronic auto-adaptation.

Gas valve key

Pi

Gas supply inlet pressure tap

13.1 GAS CONVERSION METHODS

Only an Authorised Technical Assistance Service can convert boiler operation from NATURAL GAS to LPG or vice-versa. To

perform calibration, set parameter P02 as described in the PARAMETER SETTINGS section. Lastly, check the combustion

parameters as described in the SPECIAL FUNCTIONS - CHECKING COMBUSTION PARAMETERS section.

When the gas change is completed the boiler data plate must be amended to indicate the new gas data.

Pi

Loading...

Loading...