7710400 (01-06/18) 6

USER Section (en)

2. PROLONGED SHUTDOWN. ANTI-FREEZE PROTECTION

Do not drain the whole system as lling up with water again could cause unnecessary and harmful scale to build up inside the

boiler and the heating elements. If the boiler is not used during winter and is therefore exposed to the danger of frost, add some

specic anti-freeze to the water in the system (e.g.: propylene glycol coupled with corrosion and scale inhibitors). The electronic

boiler management system includes a “frost protection” function for the heating system which, when delivery temperature falls

below 5°C, lights the burner until a delivery temperature of 30°C is reached.

The function is operative if: the boiler is electrically powered, there is gas, system pressure is normal and the boiler is not

blocked.

3. GAS CONVERSION

The boilers can operate both on natural gas (G20) and LPG (G31). All gas conversions must be made by the AUTHORISED

TECHNICAL SERVICE CENTRE.

4. FAULTS

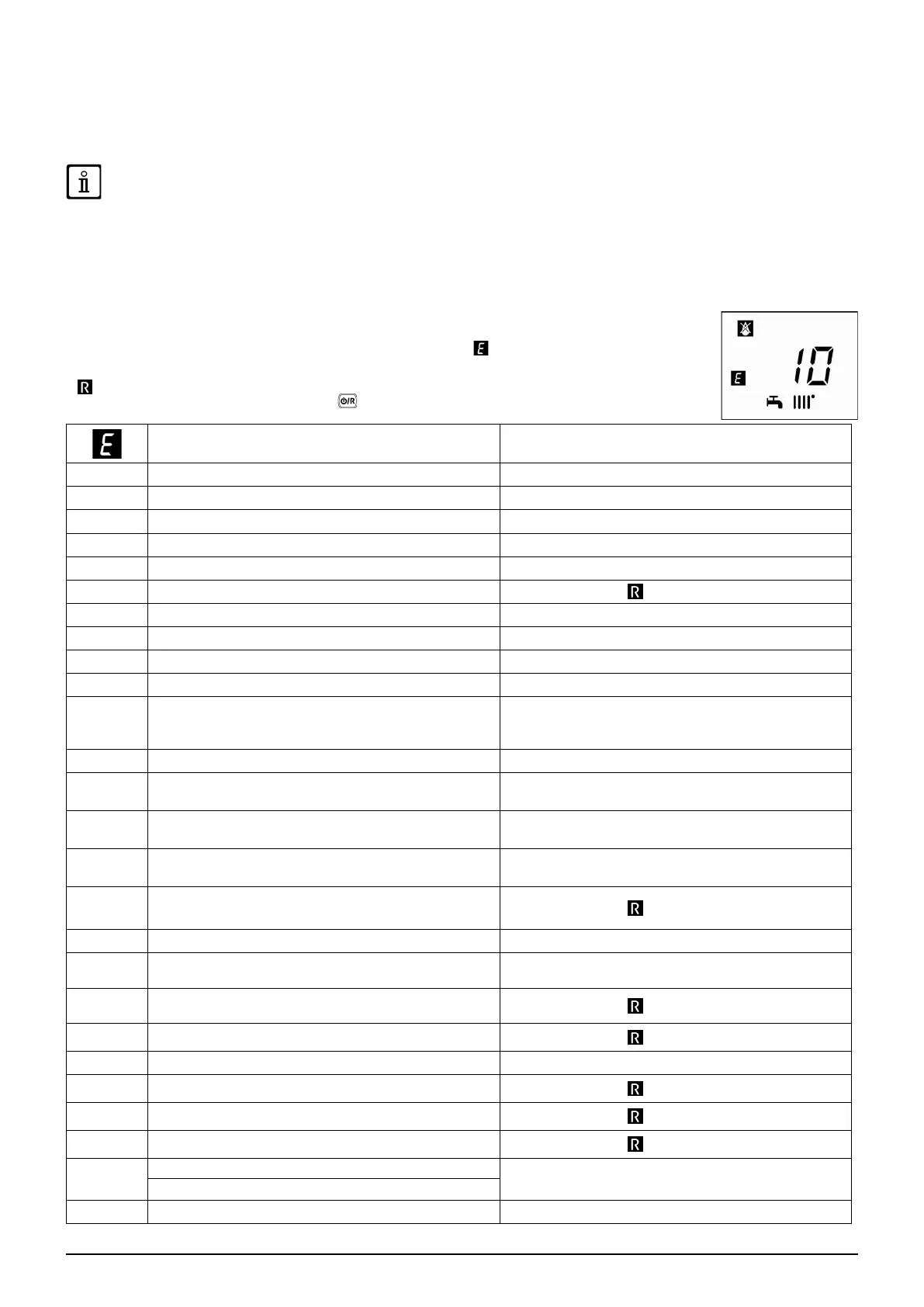

The faults shown on the display are identied with the symbol and a number (fault code). For a

complete list of faults, see the following table.

If appears on the display the fault must be RESET by the user.

To RESET the boiler, press and hold down for 2 seconds. If faults are displayed frequently, call the

Authorised Service Centre.

Description of fault Action

10

External probe sensor faulty Call the Authorised Service Centre.

12

Hydraulic differential pressure switch switching failure Call the Authorised Service Centre.

13

Hydraulic differential pressure switch contacts stuck Call the Authorised Service Centre.

15

Gas valve control error Call the Authorised Service Centre.

18

Hydraulic circuit automatic lling in progress Wait for the end of the lling cycle

19

Fault in system lling phase

Press and hold down

for at least 2 seconds.

20

NTC ow sensor faulty Call the Authorised Service Centre.

28

NTC fumes sensor faulty Call the Authorised Service Centre.

40

NTC return sensor faulty Call the Authorised Service Centre.

50

NTC domestic hot water sensor faulty Call the Authorised Service Centre.

53

Fumes outlet obstructed

Disconnect the boiler from the mains power supply

for a few seconds.

If the fault persists, call the authorised

technical service centre

55

Electronic board not calibrated Call the Authorised Service Centre.

83…87

Communication problem between boiler board and control

unit. Probable short circuit on wiring.

Call the Authorised Service Centre.

92

Fumes fault during calibration (probable fumes

recirculation)

Call the Authorised Service Centre.

109

Air in boiler circuit

(temporary fault)

Call the Authorised Service Centre.

110

Safety thermostat tripped due to overtemperature (pump

probably blocked or air in heating circuit).

Press and hold down

for at least 2 seconds.

117

Pressure in hydraulic circuit too high (> 2,7 bar) Call the Authorised Service Centre.

118

Pressure in hydraulic circuit too low

Check that the pressure in the system is correct; See the

FILLING THE SYSTEM section.

125

No circulation safety trip

(control performed via a temperature sensor)

Press and hold down

for at least 2 seconds.

128

No ame

Press and hold down

for at least 2 seconds.

129

Loss of ame at ignition Call the Authorised Service Centre.

130

Fumes NTC tripped due to overtemperature

Press and hold down

for at least 2 seconds.

133

Ignition failure (5 attempts)

Press and hold down

for at least 2 seconds.

134

Gas valve blocked

Press and hold down

for at least 2 seconds.

135

Internal board error

Call the Authorised Service Centre.

Gas valve connection error

154

Delivery/return probe control test Call the Authorised Service Centre.

Loading...

Loading...