11

§ 5-2 BATCHING MODES

Batching Modes

1. Customer Programmed Control Mode: Normal Batching

2. Customer Programmed Control Mode: Loss-in-Weight Batching

3. Built-in Automatic Program Mode: Normal Batching

4. Built-in Automatic Program Mode: Loss-in weight Batching

5. Multiple-Ingredient Batching

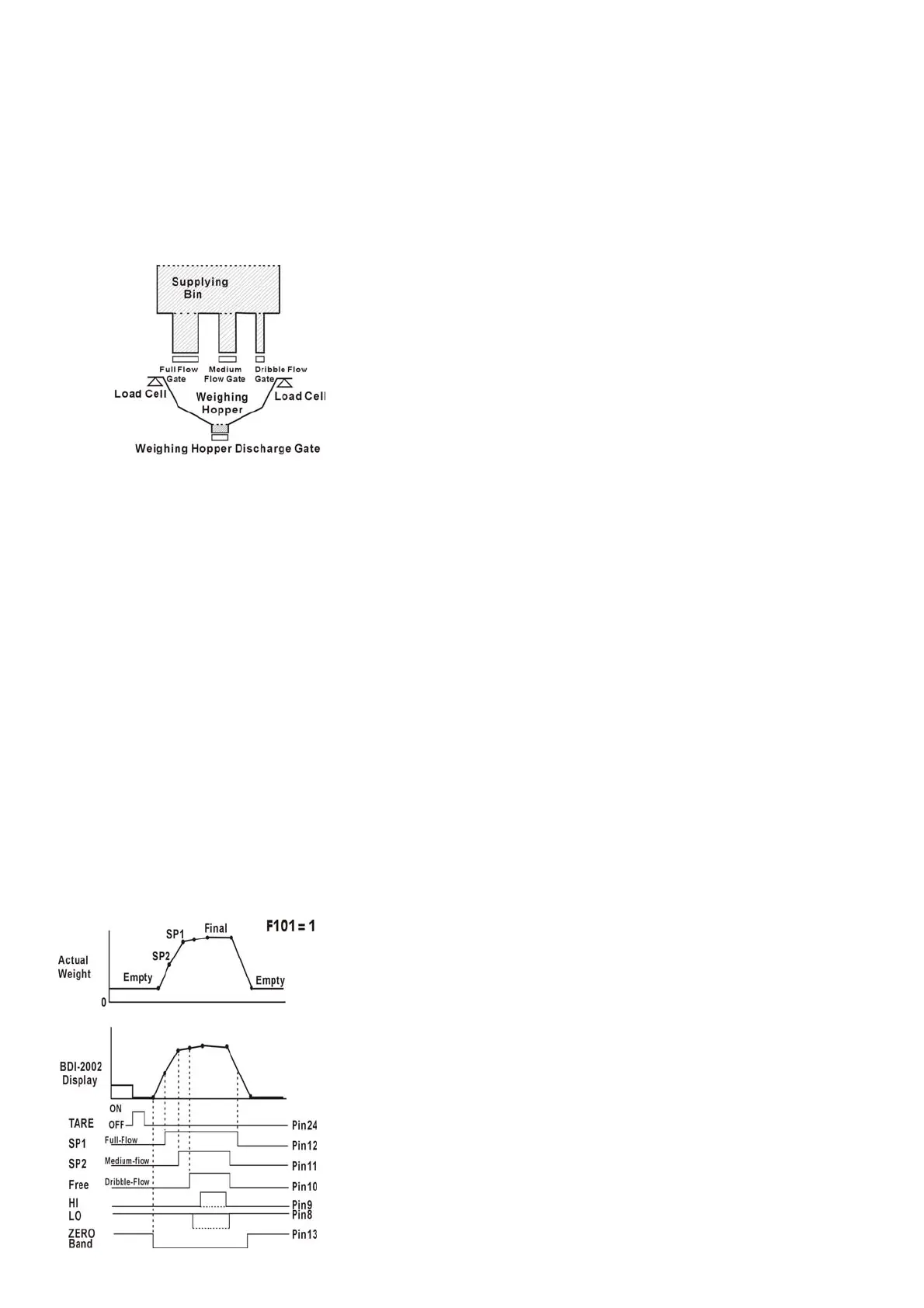

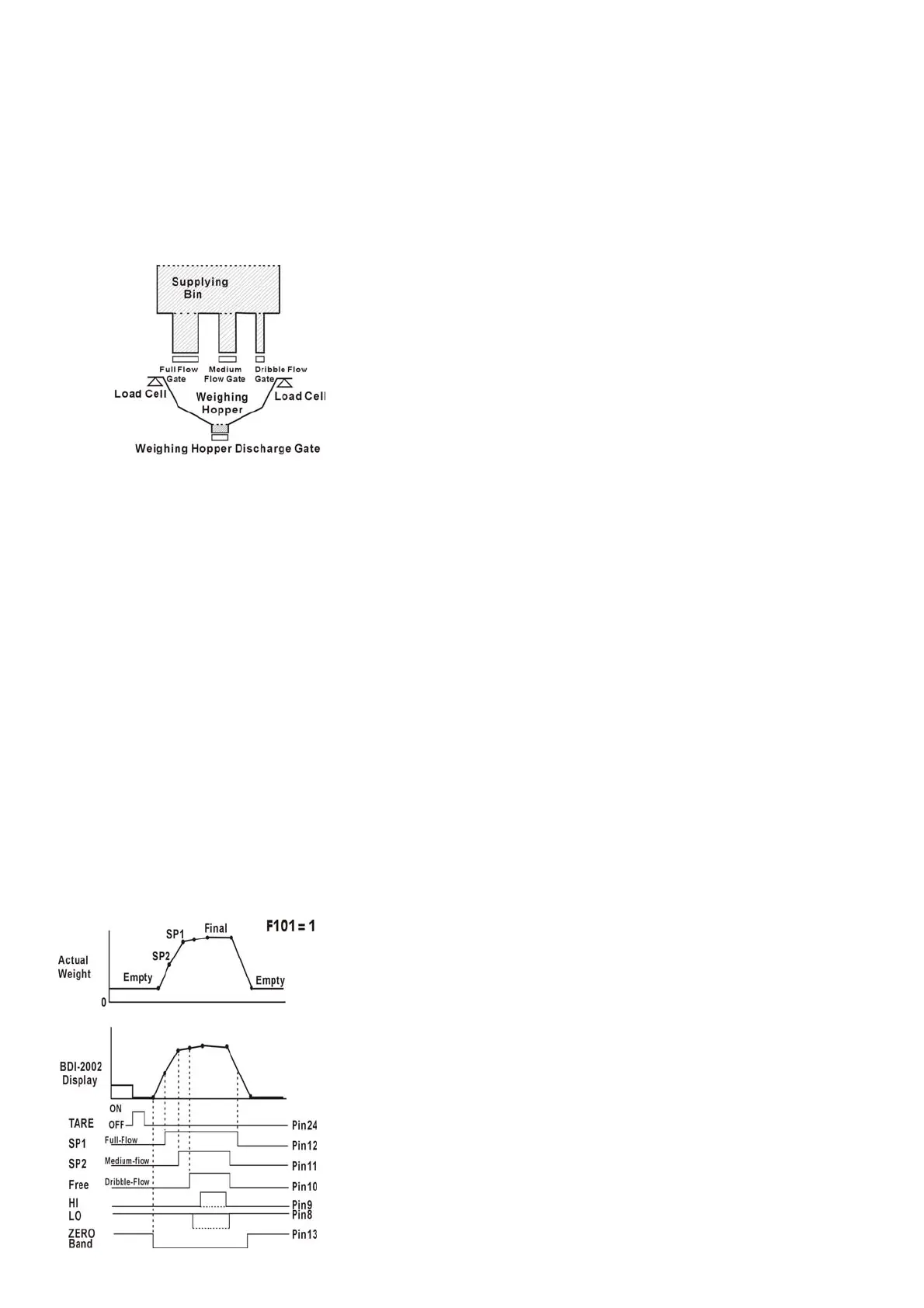

◎ Customer Programmed Control Mode: Normal Batching( F101 = 1)

SP1 – Full Flow Gate

SP2 – Medium Flow Gate

Free – Dribble Flow Gate

1.The Weighing Hopper is empty, the display shows "0", and all Gates are closed. If the

display is not at ZERO, input a TARE signal(Pin 24) to re-ZERO the display.

2.Open the Supply Bin's: Full-Flow Gate,Medium-Flow Gate, and Dribble-Flow Gate.

3.When the display reaches "Final - SP 1", the SP 1 Output (Pin 12) signal will come ON.

Closed the Full-Flow Gate by using the SP 1Output ON signal.

4.When the display reaches "Final - SP 2", the SP 2 Output (Pin 11) signal will come ON.

Closed the Medium-Flow Gate by using the SP 2 Output ON signal.

5.When the display reaches "Final - FREE", the FREE Output (Pin 10) signal will come ON.

Closed the Dribble-Flow Gate by using the FREE Output ON signal.

6.After Free Fall has stopped - check if the HI and LO (Pin 9, 8) signals are OFF. If both outputs are

OFF then the batch is completed correctly.

7.An Automatic Free Fall Compensation Command (Min. 200ms pulse to Pin 21) may be given at this

time. If you change the Free Fall Set Point value either from the Front Panel or the RS-232C,

RS-422/485-the learned Free Fall value will be cleared.

8.Use the FREE (Pin 10) signal to delay a time period as the control signal is processing empty the

Weighing Hopper.

9.When the GROSS weight is below the ZERO band, the ZERO Band Output will come ON -signifying

the Weighing Hopper is empty. Closed the Weighing Hopper Discharge Gate by using the ZERO

Band (Pin 13) Output ON signal.

10.You are now ready for your next batching event.

Loading...

Loading...