12

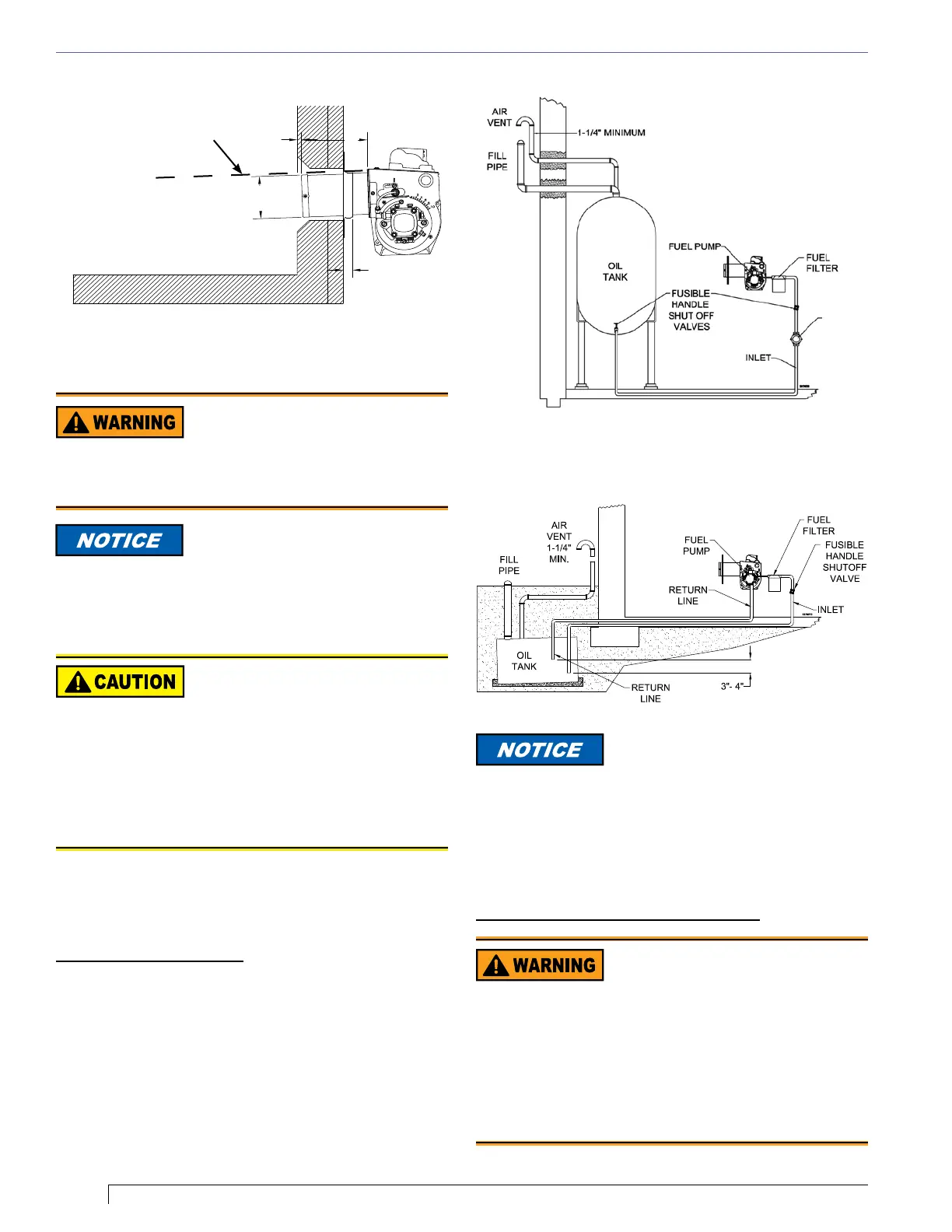

Installing the Oil Tank and Supply System

Fuel supply level with or above burner

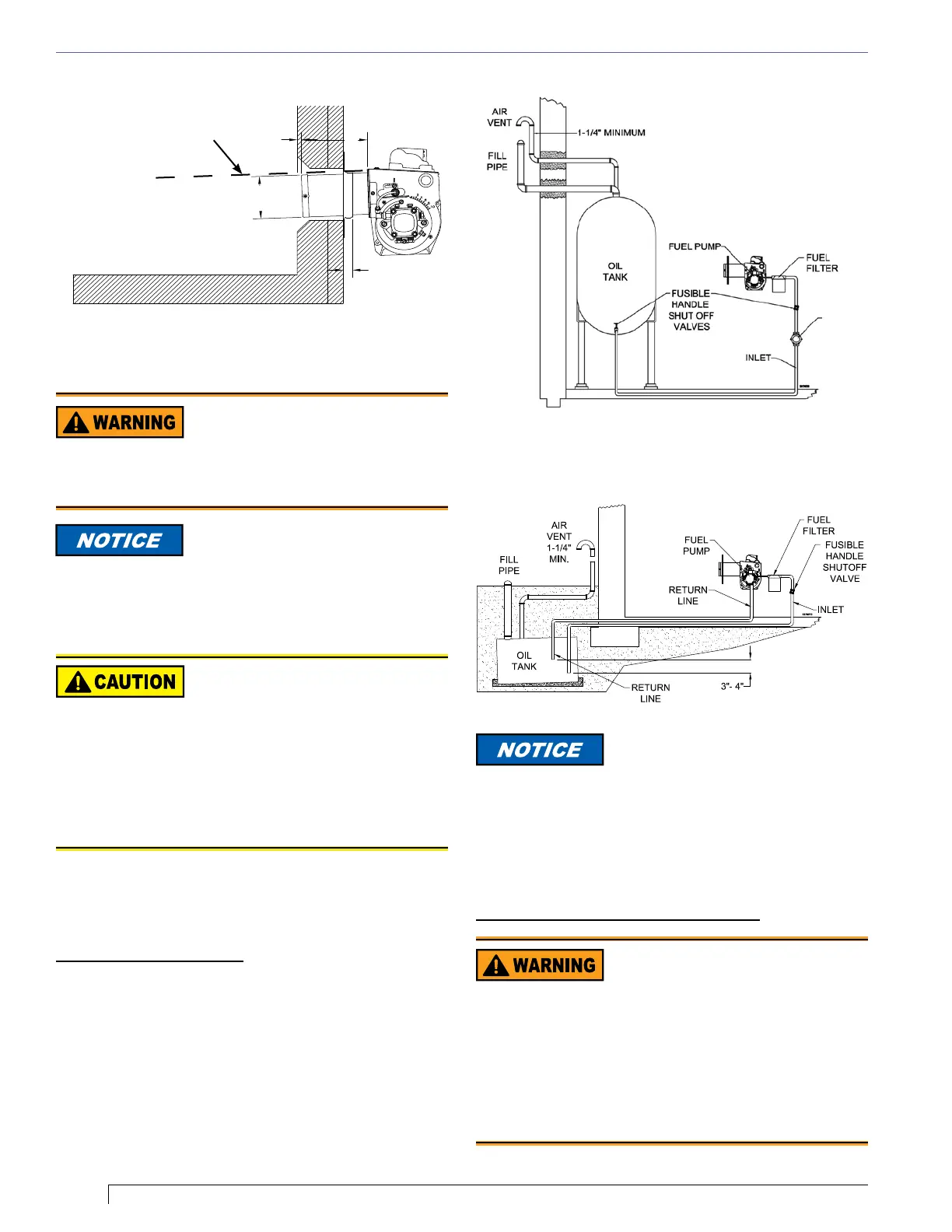

Figure 14. – Mounting Burner in Appliance Figure 15. – Inside Tank Gravity Feed System

Figure 16. – Outside Buried Tank-Lift System

Note: to determine the proper fuel line size, refer to the

fuel pump manufacturer’s instructions provided with

the burner. Refer to Figure 15 or Figure 16 for typical

installation layouts.

Fuel Line Valves and Filter

Install two high quality, oil duty rated, fusible handle design

shutoff valves in accessible locations on the oil supply line.

Locate one close to the tank and the other close to the

burner, upstream of the lter for service access. Refer to

NFPA 31 or the AHJ for further information regarding the

placement of oil safety valves in the fuel supply system.

Install a generous capacity lter inside the building between

the fuel tank shutoff valve and the burner, locating both the

lter and the valve close to the burner for ease of servicing.

Filter should be rated for 50 microns or less.

Section: Mount Burner on Appliance

Oil Leak and Fire Hazard

Install the oil tank following applicable standards in the U.S.

by referring to the latest edition of NFPA 31 or CSA-B139 &

CSA-B140 in Canada, and all authorities having jurisdiction.

y Never use Teon tape on fuel oil ttings.

y Tape fragments can lodge in fuel line components and fuel unit,

damaging the equipment and preventing proper operation.

y Use pipe joint sealant approved for use on kerosene, fuel oils

and biodiesel fuels

.

Damage to the pump could cause impaired burner

operation, oil leakage and appliance soot-up.

Do Not Use Teon Tape

To further protect the fuel supply

system and reduce nozzle orice

plugging with ring rates below 0.75 gph, a dual ltration

system can be installed. This typically consists of a 50

micron primary lter, located near the fuel tank and a

secondary lter rated for at least 10 microns located

near the burner.

y The burner is shipped without the by-pass plug

installed.

y Install the by-pass plug in two-pipe oil supply

systems ONLY.

Failure to comply could cause Immediate pump seal

failure, pressurized oil leakage and the potential for a

re and injury hazard.

Do Not Install By-pass Plug

with 1-Pipe System

SK8745

Tilt down 2

°

If space between burner air

tube and opening exceeds

1/2 inch, pack burner

opening with ceramic fiber

refractory.

4”

1/4”

A

7/8”

Fuel Supply System

Compatibility

The fuel supply system design and components must be

compatible with the fuel being used in the appliance. Follow all

guidelines and best practices recommended by the fuel supplier,

NFPA 30 & NFPA 31, and any state or local ordinances for safe

storage, ltering, conditioning, and delivery to the burner.

ANTI-SYPHON

VALVE

Carefully measure the insertion depth when using

an adjustable flange. Verify the insertion depth when

using a welded flange.

Loading...

Loading...